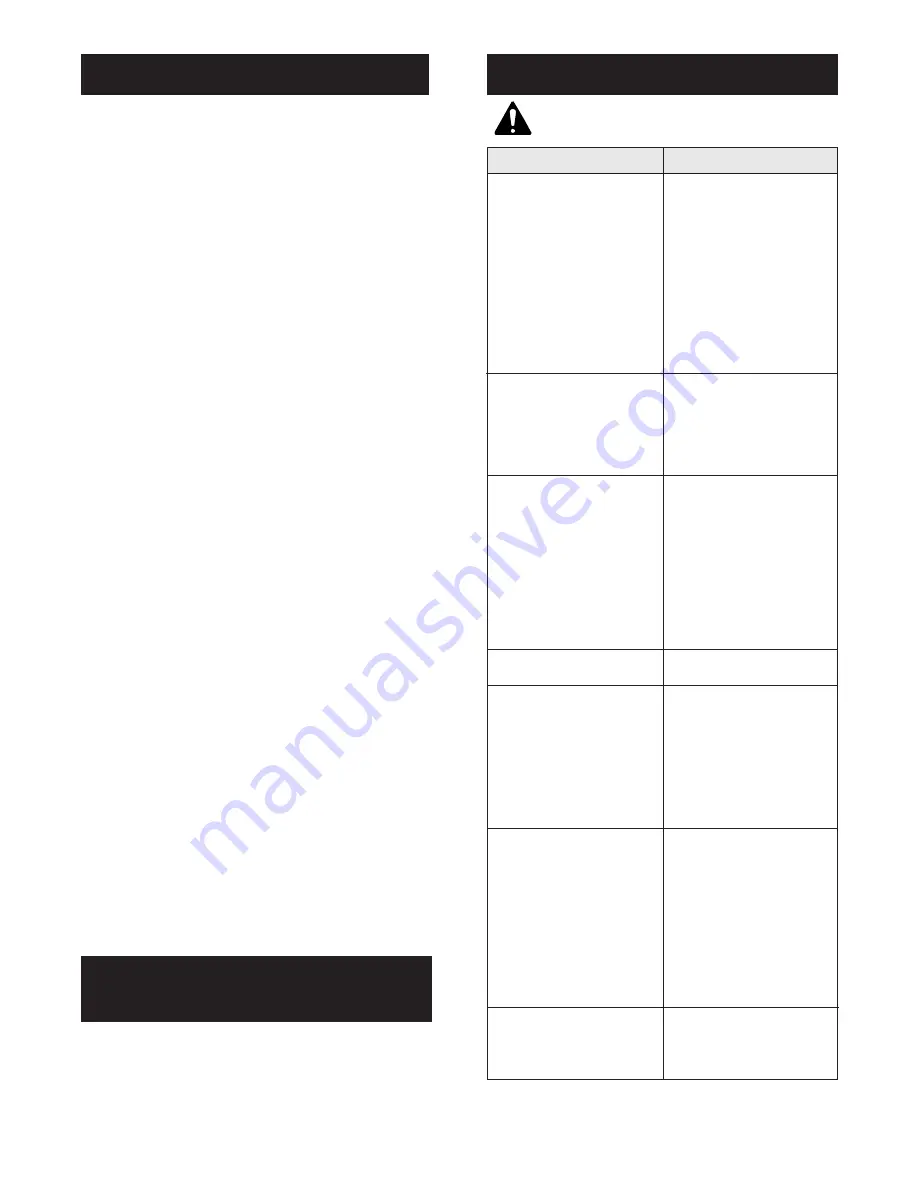

3

Water and cleaning solution

is not dispensing onto carpet

or upholstery.

Not removing certain stains.

Heavy traffic area spots.

Carpet is excessively wet after

cleaning.

Note:

Under normal

conditions, a carpet may take

up to four hours or longer to

completely dry. Drying time

depends on a combination of

various factors including:

carpet type, carpet pile

thickness, temperature,

humidity, air circulation and

the number of wet passes.

Excessive foaming at spray tips.

Dark streaks on carpet after

cleaning.

STEEMER brush roll will

not turn.

Cleaner will not run or

suddenly stops.

• Check that the upper supply tank is partially

filled with lukewarm water. Caution: Do not

overfill.

• Check that a cleaner cartridge is installed and

that the white lever is locked in the downward

position. Due to pressurization, the cleaner will

not properly operate without a cleaner

cartridge in place. If the cleaner cartridge is

empty, replace it with a full cartridge.

• Check that the spray tips are not clogged. Use a

towel or damp cloth to clean.

• For above-the-floor cleaning, check that the

hand-held nozzle and hose assembly is properly

connected to the cleaner neck. Also insure that

the button lock has been engaged.

• For best results, use a stain pretreatment, such

as STEEMER Full Release™ Professional Spot &

Stain PreCleaner. These solutions loosen and

break down most common household grease,

oil, and food stains.

• Make several slow passes over the stain from

different angles.

• Make at least one additional pass over the wet

carpet without pressing the cleaner button.

• Check that the handle trigger lock is not

engaged.

• With each pass, slowly pull the unit toward you

to extract any remaining liquid in the carpet. To

speed drying, gently push the nozzle deep into

the carpet pile.

• Check for airpath obstructions in the

stair/upholstery hose, cleaner neck and in the

nozzle. Check to insure that the inlet screen is

free of debris.

• Check that the upper supply tank has water.

• Operate the machine more slowly; you will

achieve better results with one slow pass than

several fast strokes.

• Overlap each pass to provide maximum

cleaning without streaking.

• In high traffic or heavily soiled carpets, it is

occasionally beneficial to allow the carpet to dry

and repeat the process as needed to achieve

optimal cleaning.

• Check that the STEEMER power cord is

completely connected to the main unit.

• If an obstruction stalls the brush roll, the belt is

designed to burn through so as to protect the

motor. Please insure through inspection that the

brush roll is free of obstructions and is free to

turn. Secondly, make sure that the belt is in

good working order. Replace the belt if needed.

• If the belt and the brush roll become

excessively wet, momentary slippage can occur.

By running the unit on a dry section of carpet

for a minute or less, the belt will function

properly.

• Reinsert the plug, if it has slipped out of the outlet.

• The A.L.C.I. may have tripped off due to

fluctuations in household current. Press the reset

button and restart the unit.

P

ROBLEM

S

OLUTION

W

arranty

ORECK MANUFACTURING COMPANY: (ORECK gives you the

following limited warranty for this product only if it was originally

purchased for use, not resale, from ORECK or an ORECK

Authorized Retail Dealer.)

ORECK will repair or replace, free of charge, to the original

purchaser, any part which is found to be defective in material or

workmanship within one (3) years of the date of purchase. This

limited warranty applies to normal domestic use. Any commercial

use of this product will void this limited warranty.

Drive belts, revolving brushes, bulbs, disposable bags, and other

parts subject to normal wear are not covered by this limited

warranty.

This limited warranty does not apply to any part subjected to

accident, abuse, commercial use, alteration, misuse, damage

caused by fire or act of God, the use of voltages other than

indicated on the serial number plate of this product or service of

this product by other than ORECK or an ORECK Factory

Authorized Service Center.

ORECK does not authorize any person or representative to assume

or grant any other warranty obligation with the sale of this

product.

ORECK’s limited warranty is valid only if you retain proof of

purchase from ORECK or an ORECK Authorized Retail Dealer for

this product. If you purchase this product from any other source,

your purchase is “AS IS,” which means ORECK grants you no

warranty, and that you, not ORECK, assume the entire risk of the

quality and performance of this product, including the entire cost

of any necessary servicing or repairs of any defects.

ORECK’s liability for damages to you for any costs whatsoever

arising out of this statement of limited warranty shall be limited to

the amount paid for this product at the time of original purchase,

and ORECK shall not be liable for any direct, indirect,

consequential or incidental damages arising out of the use or

inability to use this product.

Some states do not allow the exclusion or limitation of incidental

or consequential damages, so the above limitation or exclusion

may not apply to you.

ALL EXPRESS AND IMPLIED WARRANTIES FOR THIS PRODUCT,

INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED IN

DURATION TO THE WARRANTY PERIOD, AND NO

WARRANTIES, WHETHER EXPRESS OR IMPLIED, WILL APPLY

AFTER THIS PERIOD.

Some states do not allow limitations on the duration of implied

warranties, so the above limitation may not apply to you.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

T

roubleshooting

G

uide

Whenever calling, please be sure to have your model and

serial number from data plate.

CALL CUSTOMER SERVICE HOT LINE

US: 1-800-989-3535

CANADA: 1-888-676-7325

ALL OTHER SERVICING SHOULD BE DONE BY AN

ORECK AUTHORIZED SERVICE CENTER.

WARNING: Unplug cord from

electrical outlet before servicing.