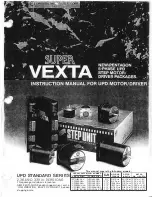

Using the UPD motor driver package, the system

designer has total control over all of the important motion

profile parameters. As shown in Figure

2

,

each step pulse

received by the driver results in a motor movement of one

step. This makes control oL velocity, acceleration, de·

:::eleration and position simply a matter of controlling the

frequency (pulses per iecond) and number of pulses

sent to the driver.

A velocity of exactly one revolution per second can be

obtained from a 0.72 degree motor by sending pulses to

the driver at 500 pulses per second. Acceleration and

deceleration of the motor can be regulated by adjusting

the frequency of the pulses sent to the driver.

Position can also be readily controlled because the

amount or motor movement is equal to the number of

pulses applied to the driver, times the motor step angle.

For example, a 0.72 degree motor can be made to rotate

exactly one revolution by applying 500 pulses to the

driver.

Figure 3shows a typical motion profile. In the time bet

ween T1 and T2, the lrequency

·

of the pulses being sent to

the driver increases, causing the motor to accelerate.

Between T2 and T3, the dnver receives pulses at a fixed

rate, and the motor turns at constant velocity. The pulses

to the driver decrease in frequency between T3 and T4,

until they stop. This causes the motor to slow down and

halt. The amount of shalt rotation in degrees is deter

mined by multiplying the total number of pulses between

T1 and T4 by the number of degrees per step of the

step motor

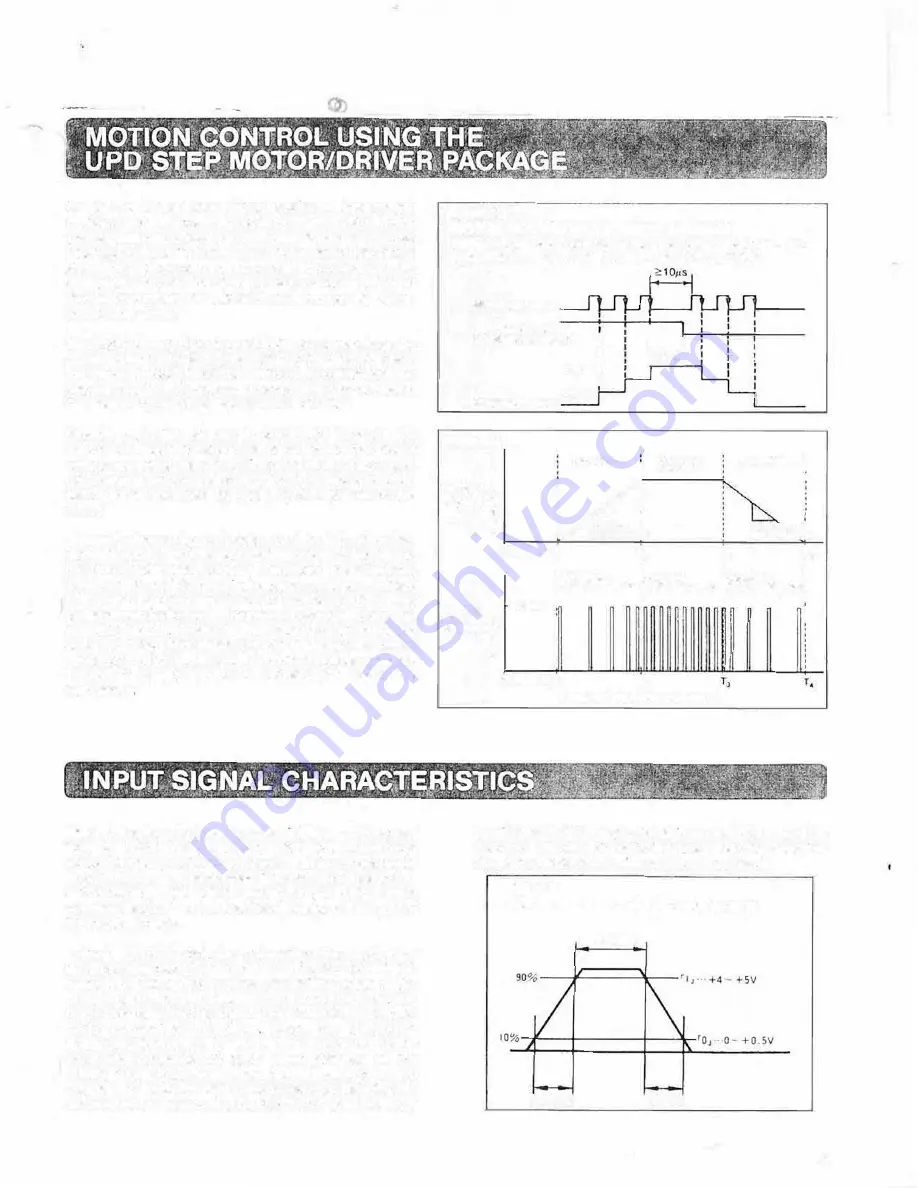

The input pulse waveform is shown in Figure 4.A logical

"ON" or"HIGH" is 4-5 volts, and "LOW" is be1ween 0-0.5

volts. The input pulse should have TIL timing characteris

tics: (i.e., the pulse rise and fafl times must be less than 1

microsecond). The noise liltering in the U PO driver

requires that the input pulses be stable for a minimum of

10 microseconds.

In the "1 PULSE" mode, the motor will rotate one step for

each pulse received at the driver's "PULSE" (STEP) ter

minal. The motor moves when the trailing edge of the

pulse is detected. (See Figure 2.) The direction of rota

tion is controlled by the signal at the "CW/CCW" (DI REC

TION) terminal of the driver When the "CW/CCW"

(DIRECTION) terminal is "HIGH", the motor will rotate

one step clockwise for each pulse received at the

"PULSE" (STEP) terminal. The motor will rotate one step

counter-clockwise for each pulse received at the "PULSE"

terminal when the signal at the "CW/CCW" (DIRECTION)

Figure 2

MOTOR MOVEMENT VS. INPUT SIGNALS

NOTE:

The direction input signal should be changed only while the

step pulse signal is not being sent and is "LOW" or "OFF".

Step Pulse Input

Input for Direction

I

ot Rotation CW/CCW

:

I

I

�10:

I

I

CW

I

_LI

1- 11s,

Motor Movement CCW

Figure 3

MOTOR

l

VELOCITYl;:

PROFILE 0

0

.,

"'

>

ACCEL(RATE

CONSTANT

I

VElOCl'I'(

IALI.

OECElERATE

!

'

St.OPE•,

:

DECELERATION

0 TIME+-�'

:,

;3

;•

I

:

:

:

l1NCREASING

'CONSTANT

'DECREASING

'

l

I PULSE FREOUENCY;PULSE FREOUENCV:PULSE. fR(OUENC'f:

!

I

•

I

+4-SV

'

'

'

PULSE

f

:

TIMING

w

.

I

I

DIAGRAM�

:

:

....

.

:

�

!

l

:

j

OTIME-T,

T,

TYPICAL MOTION PROFILE

terminal is "LOW', or the signal 1s absent. Care must be

taken so lhe step signal 1s inactive when the direction

signal is changed. or missed steps may result.

Figure 4

INPUT PULSE CHARACTERISTICS

5

µ

s MIN

2

µ

s MAX

2,.s MAX

4