2

y

Do not use the product beyond its specifications.

This may cause injury or damage to equipment.

y

Keep your fingers and objects out of the openings in the product.

Failure to do so may result in fire or injury.

y

Do not touch the product while operating or immediately after

stopping.

This may cause a skin burn(s).

y

Do not forcibly bend or pull the cable that was connected to the

driver.

Doing so may cause damage.

y

Keep the area around the product free of combustible materials.

Failure to do so may result in fire or a skin burn(s).

y

Leave nothing around the product that would obstruct ventilation.

Failure to do so may result in damage to equipment.

y

Do not touch the rotating part (output shaft) while operating the

motor.

Doing so may result in injury.

y

Use a motor and driver only in the specified combination.

Failure to do so may result in fire.

y

Provide an emergency stop device or emergency stop circuit

external to the equipment so that the entire equipment will

operate safely in the event of a system failure or malfunction.

Failure to do so may result in injury.

y

Before supplying power to the driver, turn all input signals to the

driver to OFF.

Failure to do so may result in injury or damage to equipment.

y

Before moving the motor directly with the hands, confirm that the

AWO input turns ON.

Failure to do so may result in injury.

y

When an abnormal condition has occurred, immediately stop

operation and turn off the driver power.

Failure to do so may result in fire or injury.

y

Dispose the product correctly in accordance with laws and

regulations, or instructions of local governments.

Precautions for use

•

When conducting the insulation resistance measurement and

the dielectric strength test, be sure to separate the connection

between the motor and the driver.

Conducting the insulation resistance test or dielectric strength test with the

motor and driver connected may result in damage to the product.

•

Regeneration

When a large load inertia is operated at a high speed, the power supply

voltage may increase by the regenerated energy generated, causing an

alarm of overvoltage to generate. This may result in damage to the driver, so

reconsider the operating condition so as not to generate the regenerative

voltage.

General specifications

Operation

environment

Ambient

temperature

0 to +50 °C (+32 to +122 °F)

(non-freezing)

Humidity

85% or less (non-condensing)

Altitude

Up to 1000 m (3300 ft.) above sea level

Surrounding

atmosphere

No corrosive gas, dust, water or oil

Storage

environment,

Shipping

environment

Ambient

temperature

−25 to +70 °C (−13 to +158 °F)

(non-freezing)

Humidity

85% or less (non-condensing)

Altitude

Up to 3000 m (10000 ft.) above sea level

Surrounding

atmosphere

No corrosive gas, dust, water or oil

Regulations and standards

CE Marking

z

Low Voltage Directive

Although this product is exempt from the Low Voltage Directive since

the input power supply voltage is 24 VDC, perform the installation and

connection as follows.

y

This product is designed and manufactured to be incorporated in

equipment. Be sure to install the product in an enclosure.

y

For the driver power supply, use a DC power supply with reinforced

insulation on its primary and secondary sides.

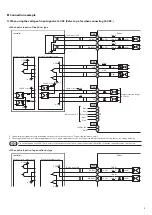

z

EMC Directive

This product is conducted EMC testing under the conditions specified in

"Example of motor and driver installation and wiring" on p.10. The conformance

of your mechanical equipment with the EMC Directive will vary depending

on such factors as the configuration, wiring, and layout for other control

system devices and electrical parts used with this product. It therefore must

be verified through conducting EMC measures in a state where all parts

including this product have been installed in the equipment.

Applicable Standards

EMI

EN 61000-6-4, EN 55011 group 1 class A

EMS

EN 61000-6-2

This equipment is not intended for use in residential

environments nor for use on a low-voltage public network

supplied in residential premises, and it may not provide

adequate protection to radio reception interference in

such environments.

Republic of Korea, Radio Waves Act

This product is affixed the KC Mark under the Republic of Korea, Radio Waves

Act.

RoHS Directive

The products do not contain the substances exceeding the restriction values

of RoHS Directive (2011/65/EU).

Preparation

Checking the product

Verify that the items listed below are included. Report any missing or

damaged items to the branch or sales office from which you purchased the

product.

y

Driver ................................................................. 1 unit

y

OPERATING MANUAL .................................. 1 copy (this document)

y

Connector housing/contact ..................... 1 set

(Packed in a bag; see table below.)

Application

Housing (Molex)

Contact (Molex)

For power supply (CN1)

1 pc. 51103-0200 (2-poles)

19 pcs.

50351-8100

For motor (CN2)

1 pc. 51103-0500 (5-poles)

For I/O signals (CN3)

1 pc. 51103-1200 (12-poles)

When removing the driver from the ESD protection bag, make sure

your hands are not charged with static electricity. This is to prevent

damage to the driver due to static electricity.