( The New-PENTAGON 5-Phase is a� not a

Slllaflrelr)

"'

Accurate and reliable motion control is a fundamental

key to successful automation of any kind. Step motors

have become a vital link 1n lhis automation process with

their ability to change computer-generated input into

mechanical motion They are highly accurate. reliable

and simple to use because or their inherent ability lo

move a certain angle for each input pulse. Step motors

are widely used in appllcallons from medical equipment

to computer peripherals, to oflice copy machines and

factory machine tools.

With their ability lo accurately move and hold loads. stand

ard step motors are a boon to automation. but have two

annoying drawbacks - vibration (resonance) and low

speed

.

Until now, the mosl popular melhods of overcom

ing these elfects were to use either a microstep driver or

some type of damping. Dampers are effective, but space

restraints and the changing of their damping eflects with

temperature and time often preclude their use. Microstep

drivers are a solution to the effects ol resonance and vi

bration at very slow speeds ( <0.25 rpm), but lhe losses in

accuracy and torque, plus the fact that their vibraHon is

the same as a standard step motor al faster speeds, are

all far too costly to ignore.

A newer. more cost-effective method or overcoming the

effects of resonance and vibration is to use a Five-Phase

step motor

.

The Five-Phase stepping motor was originally

patented by the West German company Berger-Lahr.

Oriental Motor recognized the unique attributes of this

product and saw its great potential. After obtaining a

license, Oriental Motor introduced Five-Phase technology

in Japan; it was a hit and "Five-Phase Fever" set in.

5

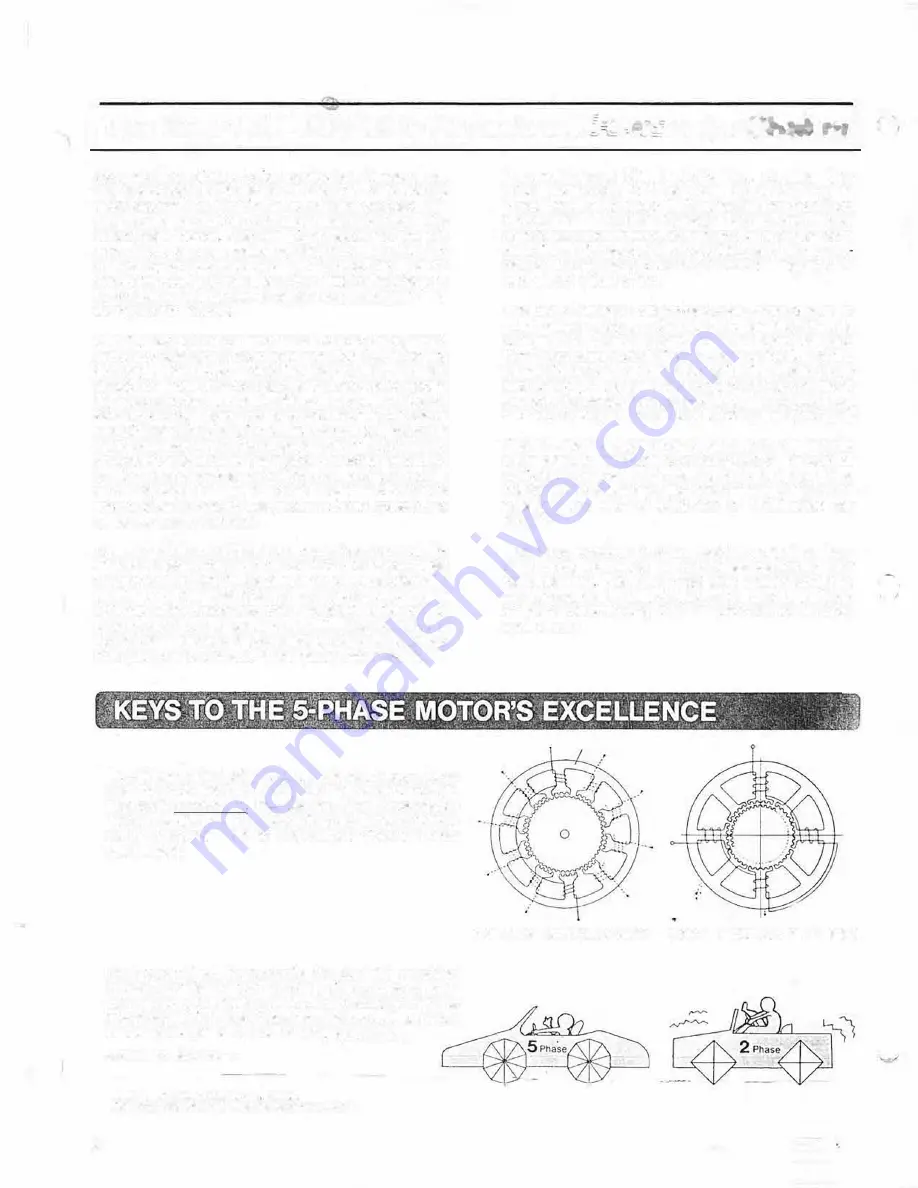

The difference in design between standard step motors

and the Five-Phase is subtle. but the performance dif

ference is

speclacular

Because the Five-Phase design

has an additional pair of magnetic poles. it runs substan

tially smoother wilh no noticeable vibration from

resonances.

As a comparison, for example, the car with ten-sided

wheels provides a much smoother ride that its counter

part with square wheels. This is roughly analogous to the

five pole pairs in a Five-Phase, and the 1wo pole pairs in a

standard two phase (or lour phase) step motor.

(continued next page)

Motor and dnvcr are covered by U.S Patents

fw�Phaso motors ate made under hcense ot Be

r

ger

-

La

lu

.

The engineers at Oriental Motor have elevated Five

Phase technology to a new level by developing the

innovative New-Pentagon UPD series of Five-Phase step

motor/driver. The New-Pentagon series step motor

drivers have even lower vibration and lower current con

sumption at high speeds (above 3,000 pps). This new ver

sion is also very easy to hook-up due to having only five

lead wires instead of ten.

This New-Pentagon design provides

more

torque to

much higher speeds with ex1rernely low vibrat1on. As

compared to a standard slep motor, the New-Pentagon

Five-Phase step motor/driver has only a fraction of the

torque npple for a quantum reduction in vibration (see

next section). Plus. the New·Pentagon driver can move

the motor to speeds in excess of 6.000 rpm (100,000 pps),

and has no torque drop-off to over 600 rpm (10,000 pps).

This new technology makes it possible for all of these

advantages to be obtained at only 75% of the cost of

equivalent microstep drivers. The New-Pentagon Five

Phase driver design also allows for half-stepping, for an

excellen1 resolution of 0.36/step or 1,000 steps per

revolution.

Five-Phase products are now used ln everything from

color copy machines to automated semiconductor

manufacturing The Five-Phase step motor's ability to

move smoothly with little vibration and without the effects

ol resonance is the key to its selection for use in these

applications.

FIVE PHASE STATOR DESIGN

2 OR 4 PHASE STATOR DESIGN