■

Differential locking wire

・

If the machine does not function even when diff lock lever is ON.

- It is necessary to increase the tension on the wire.

First, loosen nut [A] on the right side part of the wire hook

plate and then tighten nut [B] on the left side part of the wire

hook plate.

・

If the machine still functions even when diff lock lever is OFF.

- There is too much tension on the wire.

Loosen the tension on the wire.

Loosen nut [B] on the lower side of the wire hook plate and

then tighten nut [A] on the upper side of the hook plate.

7) Belt Inspection

Please check the blade belt and driving belt regularly as they are consumable parts and subject to wea

and tear. If you notice wear or cracks in any of these parts, please replace immediately.

V-belt: Drive belt--- LA36

Blade belt---LB45

●

Inspection time:

After the first 2-3 hours of operation and then every 30 hours of operation thereafter.

●

Before working on the machine, stop the engine and remove the spark plug cord. Not taking this

precaution could lead to serious injury and accident.

●

Please dispose of used belt properly.

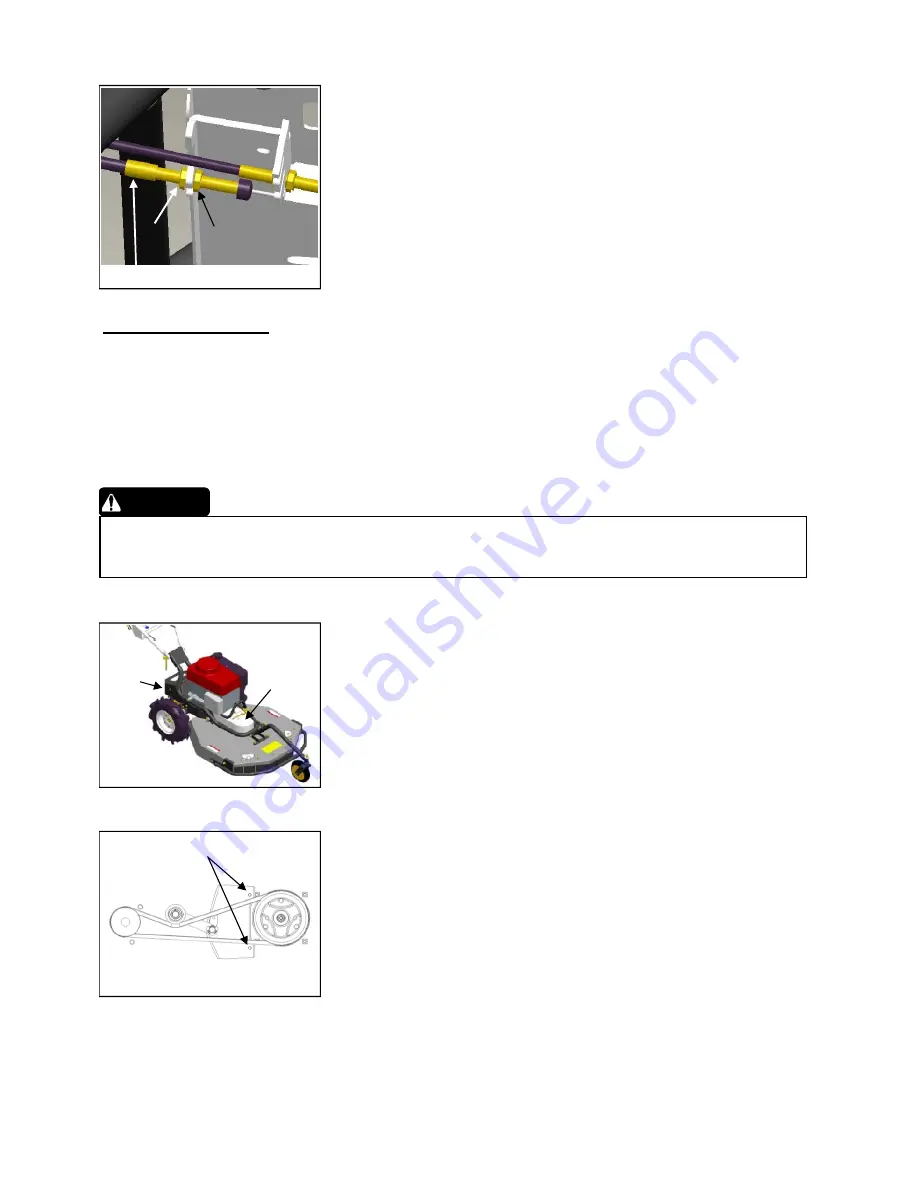

■Before Inspecting the Belts

When inspecting the engine belt,

please be sure to remove the transmission pulley cover [

A

]

When inspecting the blade belt,

please be sure to remove the blade pulley cover [

B

]

■

Inspecting the blade belt

The blade guard has been welded to the machine in order to control it.

1.

Make sure that when the blade clutch lever is [ON], the gap

between the belt and the belt guard is between 2-3mm(0.078-0.11

2.

Release the blade clutch lever [OFF] so that the belt guard only

lightly controls the belt. The belt should now have risen up

above the pulley gutter. Check that the belt does not move

even when you turn the pulley by hand.

Differential locking

A

B

[A]

[B]

WARNING

Blade belt guard

28