c. Check to see if the blower wheel is adequately supported by the outside bearing

plate assembly.

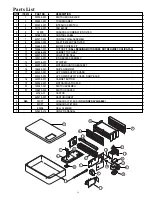

d. Check to see if the motor mounting bracket snap tabs are in place or are loose.

Look into the four base slots to see the tabs.

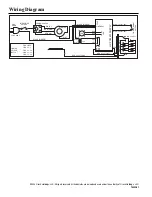

e. Check to see if the motor is loose in the support bracket by holding the bracket

and trying to move the motor. If the motor moves, remove the mounting bracket to

check the isolator pads

11

Troubleshooting Guide

If the tabs are not in position,

use a screwdriver inserted

into slots to push the tabs

out of the slot. You may

need to twist the screwdriver

slightly to disengage the

snaps. Inspect the mounting

bracket; replace it if

damaged. Check for broken

mounting tabs, distorted

bracket (because of

excessive heat). A distorted

motor bracket normally

indicates motor overheating.

The motor should be

replaced.

Insure that the isolator pads

are in position. Replace if the

motor moved while being

held in place with mounting

bracket.

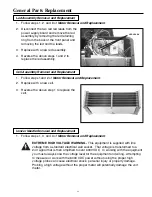

The outboard end of the blower wheel should be

firmly supported, allowing no movement other than

rotation. If that end of the wheel can be moved front

to back and up and down, remove the bearing plate

assembly and check the bearing for damage or

excessive wear. Replace parts as needed. Use care

in handling the blower wheel. Do not distort the

wheel blades. On reassembly, insert the outboard

wheel shaft into the bearing plate then position the

plate into the cabinet. The blower wheel should be

positioned so that the clearance between the ends of

the wheel and the adjacent walls are approximately

equal on both sides. If the wheel is too close it may

drag on the wall. Too much clearance at the outboard

end may cause the wheel shaft to slip out of the

outboard bearing.