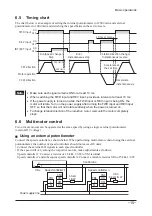

−

7

−

Installation

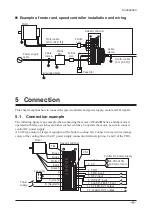

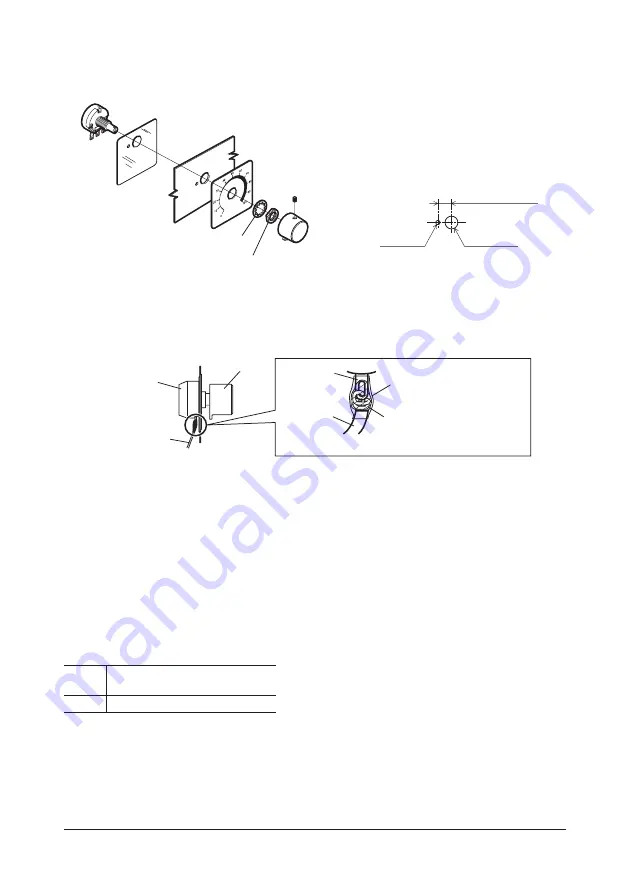

4.3 Installing an external potentiometer (Sold separately)

Install an accessory external potentiometer (sold separately) as shown below.

Nut

Tightening torque:

0.45 N·m (3.9 lb-in)

Setscrew (M4)

Tightening torque:

0.4 N·m (3.5 lb-in)

•

Reference mounting hole

dimensions

[Unit: mm (in.)]

Ø3 (0.12)

7.5±

0.4

(0.3±

0.02

)

Ø10 (0.39)

Dial

Toothed washer

Dial plate

Mounting plate

Insulation sheet

Variable resistor

Soldering the variable resister terminals and the lead wires

Cover a heat-shrinkable tube over the soldered part to insulate.

235 °C (455 °F), less than 5 sec.

Lead wire

Lead wire

Terminal

Heat-shrinkable tube

Dial

Variable resistor

Solder (Pass the lead wire

through the terminal hole and

give it two or three turns.)

4.4 Installing and wiring in compliance with EMC Directive

EMC Directives

The speed controller is designed and manufactured as a component to be installed within another device.

The EMC Directives require that your mechanical equipment in which the speed controller is installed

satisfy the applicable requirements. The installation/wiring methods of the speed controller explained

here represent the basic methods that are effective in helping your mechanical equipment conform to the

EMC Directives. The final level of conformance of your mechanical equipment to the EMC Directives

will vary depending on the control system equipment used with the speed controller, configuration of

electrical parts, wiring, layout, hazard level, and the like. Therefore, you must conduct the EMC tests on

your mechanical equipment to confirm compliance.

Applicable Standards

EMI

EN 55011 Group 1 Class A

EN 61000-6-4

EMS

EN 61000-6-2

Caution: This equipment is not intended for use in residential environments nor for use on a low-voltage

public network supplied in residential premises, and it may not provide adequate protection to

radio reception interference in such environments.

Effective measures must be taken against the EMI that the speed controller may give to adjacent

control-system equipment, as well as the EMS of the speed controller itself, in order to prevent a serious

functional impediment in the machinery. The use of the following installation and wiring methods will

enable the speed controller to be compliant with the EMC Directive.