20

12.07/WE

ORGAPACK OR-P 400 HD

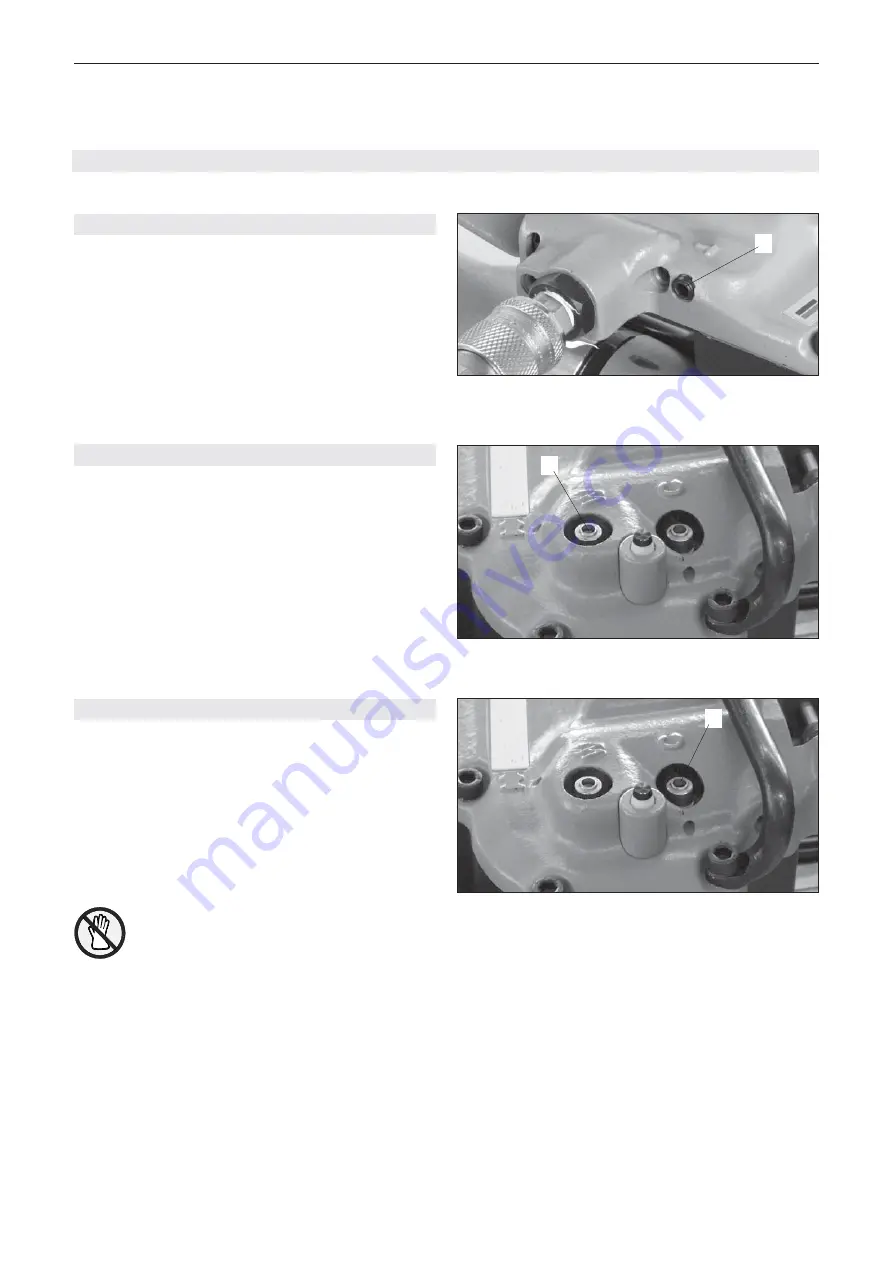

7.1 ADJUSTING TENSIONING FORCE

– Set air pressure at pressure reducing valve of

maintenance unit to 5.7–6.2 bar.

– With a hex screwdriver adjust adjustment screw

(11/1) of air motor, so that the motor stops when the

required tension is reached. Turning the screw

clockwise the tension is reduced, turning counter-

clockwise tension is increased.

7.2 ADJUSTING WELDING TIME

– Remove the cap over the setting screw (12/1).

– The welding time can be in

fi

nitely adjusted with a

screwdriver (no 0), depending on strap quality and

dimension.

– By turning the screw carefully clockwise (

1

/

8

-

1

/

4

), the

welding time will be longer, by turning counter-clock-

wise it will be shorter.

– Adjust welding time according chapter 6.2, Fig. 10/2.

– Replace the cap over the setting screw.

7

PREVENTIVE AND CORRECTIVE MAINTENANCE

Fig. 12

1

Fig. 13

1

Fig. 11

1

7.3 ADJUSTING COOLING TIME

– Remove the cap over the setting screw (13/1).

– The cooling time can be in

fi

nitely adjusted with a

screwdriver (no 0), depending on strap quality and

dimension.

– By turning the screw carefully clockwise (

1

/

8

-

1

/

4

), the

cooling time will be longer, by turning counter-clock-

wise it will be shorter.

– Insert strap and perform a welding.

A properly

adjusted cool time should allow the strap joint to

cool for approximately 3 to 5 seconds.

Cool time which is too short may lead to

strap

joint

seperation.

– Replace the cap over the setting screw.