10

Setting item

z

Highest speed

The highest speed of the Speed1 is selected with the SPD H/L switch (function

setting switch No.1).

Select either 200 r/min or 600 r/min for the highest speed.

The speed, which can be set with the speed setting switch, differs in

200 r/min and 600 r/min. Check a desired speed with the tables on p.14 to

p.15.

OFF: 600 r/min

ON: 200 r/min

Factory setting: OFF (600 r/min)

z

Setting method for the Speed2

The setting method for the Speed2 is selected with the SPD2 EN (function

setting switch No.2).

OFF: Fixed to a 10% speed of the Speed1

ON: Selected one from 16 different speeds in a range of 0.5 to 50% of the

Speed1

Factory setting: OFF (Fixed to a 10% speed of the Speed1)

z

Operating speed

The operating speed varies depending on the setting pattern.

•

Pattern 1

y

Speed1 ...........Check a desired speed from 256 different speeds in the tables

on p.14, and set using a combination of the ×16/SPD1 switch

and the ×1/SPD2 switch.

y

Speed2 ...........This is fixed to a 10% speed of the Speed1.

•

Pattern 2

y

Speed1 ...........Check a desired speed from 16 different speeds in the tables

on p.15, and set with the ×16/SPD1 switch.

y

Speed2 ...........Check a desired speed from 16 different speeds in the tables

on p.15, and set with the ×1/SPD2 switch.

z

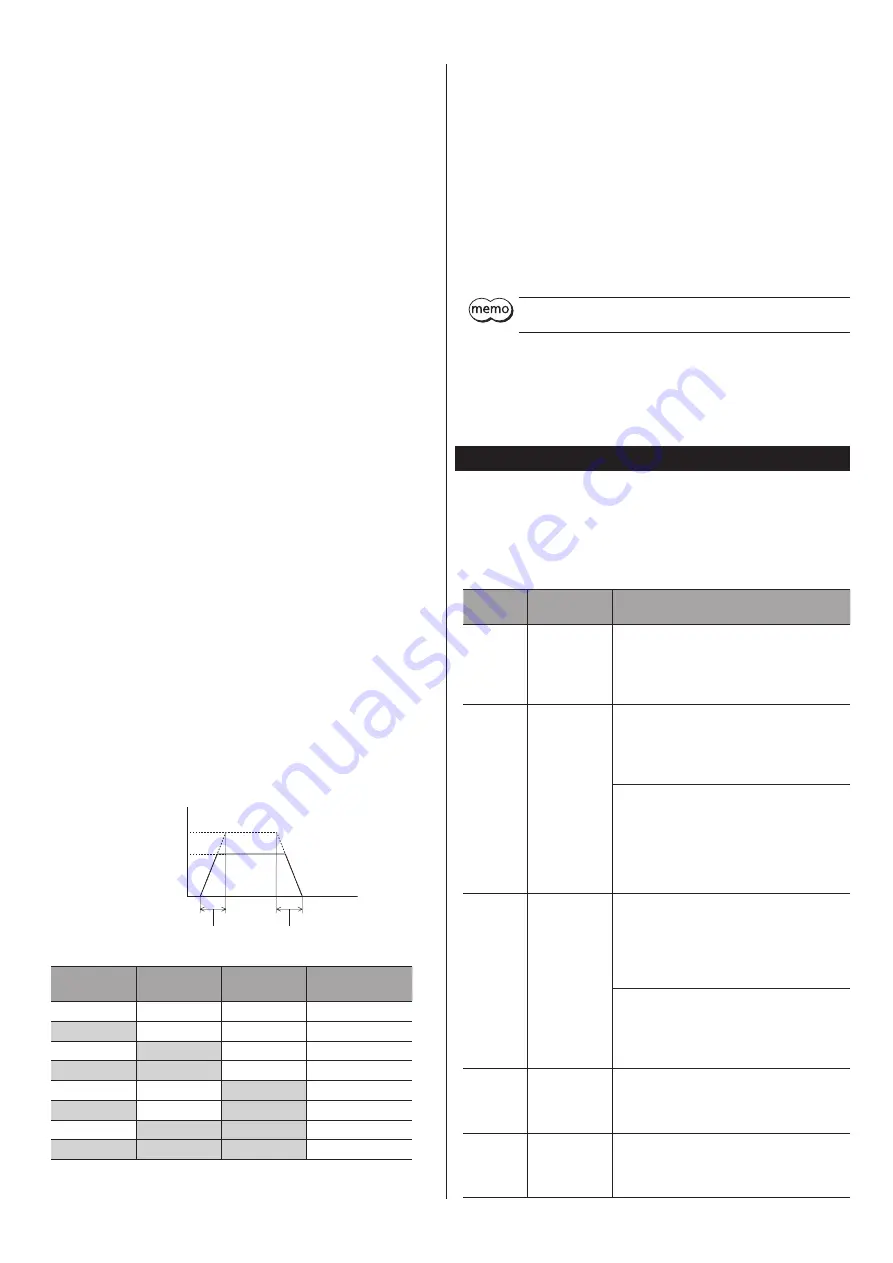

Acceleration time and deceleration time

The acceleration time refers to the time needed for the operating speed to

reach 600 r/min from 0 r/min. The deceleration time refers to the time needed

for the operating speed to reach 0 r/min from 600 r/min. The same time is

applied to all of the acceleration, deceleration, and changing speed.

Set using the ACC0 to ACC2 switches (function setting switch No.4 to No.6).

Factory setting: 0.50 s

Time [s]

Acceleration

time

Deceleration

time

Speed [r/min]

600

Setting speed

ACC0 (No.4)

ACC1 (No.5)

ACC2 (No.6)

Acceleration time

Deceleration time

OFF

OFF

OFF

0.00 s

ON

OFF

OFF

0.05 s

OFF

ON

OFF

0.10 s

ON

ON

OFF

0.20 s

OFF

OFF

ON

0.50 s

ON

OFF

ON

1.00 s

OFF

ON

ON

2.00 s

ON

ON

ON

3.00 s

z

Operating current rate and standstill current rate

•

Operating current rate

If the load is small and there is an ample allowance for torque, the motor

temperature rise can be suppressed by setting a lower operating current rate.

The actual operating current is a value that the rated operating current of the

driver is multiplied by the operating current rate.

Operating current = Driver rated current × Operating current rate

Select the operating current rate using the RUN switch (function setting

switch No.3).

OFF: Operating current rate 100%

ON: Operating current rate 70%

Factory setting: OFF (100%)

Set the operating current rate to 70% when using the

CVD524BR-

KSC

with an accessory circuit product cover.

•

Standstill current rate

When the motor stops, the current cutback function will be actuated to lower

the motor current to the standstill current. The standstill current rate is 50% of

the operating current.

Standstill current = Operating current × 50%

Alarm

When the driver's protective function triggers and an alarm generates, the

ALM output is turned OFF and the motor current is cut off. At the same time,

the PWR/ALM LED will blink in red. The cause of the alarm can be checked by

counting the number of times the PWR/ALM LED blinks.

Alarm list

Number of

LED blinks

Alarm type

Cause and remedial action

2

Overheat

[Cause]

The temperature of the driver circuit board

reached 85 °C (185 °F).

[Remedial action]

Review the ventilation condition.

3

Overvoltage

[Cause]

A voltage exceeding the specification value was

applied.

[Remedial action]

Check the input voltage of the power supply.

[Cause]

A large inertial load was stopped abruptly or

vertical operation was performed.

[Remedial action]

If this alarm generates during operation, reduce

the load or increase the acceleration/deceleration

time.

5

Overcurrent

[Cause]

An excessive current was flowed through the

driver output circuit for motor.

[Remedial action]

Turn off the power and check that the motor,

cable and driver are not damaged.

[Cause]

The motor was made a quick stop or a rapid

deceleration.

[Remedial action]

Review the operating conditions.

9

EEPROM error

[Cause]

The stored data in the driver was damaged.

[Remedial action]

Contact your nearest Oriental Motor sales office.

Lit

CPU error

[Cause]

CPU malfunctioned.

[Remedial action]

Cycle the power.