6

z

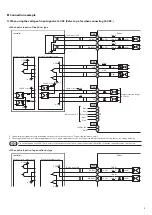

When using the voltage of input signals at 24 VDC

•

When pulse input is of open-collector type

Driver

1.5 to 2.2 kΩ

0.5 W or more

1.5 to 2.2 kΩ

0.5 W or more

1.5 to 2.2 kΩ

0.5 W or more

0 V

0 V

PLS (CW)

CN3

2

1

100 Ω

Twisted pair cable

Controller

100 Ω

100 Ω

100 Ω

2.2 kΩ

2.2 kΩ

2.2 kΩ

2.2 kΩ

1.5 to 2.2 kΩ

0.5 W or more

DIR (CCW)

4

3

24 VDC

R2

R2

R1

R1

R1

R1

24 VDC

R0

0 V

0 V

0 V

GND

24 VDC±10%

AWO

ALM

CN3

CN3

CN1

Motor lead wire

*1

5

4

3

2

1

10

9

R0

TIM

12

11

6

5

-

+

CN2

Current sink output circuit

Current source output circuit

470 Ω

1 kΩ

CS

8

7

470 Ω

1 kΩ

0 V

30 VDC or less

30 VDC or less

Output saturated

voltage

0.5 V max.

24 VDC

24 VDC

*2

1.5 to 2.2 kΩ

0.5 W or more

1.5 to 2.2 kΩ

0.5 W or more

10 mA or less

Red

Blue

Green

Black

Orange*2

*1 Connector pin assignments vary depending on the motor. For details, refer to "Connecting the motor" on p.4.

*2 This orange lead wire is for 5-phase stepping motor. For 2-phase stepping motor, do not connect anything to the pin No.3 since there is no orange lead wire.

y

The input voltage specification for the CW input and CCW input is 5 VDC. If the voltage exceeding 5 VDC is applied, connect an external resistor R1 so

that the input current becomes 7 to 20 mA.

Example) When the 24 VDC is connected: R1 = 1.5 to 2.2 kΩ, 0.5 W or more

y

The input voltage specification for the AWO input and CS input is 5 VDC. If the voltage exceeding 5 VDC is applied, connect an external resistor R2 so

that the input current becomes 5 to 15 mA.

Example) When the 24 VDC is connected: R2 = 1.5 to 2.2 kΩ, 0.5 W or more

y

Use output signals at 30 VDC, 10 mA or less. If the current exceeds 10 mA, connect an external resistor R0 so that the current becomes 10 mA or less.