Installation

−9−

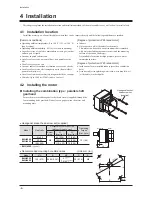

Removing/Installing the gearhead

See the following steps to replace the gearhead or to change the cable position.

1. Removing the gearhead

Remove the hexagonal socket head screws assembling the

motor and gearhead and detach the motor from the gearhead.

Hexagonal socket head screw

•

Assembly hexagonal socket head screw

Model

Screw size

Tightening torque

BMU6200

BMU6400

M3

0.6 N·m (5.3 lb-in)

2. Installing the gearhead

Using the pilot sections of the motor and gearhead as guides,

install the gearhead to the motor and tighten the hexagonal

socket head screws.

Confirm that no gaps remain between the motor flange

surface and the end face of the gearhead pilot section.

At this time, the motor cable position can be changed to a

desired 90° direction.

When installing the gearhead, slowly rotate it clockwise/

counterclockwise to prevent the pinion of the motor output

shaft from contacting the side panel or gear of the gearhead.

Install using pilot

sections as guides

Change the cable

position to a desired

90° direction.

Note

•

Do not forcibly assemble the motor and gearhead. Also, do not let metal objects or other foreign

matter enter the gearhead. The pinion of the motor output shaft or gear may be damaged,

resulting in noise or shorter service life.

•

Do not allow dust to attach to the pilot sections of the motor and gearhead. Also, assemble the

motor and gearhead carefully by not pinching the O-ring at the motor pilot section. If the O-ring is

crushed or severed, grease may leak from the gearhead.

•

The hexagonal socket head screws assembling the motor and gearhead are used to attach the

motor and gearhead temporarily. When installing the motor/gearhead assembly, be sure to use

the supplied hexagonal socket head screws.

Installing the round shaft type

Secure the motor with hexagonal socket head screws (not supplied) through

the four mounting holes provided.

Do not leave a gap between the motor and mounting plate.

Install the motor to a mounting plate of the following size or larger, so that

the motor case temperature will not exceed 90 °C (194 °F).

Hexagonal socket head screw

(not supplied)

Model

Size of mounting plate

[mm (in.)]

Thickness

[mm (in.)]

Material

BMU5200

200×200 (7.87×7.87)

5 (0.20)

Aluminum alloy

BMU5400

250×250 (9.84×9.84)

6 (0.24)

•

Applicable mounting screw

Model

Screw size

Tightening torque

BMU5200

BMU5400

M8

15.5 N·m (137 lb-in)

[12 N·m (106 lb-in) ]

*

*

The brackets [ ] indicate the value for stainless steel.

•

Recommended mounting hole dimensions

[Unit: mm (in.)]

Model

ØA

B

ØC

*

D

ØC

B

B

ØA

4×D

BMU5200

BMU5400

104 (4.09)

73.54 (2.895)

83

+ 0.035

0

(3.2677

+ 0.0014

0

)

M8 or

Ø8.5 (0.335)

*

ØC indicates the pilot diameter on the flange.

Note

Do not install the motor to the mounting hole diagonally or assemble the motor forcibly.

Doing so may cause damage to the flange pilot section, thereby resulting in damage to the motor.

Summary of Contents for BMU5200A Series

Page 43: ...43...