2

Preparation

Checking the product

Upon opening the package, verify that the items listed below are

included. Report any missing or damaged items to the branch or

sales office from which you purchased the product.

•

Fan .............................................................................. 1 pc.

•

Power cable ................................................................ 1 pc.

•

Air Control Louver ..................................................... 1 pc.

•

Set of mounting screws for fan mounting .................. 1 set

(M5 Hexagonal socket head screws with captive washer,

Hexagonal nuts with flange 4 pcs. each)

•

Mounting screws for Air Control Louver (M5 Cross-recessed pan

head screws with captive washer) .............................. 4 pcs.

•

Operating manual (this manual) ................................. 1 copy

Checking the model name

To verify that the unit you’ve purchased is the correct one, check the

model number shown on the identification plate.

MBS18-BH

,

MBS18-BWH

,

MBS18-DH

,

MBS18-DWH

,

MBS18-TH

,

MBS18-TWH

,

MBS20-BH

,

MBS20-BWH

,

MBS20-DH

,

MBS20-DWH

,

MBS20-TH

,

MBS20-TWH

Installation

Location for installation

The fan is designed and manufactured for installation in equipment.

Install it in a well-ventilated location that provides easy access for

inspection. The location must also satisfy the following conditions:

•

Inside an enclosure that is installed indoors

•

Operating ambient temperature −10 to +60 °C (+14 to +140 °F)

(non-freezing)

•

Operating ambient humidity 85% or less (non-condensing)

•

Area that is free of explosive atmosphere or toxic gas (such as

sulfuric gas) or liquid

•

Area not exposed to direct sun

•

Area free of excessive amount of dust, iron particles or the like

•

Area not subject to splashing water (rains, water droplets), oil (oil

droplets) or other liquids

•

Area not subject to continuous vibration or excessive shocks

•

Area free of radioactive materials, magnetic fields or vacuum

•

Area free of excessive electromagnetic noise (from welders, power

machinery, etc.)

When using near a switching circuit or high-frequency power

supply, the induced current may flow inside the fan due to

electromagnetic noise (conductive noise, radiative noise). If the

induced current flows, the electric corrosion is caused in the

bearings of the fan. As a result, it may generate the noise or shorten

the service life of the products. Use the fan in the environment that

the electromagnetic noise does not cause.

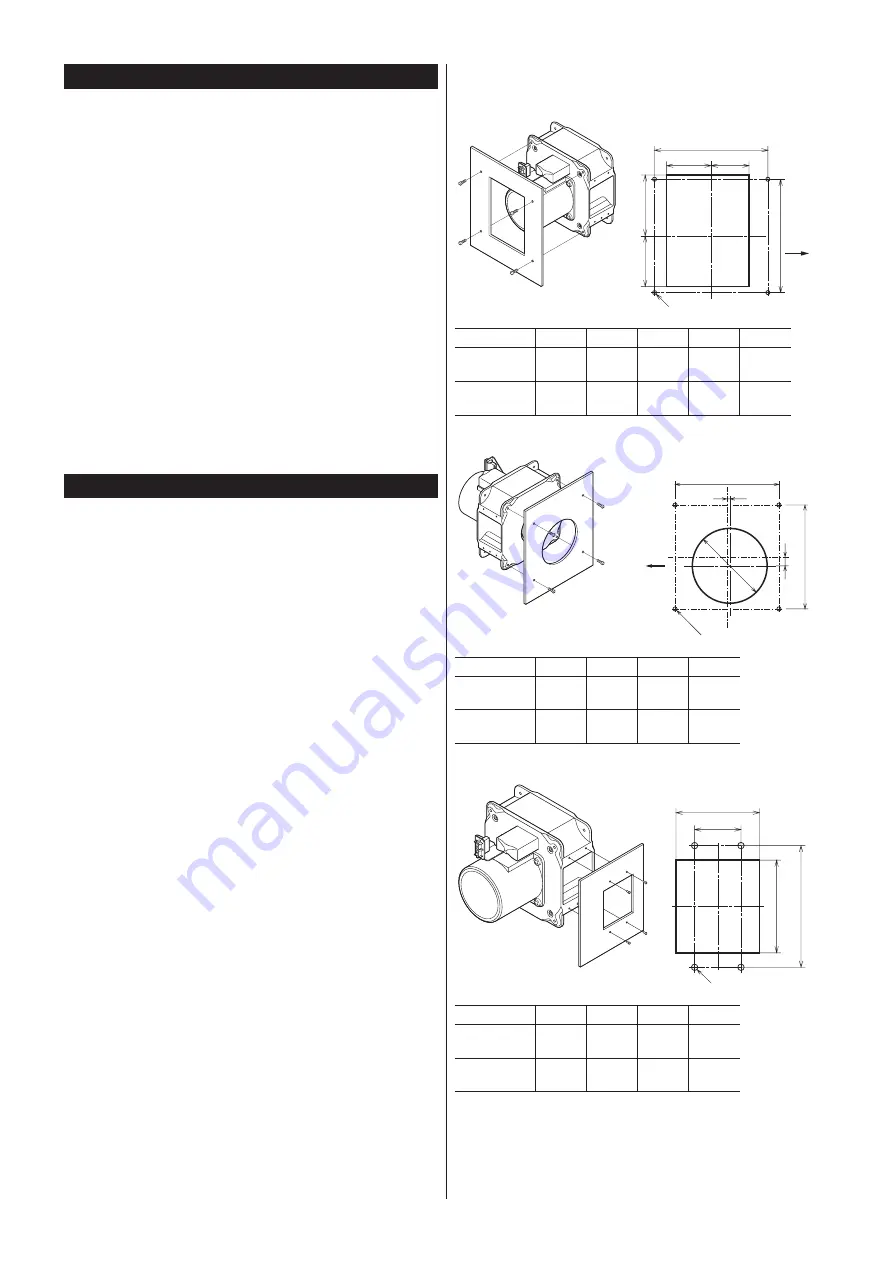

How to install the fan

Install the fan onto an appropriate flat metal plate having excellent

vibration resistance and heat conductivity. Consider the weight of the

fan and install the fan in a location where sufficient strength can be

ensured.

Drill mounting holes in your equipment and affix the fan using the

supplied screws and the four mounting holes provided in the fan

casing.

Tightening torque: 1.2 N·m

z

Installing method and installation dimensions

Motor side installation

Installation dimensions

[Unit: mm (in.)]

L2

L1

L4

4×Ø5.5 (Ø0.217)

L1

Outflow

L5

L3

Model

L1

L2

L3

L4

L5

MBS18-

152.7

(6.012)

60

(2.36)

51

(2.01)

82

(3.23)

68

(2.68)

MBS20-

166.9

(6.571)

59

(2.32)

52

(2.05)

92

(3.62)

68

(2.68)

Suction side installation

Installation dimensions

[Unit: mm (in.)]

L2

L1

L4

L1

L3

Outflow

4×Ø5.5 (Ø0.217)

Model

L1

L2

L3

L4

MBS18-

152.7

(6.012)

4

(0.17)

13

(0.52)

107

(4.21)

MBS20-

166.9

(6.571)

3.5

(0.14)

12.5

(0.49)

122

(4.8)

Exhaust side installation

Installation dimensions

[Unit: mm (in.)]

L2

L1

L4

L3

4×Ø5.5 (Ø0.217)

Model

L1

L2

L3

L4

MBS18-

105

(4.13)

72

(2.83)

80

(3.15)

40

(1.57)

MBS20-

120

(4.72)

72

(2.83)

92

(3.62)

40

(1.57)

Select mounting screws that are no more than 8 mm (0.315 in.)

longer than the thickness.