7

Removing/Installing the gearhead

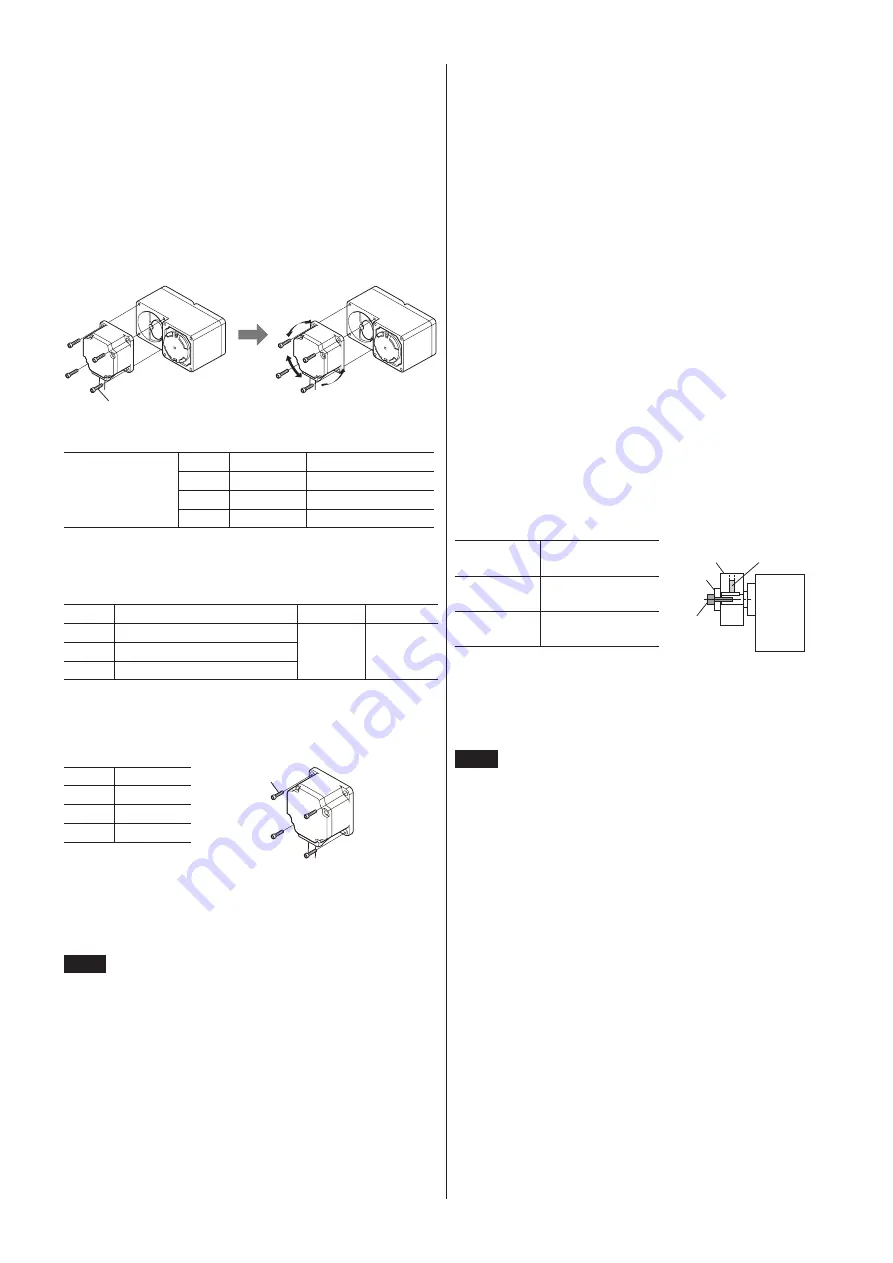

To replace the gearhead or change the cable outlet direction, remove the

screws assembling the gearhead. The gearhead can be removed and the motor

cable position changed to one of three 90° directions. Note that the motor

cable cannot be positioned in the direction where the cable faces the gearhead

output shaft.

1. Remove the hexagonal socket head screws (4 pcs) attaching the motor and

gearhead and detach the motor from the gearhead.

2. Using the pilot sections of the motor and gearhead as guides, install the

motor to the gearhead and tighten the hexagonal socket head screws.

Install the motor carefully to prevent the pinion of the motor output shaft

from contacting the casing or gear of the gearhead.

Hexagonal socket

head screw

Change the cable

position to a desired

90° direction.

Assembly screws

Model

Screw size

Tightening torque

BLE23

M4

1.8 N·m (15.9 lb-in)

BLE46

M6

6.4 N·m (56 lb-in)

BLE512

M8

15.5 N·m (137 lb-in)

Installing the round shaft type

Install the motor to a mounting plate of the following size or larger, so that

the motor case temperature will not exceed 90 °C (194 °F).

Model

Size of mounting plate

Thickness

Material

BLE23

115×115 mm (4.53×4.53 in.)

*

5 mm

(0.20 in.)

Aluminum

alloy

BLE46

135×135 mm (5.31×5.31 in.)

BLE512

165×165 mm (6.50×6.50 in.)

∗

*

Electromagnetic brake type: 135×135 mm (5.31×5.31 in.)

Secure the motor using the hexagonal socket head screws (not supplied)

through the four mounting holes. Tighten the nuts until no gaps remain

between the motor and mounting plate.

Model

Screw size

Screw

BLE23

M4

BLE46

M6

BLE512

M8

Installing a load to the combination type • parallel

gearhead or round shaft type

When installing a load on the motor, gearhead, align the center of the motor

output shaft (gearhead output shaft) with the center of the load shaft.

Note

•

When coupling the motor, gearhead with a load, pay

attention to centering, belt tension, parallelism of pulleys,

etc. Also, firmly secure the tightening screws of the coupling

or pulleys.

•

When installing a load, do not damage the motor output

shaft (gearhead output shaft) or bearing. Forcing in the load

by driving it with a hammer, etc., may break the bearing. Do

not apply any excessive force to the output shaft.

•

Do not modify or machine the motor, gearhead output shaft.

The bearing may be damaged or motor, gearhead may

break.

•

z

Output shaft shape

Combination type • parallel shaft gearhead

A key slot is provided on the output shaft of each combination type parallel

shaft gearhead. Form a key slot on the load side and secure the load using the

supplied parallel key.

Round shaft type

A flat section is provided on the motor output shaft of each round shaft type.

Apply a double-point screw, etc., at the flat section to firmly secure the load

and prevent it from spinning.

•

z

How to install a load

Using a coupling

Align the centerline of the motor, gearhead output shaft with the centerline of

the load shaft.

Using a belt drive

Adjust the motor, gearhead output shaft to lie parallel with the load shaft and

form right angles between the output shaft/load shaft and the line connecting

the centers of both pulleys.

Using a gear drive

Adjust the motor, gearhead output shaft to lie parallel with the gear shaft and

allow the output shaft to mesh correctly with the centers of the gear teeth.

When using the output shaft end tapped hole of a gearhead

Use a tapped hole provided at the end of the output shaft as an auxiliary

means for preventing the transfer mechanism from disengaging.

(The output shaft end tapped hole is not provided for the

GFS2G

type.)

Gearhead

model name

Output shaft end

tapped hole

Fixed screw

Screw

Spacer

Transmission

parts

GFS4G

M5, Effective depth

10 mm (0.39 in.)

GFS5G

M6, Effective depth

12 mm (0.47 in.)

Installing a load to the combination type • hollow shaft

flat gearhead

If the motor is subject to a strong impact upon instantaneous stop or receives

a large radial load, use a stepped load shaft.

Note

•

Apply grease (molybdenum disulfide grease, etc.) on the

surface of the load shaft and inner walls of the hollow output

shaft to prevent seizure.

•

When installing a load, do not damage the hollow output

shaft or bearing of the gearhead. Forcing in the load by

driving it with a hammer, etc. may break the bearing. Do not

apply any excessive force to the hollow output shaft.

•

Do not modify or machine the hollow output shaft of the

gearhead. Doing so may damage the bearings and destroy

the gearhead.