7

Grounding

Ground using the Protective Earth Terminals of the motor and driver and the

ground terminal of the connection cable. Check the operating manual of the

driver for how to ground.

Note

Be sure to ground the motor and driver. Failure to do so may result

in electric shock or damage to the product. Static electricity may

cause damage to the product if the Protective Earth Terminals are

not grounded.

Inspection and maintenance

Inspection

It is recommended that periodic inspections would be conducted for the items

listed below after each operation of the motor.

If an abnormal condition is noted, discontinue any use and contact your nearest

Oriental Motor sales office.

Note

Do not conduct the insulation resistance measurement or dielectric

strength test with the motor and driver connected. Conducting

the insulation resistance measurement or dielectric strength test

with the motor and driver connected may result in damage to the

product.

z

Inspection item

•

Check if any of the mounting screws of the motor is loose.

•

Check if the bearing part (ball bearings) of the motor generates unusual

noises.

•

Check if the bearing part (ball bearings) or gear meshing part of the gearhead

generates unusual noises.

•

Check if the output shaft and a load shaft are out of alignment.

•

Check if a damage or stress is applied on the cable or the connection part

between the cable and driver is loose.

Warranty

Check on the Oriental Motor Website for the product warranty.

Disposal

Dispose the product correctly in accordance with laws and regulations, or

instructions of local governments.

Specifications

Check on the Oriental Motor Website for the product specifications.

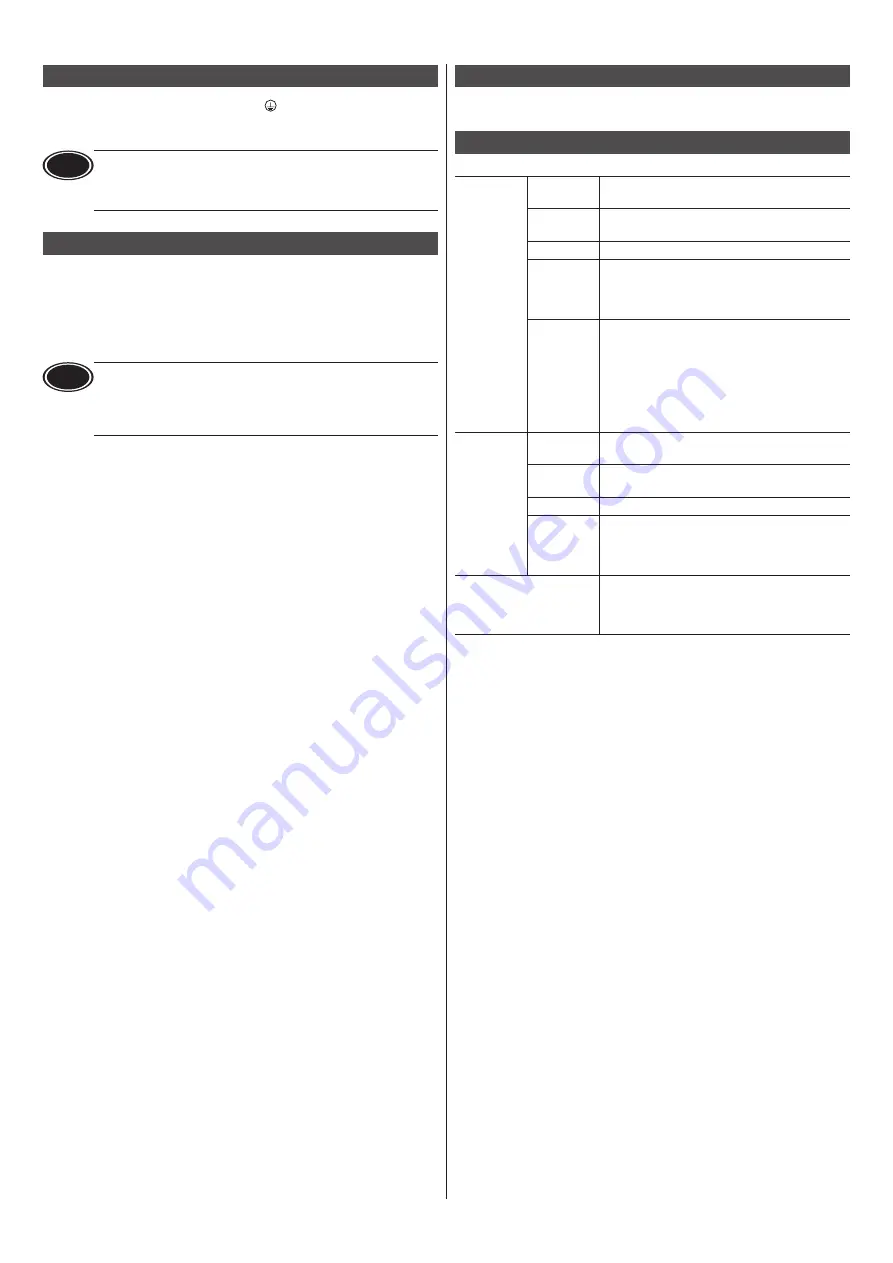

General specifications

Operating

environment

Ambient

temperature 0 to +40 °C [+32 to +104 °F] (non-freezing)

Ambient

humidity

85% or less (non-condensing)

Altitude

Up to 1000 m (3300 ft.) above sea level

Surrounding

atmosphere

No corrosive gas, dust.

Cannot be used in radioactive materials,

magnetic field, vacuum or other special

environment.

Vibration

Not subject to continuous vibrations or excessive

impact.

In conformance with JIS C 60068-2-6 "Sine-wave

vibration test method"

Frequency range: 10 to 55 Hz

Pulsating amplitude: 0.15 mm

Sweep direction: 3 directions (X, Y, Z)

Number of sweeps: 20 times

Storage

environment

Shipping

environment

Ambient

temperature −20 to +70 °C [−4 to +158 °F] (non-freezing)

Ambient

humidity

85% or less (non-condensing)

Altitude

Up to 3000 m (10000 ft.) above sea level

Surrounding

atmosphere

No corrosive gas, dust, water or oil.

Cannot be used in radioactive materials,

magnetic field, vacuum or other special

environment.

Degree of protection

IP65

(When the connection cable is installed to the

motor. Excluding the part of the connectors for

driver connection.)