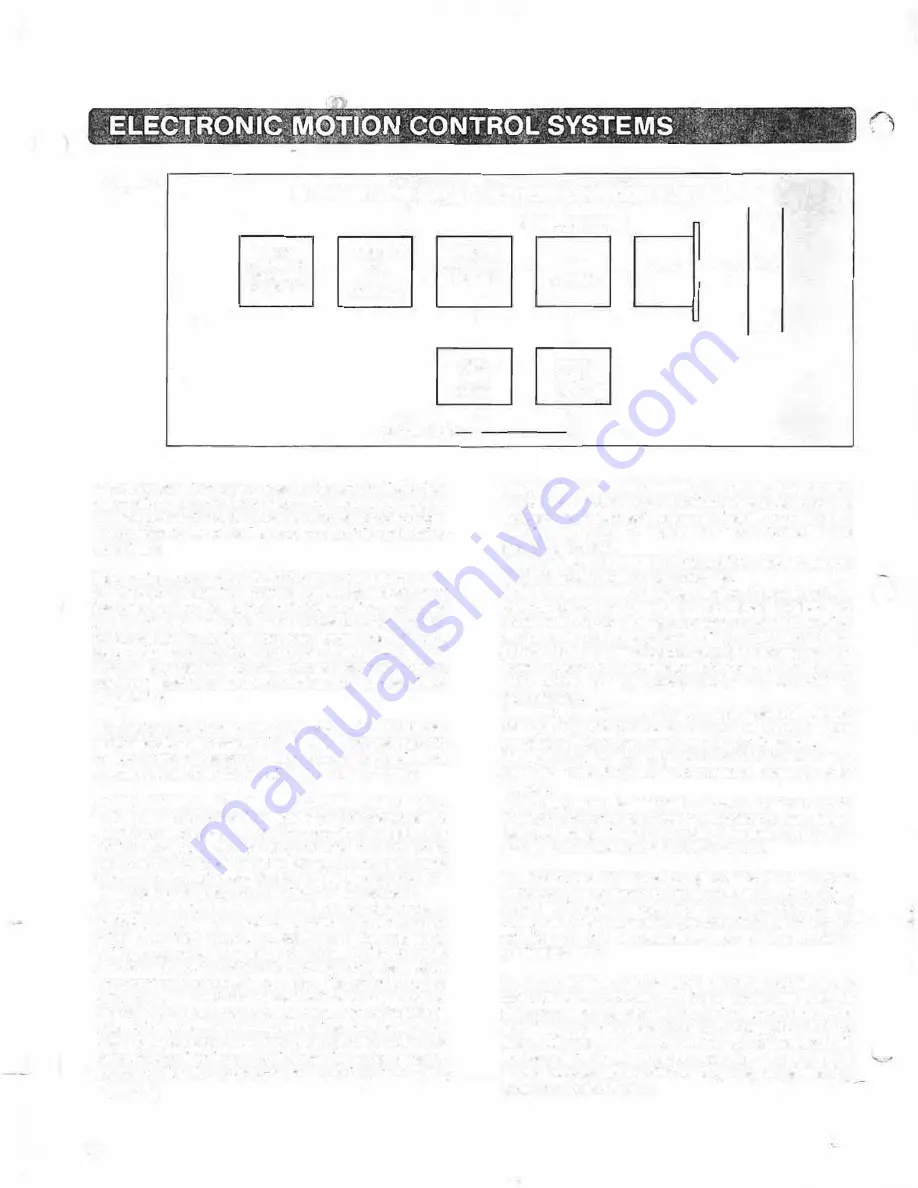

Figure 1

STEP MOTOR BASED MOTION CONTROL SYSTEM

,--

UPD PACKAGE

"Hosr·

INDEXER

LOGIC FDR

POWER

COMPUTER OR

-

OR

-

MOTOR PHASE

-

-

MOTOR

:=J-

LOAD

PROGRAMMABLE

PULSE

CONTROLLER

GENERATOR

I

AC 115VINPUT

With the rapidly increasing need for factory and industrial

automation. manufacturers large and small are turning to

our new genera lion of easy·to-use electronic motion con

trol devices for labor

-

sav

in

g and product1v1ty-enhanc1ng

machinery.

Electronically controlled motion is one of lhe fundamen

tal parts of au

t

oma

t

i

on

.

Increasingly. step motors have

become the favorite method of implementing controlled

molion. One of the many advantages of a step motor·

based system is that 11 can be used "open loop''. Since a

step motor moves a fixed number of degrees for each

input pulse. it can control position and speed without the

additional cost of a leedback device and its associated

electronics.

The basic components or an open loop s1ep motor based

motion system are shown in

Figure

1

.

Sometimes the

various parts of the system are referred lo by d1fferen1

names, bul all of these functions are still included:

HOST COMPUTER OR PROGRAMMABLE CON·

TROLLER:

This is the "intelligent'' part of the system. It

usually controls other parts of lhe machine as well as the

mo11on system 11 can be programmed to respond lo

inputs from switches or other sensors, and may send

information to the 1ncfexer lo control the number of steps,

the acceleralion rate. and slartlng and top s

pe

e

ds

.

INDEXER OR PULSE GENERATOR:

A

pulse generator

is liltle more than an oscillalor. sending pulses to lhe

driver al a l1xed speed Indexers have the additional

ability to count out a number of sle

p

s

�

An indexer may

also control acceleration and de

c

e

l

era

t

i

on

.

As a result

the motor can be made 10 run above its self·starting Ire·

quency (Is). and thus decrease the time 10 make a given

motion. The oulpul from a pulse generator or indexer Is

usually 1n low level (TIL) step and direction signals. The

step signal turns on and off for each step the motor is to

takP., and l�H': direction output 1s held high or low depend

ing on the d1recl1on (CW/E:8Wt-rne motor ,s to move.

(See

Figure

2.)

3

CONTROL

t

LOGIC

POWER

SUPPLY

t

AMPLIFIER

1

-

MOTOR

POWER

SUPPLY

j

LOGIC FOR MOTOR PHASE CONTROL:

This section

translates lhe step and direction signals sent by the

indexer into the correct motor winding On and Off com

bination, in order to make the motor rotate in lhe

desired direc1ion.

LOGIC POWER SUPPLY:

This sec11on supplies the low

level DC power for the logic circuits.

POWER AMPLIFIER:

The signals from the motor phase

.

,

control logic are amplified from low voltage signals to a

useful level that can run a stepping motor. This section

can range in complexity from a simple transistor switch

(L/R drive) with limited speed range, to a complex high

power pulse-width-modulated (ct,opper) drive like the

U PO driver, for high speed torque and outstanding

performance

MOTOR POWER SUPPLY:

The molar

requires

higher

voltage than the control electronics and much more

amperage

.

The motor power supply provides this

MOTOR:

A slepping motor converts the electrical input

from lhe Power Amplifier into rotational movements, or

"s1eps"

LOAD:

The load is whatever the user wants to m

ov

e

.

whether it be powered through a leadscrew, gear liming

bell, or directly dnven by the motor. The load can be tric-

11onal. inertial or a combination of the

tw

o

.

In the pasl each of these separate components had to be

wired togelher or inserted in10:a rack. and valuable lime

was spent in assembling, adj us ling and lrquble-shootmg

them The UPD mo1or/driver package 1sSUPERVEXTA's

solution lo lhis unnecessary use of the systems

engineer's time

.

As shown in

Figure1,

the UPD package combines lhe

motor driver and power supplies into one Unit, and the

driver is pre-set to match lhe motor included in the pack

age. The driver's inputs are optically-isolated lo allow for

easy interface with a wide vanety of controllers. This

leaves only a simple hook-up operalion - and with the

application of step and d1rechon signals. the result is prf

r

cisely controlled motion.