8

Explanation of I/O signals

z

Input signals

The signal input state represents "ON: Carrying current" or "OFF: Not carrying

current" state of the internal photocoupler.

The interval for switching the motor direction represents the response time of

the circuit. Set this interval to an appropriate time after which the motor will

respond.

•

PLS (CW) input, DIR (CCW) input

Set a desired pulse input mode of the driver according to the pulse output

mode of the controller used with the driver.

Maximum input pulse frequency (duty cycle is 50%)

y

When the controller is of line driver type: 1 MHz

y

When the controller is of open-collector type: 250 kHz

1-pulse input mode

When the PLS input is turned from OFF to ON while the DIR input is ON, the

motor will rotate by one step in CW direction.

When the PLS input is turned from OFF to ON while the DIR input is OFF, the

motor will rotate by one step in CCW direction.

2-pulse input mode

When the CW input is turned from OFF to ON, the motor will rotate by one

step in CW direction.

When the CCW input is turned from OFF to ON, the motor will rotate by one

step in CCW direction.

y

When the motor is at standstill, be sure to keep the photocoupler in

OFF state.

y

Do not input the CW pulse and CCW pulse simultaneously. If the

other pulse is input while one of the pulse is ON, the motor cannot

operate normally.

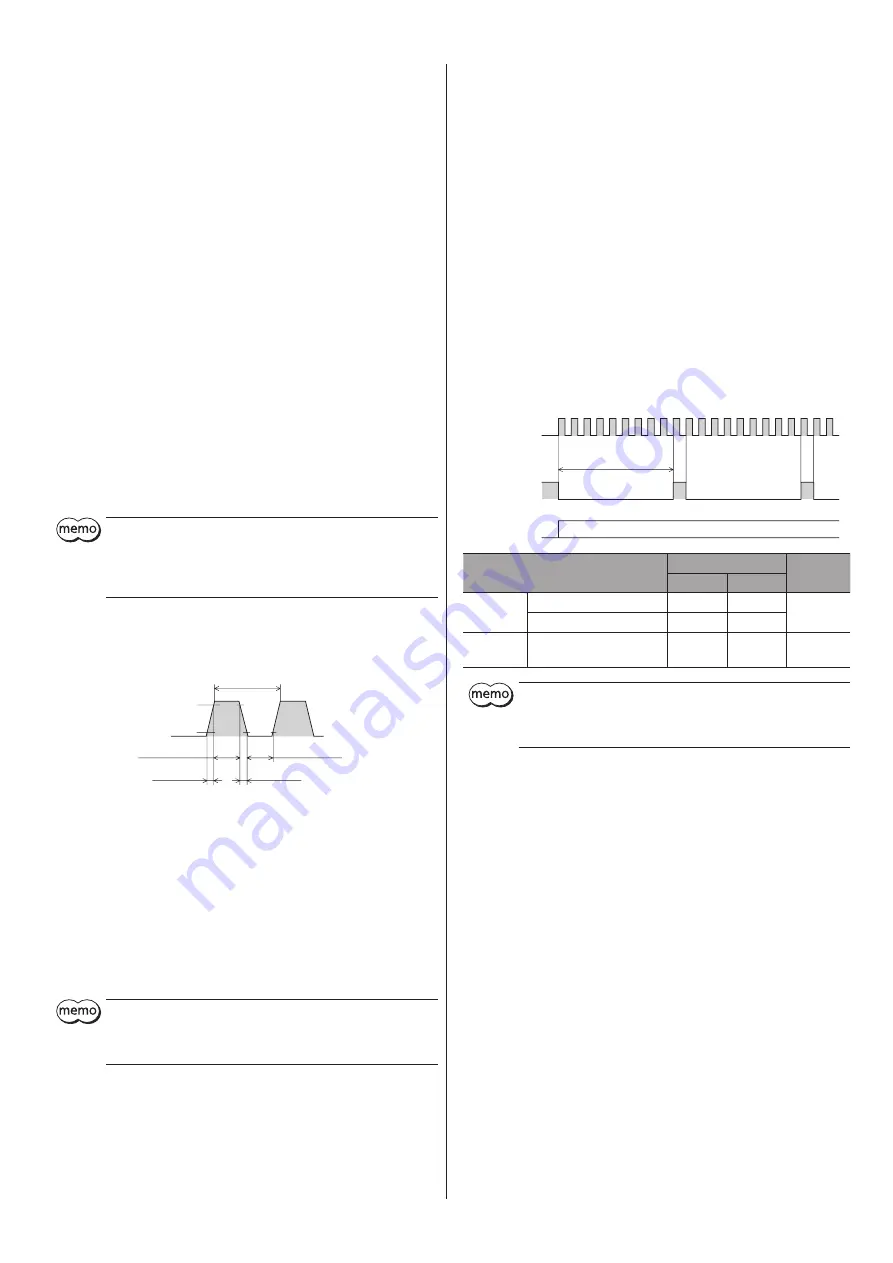

Pulse signal

Pulses with sharp rising and falling edges should be input as shown in the

figure below. The figure shows the voltage levels of pulse signals.

90%

10%

0.4 µs or more

0.4 µs or more

1 µs or more

2 µs or less

2 µs or less

ON

OFF

•

AWO (all windings off) input

When the AWO input is turned ON, the motor current will be cut off and the

motor will lose its holding torque. The motor output shaft can be turned

manually.

When the AWO input is turned OFF, current will be supplied and the holding

torque will be restored.

•

CS (step angle switching) input

When the CS input is turned ON, the motor rotates at a basic step angle.

When the CS input is turned OFF, the motor rotates at the step angle set by

the driver switch.

y

Do not change the CS input while operating. The motor may lose its

synchronism, causing position deviation or standstill of the motor.

y

When changing the step angle using the CS input, do so while the

TIM output is ON.

z

Output signals

The driver outputs signals are photocoupler/open-collector output. The

signal output state represents "ON: Carrying current" or "OFF: Not carrying

current" state of the internal photocoupler.

•

ALM (alarm) output

The ALM output is normally closed. When an alarm generates, the ALM

output will turn OFF and the motor current will be cut off.

At the same time, the PWR/ALM LED of the driver will blink in red.

•

TIM (timing) output

Every time the motor output shaft rotates by 7.2° (3.6° for high-resolution

type), the motor excitation state becomes the initial setting state (step 0), and

the TIM output turns ON. If an AND circuit is configured with signals of the

home sensor and TIM output when the home position in the equipment is

detected, the tolerance for the motor stop positions in a detection range of

the home sensor can be reduced and the further accurate home position can

be detected.

Example of the TIM output when the step angle is 0.72

°

(resolution

500 P/R)

Pulse input

Motor output shaft

rotates by 7.2º.

1 2 3

• • •

1

0

20

ON

OFF

TIM output

ON

OFF

Motor operation

Motor type

Number of divisions

TIM output

1

10

Standard

Base step angle 1.8°/step

1.8°

0.18°

every 7.2°

Base step angle 0.72°/step

0.72°

0.072°

High-

resolution

Base step angle 0.36°/step

0.36°

0.036°

every 3.6°

y

When using the TIM output, keep the input pulse frequency to be

500 Hz or less.

y

When using the TIM output, set the pulse or step angle so that the

motor output shaft stops at an integral multiple of 7.2°.