Preparation

−5−

Recommended motor

Application

2LS

type

4LS

type

K

series

MSD

series

Constant

speed

Motor leads

type

2RK6GN-A

4RK25GN-A

2RK6GN-C

4RK25GN-C

Position holding

2RK6GN-AM

4RK25GN-AM

2RK6GN-CM

4RK25GN-CM

─

4IK25GN-SM

Speed change

MSD206-411D/U

MSD425-411D/U

MSD206-412D/U

MSD425-412D/U

*

This table lists representative motors that can be combined. In addition to the above,

GN

pinion motors of

o

60 mm (2.36 in.) and

o

80 mm (3.15 in.) can also be combined with the

2LS

type and

4LS

type, respectively.

*

When the rack is used in a vertical direction, the speed control cannot be performed in driving to the downward

direction. Use it at full speed.

Note

•

When performing constrained operation using a torque motor, do not cause the motor to

stop upon contacting a hard stop. Doing so will not only generate excessive torque, but

also transmit inertial impact force to the linear head, which will significantly reduce the

service life of the linear head.

•

When performing push-motion operation, use a spring or other buffer material on the

pressing section. If push-motion operation is performed without using any buffer material,

the internal gear may be damaged due to rotor inertia.

Spring

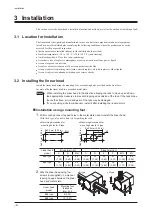

2.4 Names and functions of parts

Mounting foot

Mounting holes

(for mounting on

the front face)

Rack

Rack bushing

A guide that holds the rack in place.

Tapped holes used to install a load

(two locations)

Mounting groove for the dog or shield plate

(sold separately)

Mounting screw for the limit switch

or photomicrosensor

(sold separately)

Mounting holes

Rack case