3

How to install the motor

●

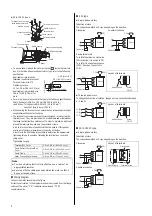

Round shaft type

Drill holes on the mounting plate and fix the motor on the plate using

screws, nuts, and washers (not supplied). Be careful there is no gap

between the motor installation surface and the bracket.

Motor

Mounting screws

Mounting plate

Nuts

Washers

First number of

motor model

Nominal diameter of

screw

Tightening torque

2

M4

2.0 N·m (17.7 lb-in)

4

M5

2.5 N·m (22 lb-in)

5

M6

3.0 N·m (26 lb-in)

Note

Do not insert the motor into the mounting hole at an angle or

force it in, as this may scratch the flange pilot section and

damage the motor.

●

Pinion shaft type

Drill holes on the mounting plate and fix the motor and gearhead on the

plate using screws supplied with the gearhead. Be careful there is no gap

between the motor flange and the gearhead. For details of installation, see

the operating manual provided with the gearhead, which is sold separately.

Motor

Gearhead

Screws provided

with gearhead

Mounting plate

Nuts

Washers

Note

Use the gearhead with pinion shaft which is identical with one of

motor.

●

Motor with cooling fan

When installing a motor with cooling fan onto a device, leave 10 mm

(0.39 in.) or more behind the fan cover or open a ventilation hole so that

the cooling inlet on the back of the motor cover is not blocked.

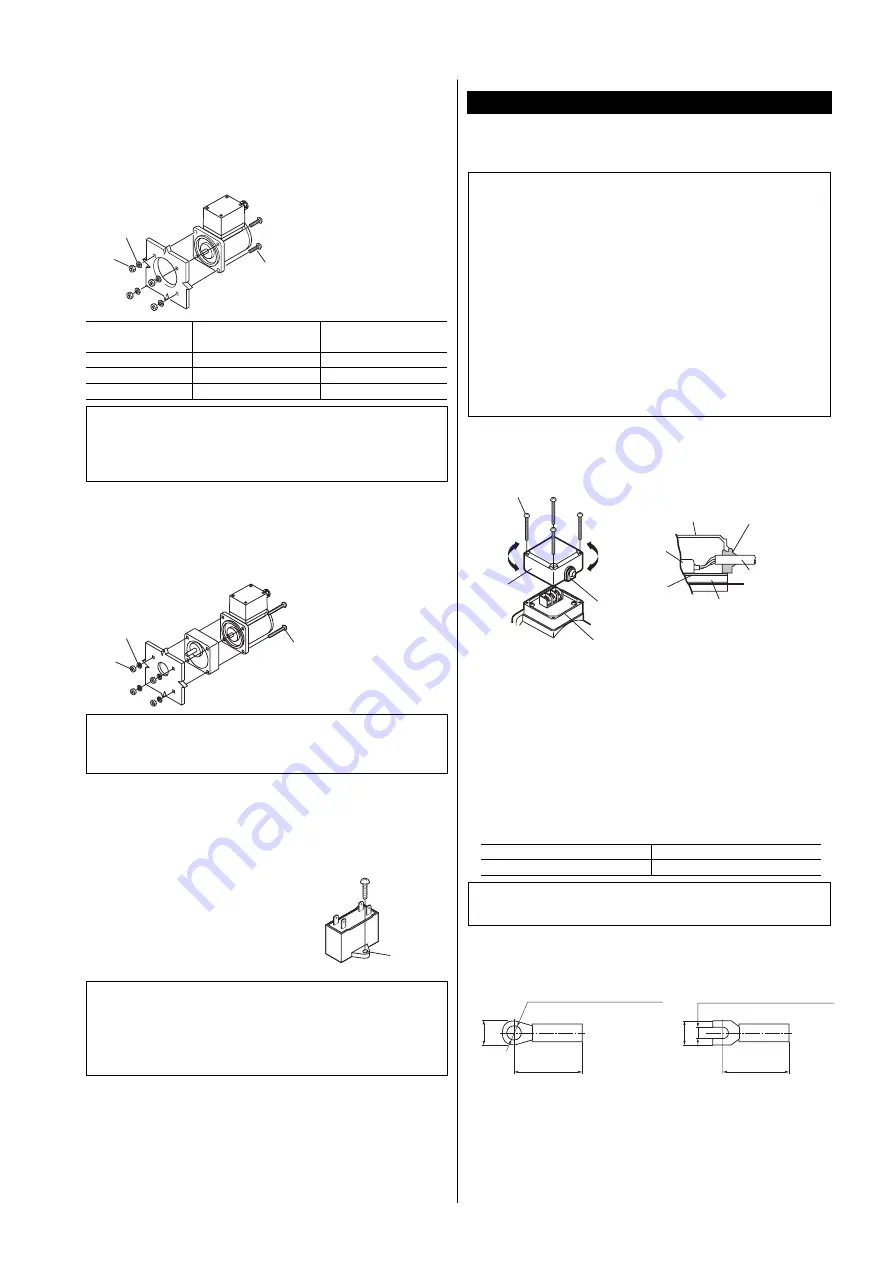

Mounting the capacitor (Only for single-phase motors)

Before mounting the provided capacitor,

check that the capacitor’s capacitance matches

that stated on the motor’s name plate. Mount

the capacitor securely by using M4 screws

(not provided).

Ø4.3 mm

(Ø0.169 in.)

Note

Do not let the screw fastening torque exceed 1 N·m (8.8 lb-in)

to prevent damage to the mounting foot.

Mount capacitor at least 10 cm (3.94 in.) away from the motor.

If it is located closer, the life of the capacitor will be shortened.

Connection and operation

Insulate all the wire connections, such as the connection between the

motor and the capacitor connection. Use the supplied capacitor cap to

insulate the capacitor terminal connection.

Note

Insulation class of this motor is B.

Make sure that the motor case temperature does not exceed

90 °C (194 °F) during operation of the motor. Operation

exceeding case temperature 90 °C (194 °F) may significantly

deteriorate the coils and ball bearings of the motor and shorten

the motor’s life span. Motor case temperature can be

measured by fixing a thermometer on the motor surface. It can

also be measured using thermo tape or a thermocouple.

To change rotation direction of the single-phase induction

motor, wait until the motor completely stops. Otherwise its

direction may not change or may take much time to change.

Single-phase motors use a capacitor and keep it connected

even after rotation of the motor has started.

Connection method to a terminal box

●

6 W types

Rubber bush

Terminal

cover screws

Rubber seat

Rubber seat

Terminal

box cover

Rubber bush

Cable

Terminal plinth

Terminal box cover

Terminal

block

•

For wiring, be sure to use cable that meets the following specifications.

Cable: Diameter is Ø6.8 to 8.6 mm (Ø0.27 to 0.33 in.)

•

When sealing the terminal cover, ensure that no scraps or particles get

caught between the contact surfaces.

•

In order to maintain a tight seal around the terminal box, the rubber seat

use between terminal box cover and terminal plinth. Also this terminal

box is constructed to hold a rubber seat. If this rubber comes out of the

box, please seat it correctly on the box.

•

Also refer to the tightening torque table to determine the appropriate

tightening torque to use when fastening the terminal box cover and

terminal block.

Terminal box cover

0.3 N·m (42 oz-in.)

Motor connecting terminals

0.8 to 1.0 N·m (113 to 142 oz-in.)

Note

Use a cable of an appropriate diameter.

Appropriate terminal strip

Ring terminal with insulation

Fork terminal with insulation

Ø3.6 mm (Ø0.14 in.) or more

Ø3.6 mm (Ø0.14 in.) or more

18 mm (0.71 in.) or less

7.2 mm (0.283 in.) or less

18 mm (0.71 in.) or less

6.4 mm (0.25in.) or less

•

Cable entry is possible at any of the four sides of the terminal box.

Undo the screws which fixed terminal box to the motor case, position

the terminal box so that the outlet faces in the desired direction and re

fasten the screws.