5

Note

•

Do not forcibly assemble the motor and gearhead. Also, prevent

metal objects or foreign substances from entering in the

gearhead. The pinion of the motor output shaft or gear may be

damaged, resulting in noise or shorter service life.

•

Do not allow dust to attach to the pilot sections of the motor and

gearhead. Also, assemble the motor and gearhead carefully by

not pinching the O-ring at the motor pilot section. If the O-ring is

crushed or severed, grease may leak from the gearhead.

Installing a load

If a large impact occurs at instantaneous stop or a large radial load is applied,

secure a stepped load shaft.

Note

•

Apply grease (molybdenum disulfide grease, etc.) on the surface

of the load shaft and inner walls of the hollow output shaft to

prevent seizure.

•

When installing a load, do not damage the output shaft or

bearing. Forcibly inserting the load by driving it with a hammer

may damage the bearing. Do not apply any excessive force to the

output shaft.

•

Do not modify or machine the output shaft. This may damage

the bearing, resulting in damage to the motor and gearhead.

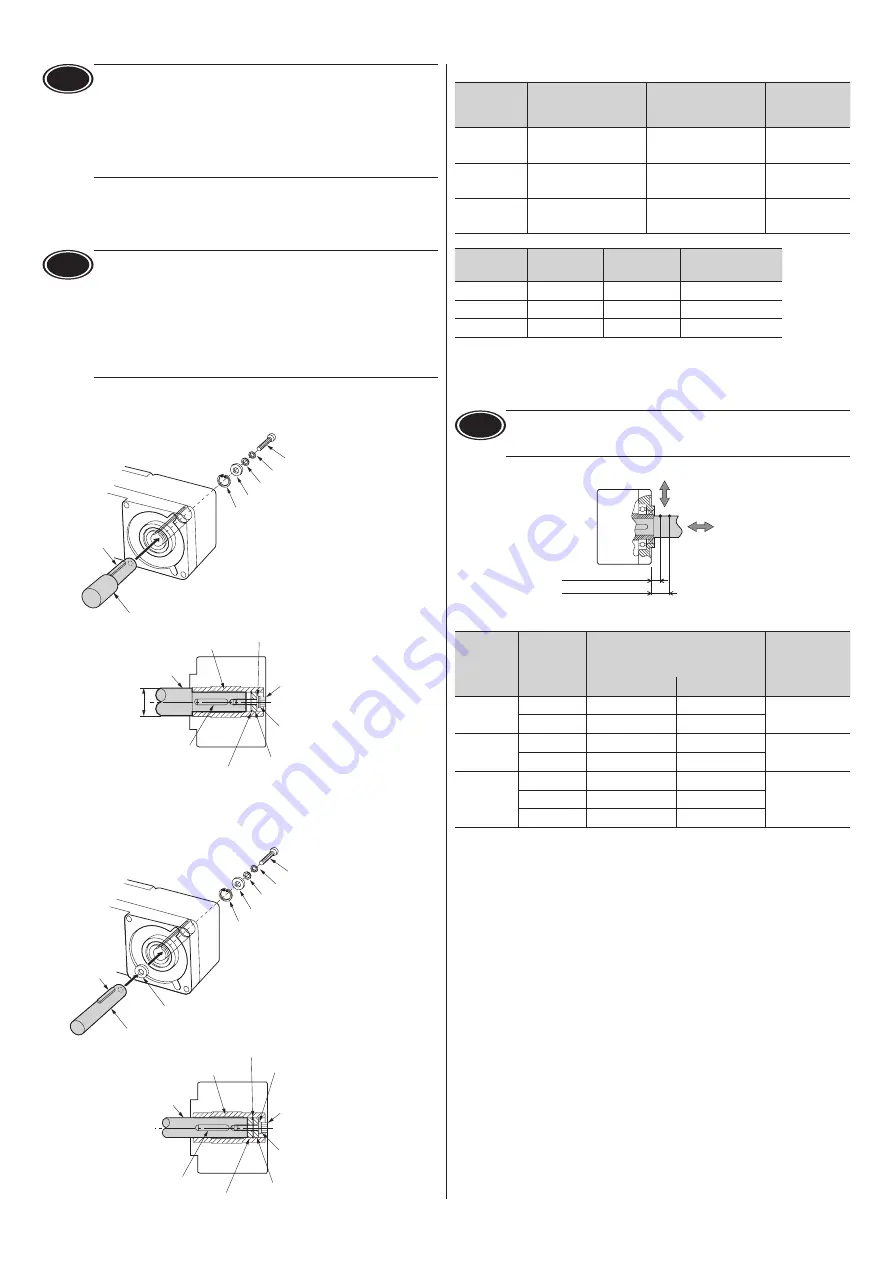

z

Stepped load shaft

Secure the retaining ring to the load shaft by tightening the hexagonal socket

head screw over a spacer, plain washer and spring washer.

Plain washer

Spacer

Retaining ring

Stepped load shaft

Parallel key

Spring washer

Hexagonal socket head screw

Retaining ring

Hollow output shaft

Hexagonal socket

head screw

Spring washer

Plain washer

Spacer

Parallel key

Load shaft

ØD

z

Non-stepped load shaft

Install a spacer on the load shaft side and secure the retaining ring to the load

shaft by tightening the hexagonal socket head screw over a spacer, flat washer

and spring washer.

Plain washer

Spacer

Retaining ring

Spring washer

Hexagonal socket head screw

Spacer

Stepped load shaft

Parallel key

Spacer

Retaining ring

Hollow output shaft

Hexagonalsocket

head screw

Spring washer

Plain washer

Spacer

Parallel key

Load shaft

Recommended load shaft installation dimensions [Unit: mm (in.)]

Output

power

Inner diameter of

hollow shaft (H8)

Recommended

diameter of load shaft

(h7)

Nominal

diameter of

retaining ring

30 W

Ø12

+0.027

0

(Ø0.4724

+0.0011

0

)

Ø12

0

-0.018

(Ø0.4724

0

-0.0007

)

Ø12 (Ø0.47)

60 W

Ø15

+0.027

0

(Ø0.5906

+0.0011

0

)

Ø15

0

-0.018

(Ø0.5906

0

-0.0007

)

Ø15 (Ø0.59)

120 W

Ø20

+0.033

0

(Ø0.7874)

+0.0013

0

Ø20

0

-0.021

(Ø0.7874)

0

-0.0008

Ø20 (Ø0.79)

Output

power

Applicable

screw

Spacer

thickness

Outer diameter of

stepped shaft (ØD)

30 W

M4

3 (0.12)

20 (0.79)

60 W

M5

4 (0.16)

25 (0.98)

120 W

M6

5 (0.20)

30 (1.18)

Permissible radial load and permissible axial load

Make sure a radial load and axial load applied to the output shaft will not exceed

the permissible values shown in the table below.

Note

Failure due to fatigue may occur when the bearings and output

shaft are subject to repeated loading by a radial or axial load that is

in excess of the permissible limit.

10 mm (0.39 in.)

20 mm (0.79 in.)

Distance from mounting surface

Axial load

Radial load

Output

power

Gear ratio

Permissible radial load [N (lb.)]

Distance from gearhead mounting

surface

Permissible

axial load

[N (lb.)]

10 mm (0.39 in.) 20 mm (0.79 in.)

30 W

5

,

10

450 (101)

370 (83)

200 (45)

15

to

200

500 (112)

400 (90)

60 W

5

,

10

800 (180)

660 (148)

400 (90)

15

to

200

1200 (270)

1000 (220)

120 W

5

,

10

900 (200)

770 (173)

500 (112)

15

,

20

1300 (290)

1110 (240)

30

to

200

1500 (330)

1280 (280)