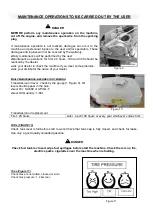

CONTROLS

DRIVING CLUTCH LEVER

Push the lever(1, Figure 1) down to the handlebar to make the

machine moving. Release the lever, then the machine stops.

BLADE CLUTCH LEVER

Blade clutch lever makes the engine drive the blade to

mow.Press the lever (2,Figure 1) then pull the lever (3,Figure

1) to make the blade turning.

Release the lever, then the rotor stops.

WARNING

Never try to start or stop the engine with blade engaged

THROTTLE LEVER

Push the throttle lever(4, Figure 1) to left to increase engine speed, push the throttle lever to right to

decrease engine speed to idle rpm. Always operate mower at full engine speed.

SIDE CLUTCH LEVERS

The side clutch levers (5, Figure 1) are used to change the direction of the machine. Press right lever

to turn right and left lever to turn left. To move the machine when engine is cut off, press the both

levers.

DANGER

Do not press the two levers in slopes when engine is running.

HANDLEBAR ADJUSTMENT LEVERS

Grip the lever ( 6, Figure1) to move handelbar right and left.

And grip the lever ( 7, Figure 1) to move handlebar up/dpwn.

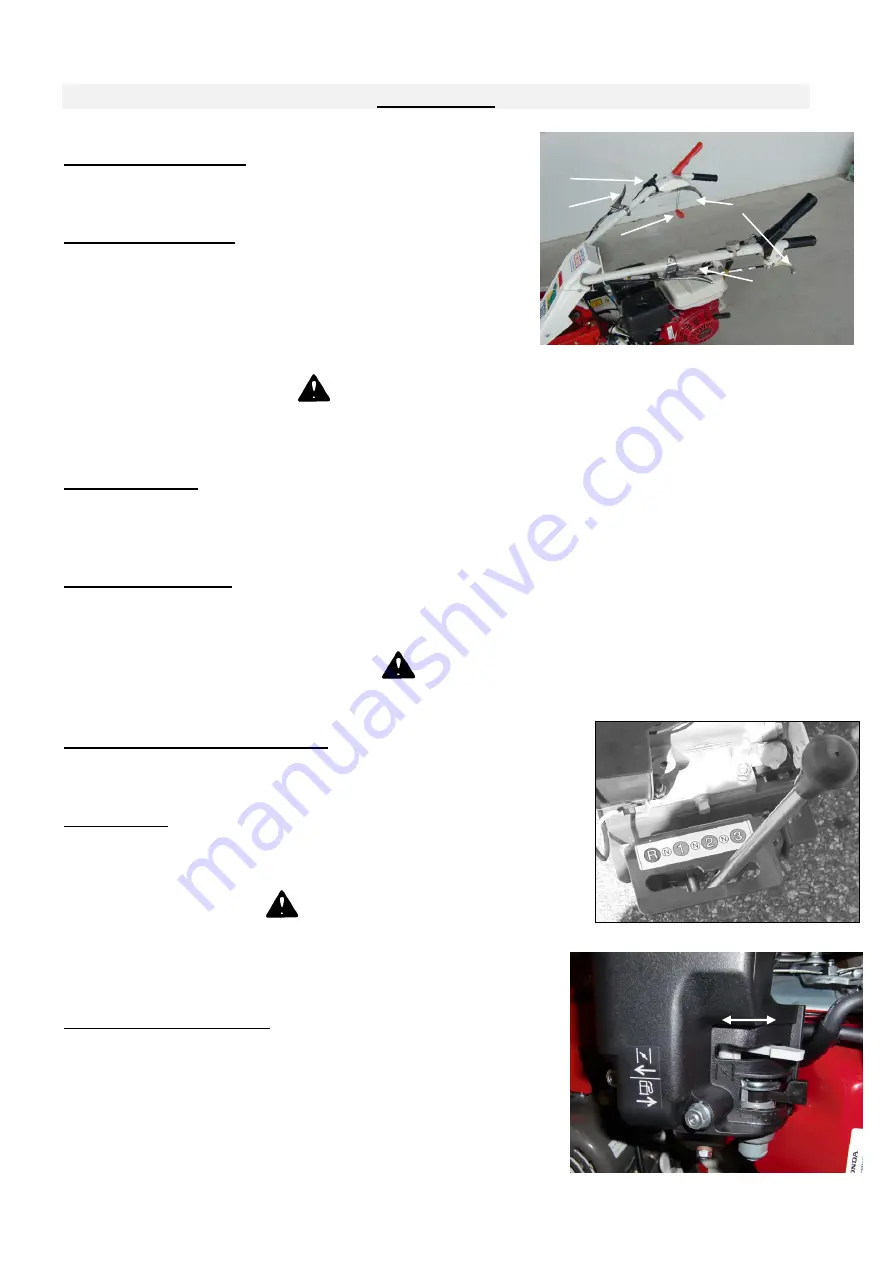

SPEED LEVER

This lever (Figure 2) allows to select 3 forward speeds (1, 2, 3), 1

reverse speed (R) or 3 neutral location (N).

WARNING

Operate speed and range lever only with the machine stopped

and engine at idle speed.

CHOKE LEVER

(1,

F

IGURE

3)

Push the lever to 2 to operate the choke to start engine cold, when

engine has start release it to 3.

IMPORTANT

Do not use the choke when the engine is hot

Figure 2

Figure 3

4

3

5

2

1

7

Figure 3

6

Figure 1

3

2

1