9) Inspecting and replacing blades

●

When inspecting or replacing the blade, always be sure to switch off the engine as there is a

danger of injury.

●

When having the blades replaced or repaired, always have any such work performed by a person

with adequate tools and experience.

●

The inspection or replacement of blades should be performed by 2 people. The handlebars

should be held firmly to stop the front of the machine from falling down. Not taking this precaution

can cause injury.

●

To avoid injury, wear safety gloves when performing inspection or replacement and wrap the tips

of the blades in cloth.

●

Replace the blades if you detect any abnormalities. If you neglect wear and tear, cracks, and

bending, there is a danger that the blades could break and fly out of the machine, severely

injuring the operator or any bystanders.

●

When replacing the blades, be sure to also replace the nuts and bolts which tighten the blades.

This prevents accidents caused by wear and tear on the nuts and bolts. Never use nuts and bolts

that are not recommended for this specified purpose.

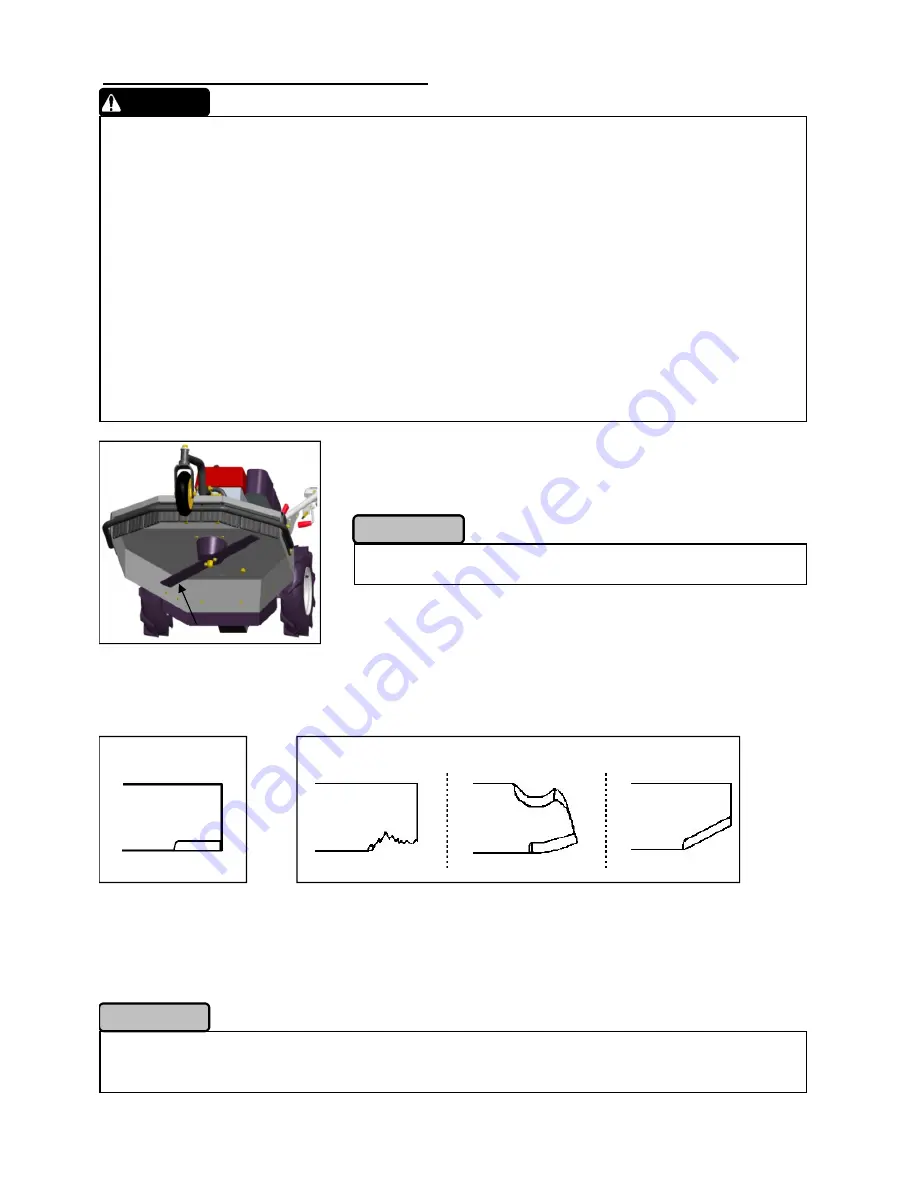

1.

Stop the engine and remove the spark plug cap.

2.

Push the machine's handlebars down to raise the cutting part

of the machine.

●

Do not neglect a decline in the machine’s performance.

Promptly make repairs to avoid permanent damage.

3.

Inspect the blades for cracking, bending, and wear and tear.

If the blades become damaged in the ways shown in the diagram below, have them replaced.

(The blades are attached with 2 attaching bolts and a head bolt.)

4.

Check that the bolts holding the blades in place are not loose.

Note:

M10 bolts tightning torque:

435 lbf

・

in.( 49 N

・

m)

M16 Nut tightning torque:

955 lbf

・

in.(107.8 N

・

m)

●

More frequent inspection the blades is necessary if using the machine on areas including dry

earth and sand which cause faster wear and tear of the blades.

●

We recommend purchasing a spare blade in advance and keeping it in a safe location.

Normal

Damaged Bent Excessively Worn

Blade

WARNING

NOTICE

NOTICE

NOTICE

30