15

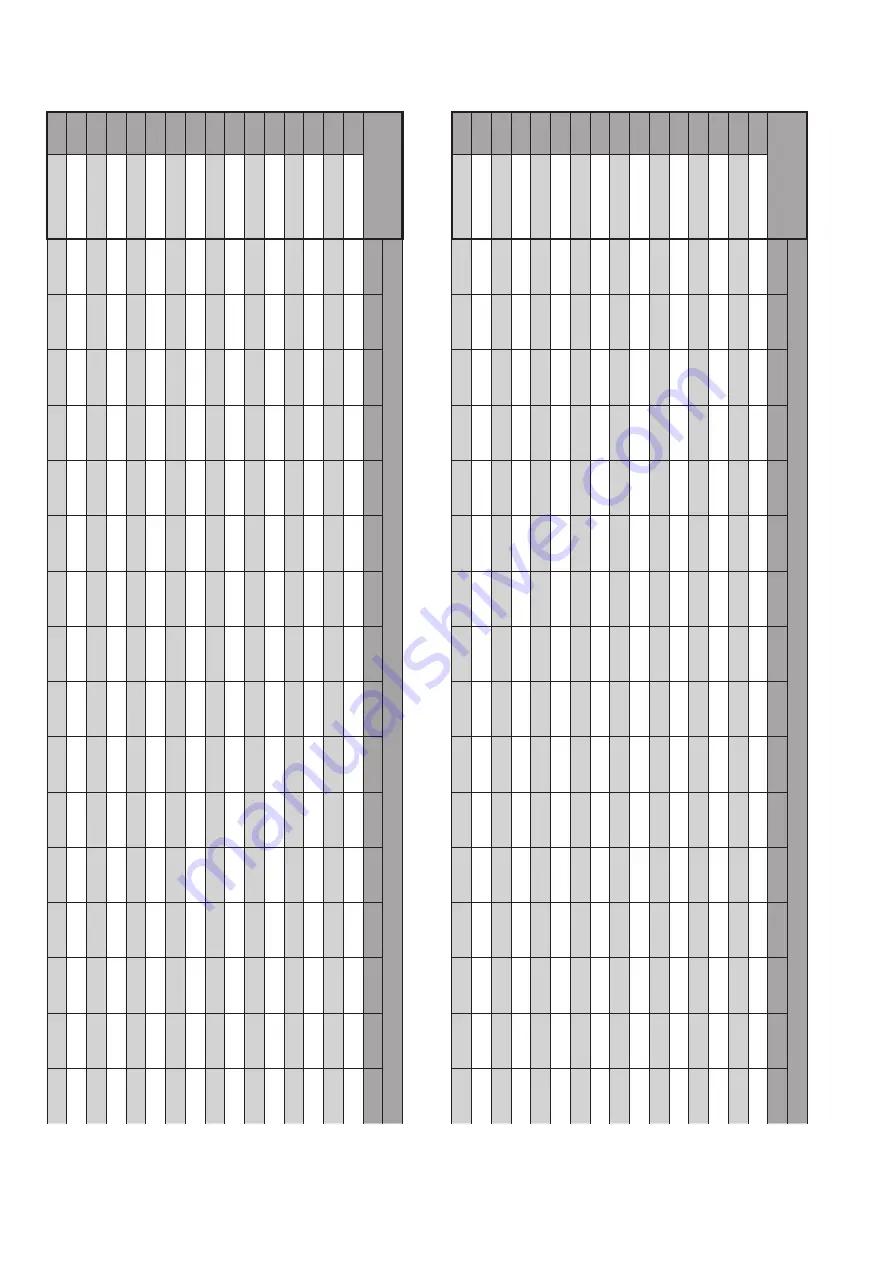

Pattern 2

z

List of Sp

eed1 and Sp

eed2 f

or when the highest sp

eed is 600 r/min (r/min)

×16/SPD1 swit

ch

(Speed1)

×1/SPD2 swit

ch (Speed2)

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

225 r/min

1.1250

2.2500

4.5000

6.7500

9.0000

11.2500

16.8750

22.5000

33.7500

45.0000

56.2500

67.5000

78.7500

90.0000

101.2500

112.5000

1

250 r/min

1.2500

2.5000

5.0000

7.5000

10.0000

12.5000

18.7500

25.0000

37.5000

50.0000

62.5000

75.0000

87.5000

100.0000

112.5000

125.0000

2

275 r/min

1.3750

2.7500

5.5000

8.2500

11.0000

13.7500

20.6250

27.5000

41.2500

55.0000

68.7500

82.5000

96.2500

110.0000

123.7500

137.5000

3

300 r/min

1.5000

3.0000

6.0000

9.0000

12.0000

15.0000

22.5000

30.0000

45.0000

60.0000

75.0000

90.0000

105.0000

120.0000

135.0000

150.0000

4

325 r/min

1.6250

3.2500

6.5000

9.7500

13.0000

16.2500

24.3750

32.5000

48.7500

65.0000

81.2500

97.5000

113.7500

130.0000

146.2500

162.5000

5

350 r/min

1.7500

3.5000

7.0000

10.5000

14.0000

17.5000

26.2500

35.0000

52.5000

70.0000

87.5000

105.0000

122.5000

140.0000

157.5000

175.0000

6

375 r/min

1.8750

3.7500

7.5000

11.2500

15.0000

18.7500

28.1250

37.5000

56.2500

75.0000

93.7500

112.5000

131.2500

150.0000

168.7500

187.5000

7

400 r/min

2.0000

4.0000

8.0000

12.0000

16.0000

20.0000

30.0000

40.0000

60.0000

80.0000

100.0000

120.0000

140.0000

160.0000

180.0000

200.0000

8

425 r/min

2.1250

4.2500

8.5000

12.7500

17.0000

21.2500

31.8750

42.5000

63.7500

85.0000

106.2500

127.5000

148.7500

170.0000

191.2500

212.5000

9

450 r/min

2.2500

4.5000

9.0000

13.5000

18.0000

22.5000

33.7500

45.0000

67.5000

90.0000

112.5000

135.0000

157.5000

180.0000

202.5000

225.0000

A

475 r/min

2.3750

4.7500

9.5000

14.2500

19.0000

23.7500

35.6250

47.5000

71.2500

95.0000

118.7500

142.5000

166.2500

190.0000

213.7500

237.5000

B

500 r/min

2.5000

5.0000

10.0000

15.0000

20.0000

25.0000

37.5000

50.0000

75.0000

100.0000

125.0000

150.0000

175.0000

200.0000

225.0000

250.0000

C

525 r/min

2.6250

5.2500

10.5000

15.7500

21.0000

26.2500

39.3750

52.5000

78.7500

105.0000

131.2500

157.5000

183.7500

210.0000

236.2500

262.5000

D

550 r/min

2.7500

5.5000

11.0000

16.5000

22.0000

27.5000

41.2500

55.0000

82.5000

110.0000

137.5000

165.0000

192.5000

220.0000

247.5000

275.0000

E

575 r/min

2.8750

5.7500

11.5000

17.2500

23.0000

28.7500

43.1250

57.5000

86.2500

115.0000

143.7500

172.5000

201.2500

230.0000

258.7500

287.5000

F

600 r/min

3.0000

6.0000

12.0000

18.0000

24.0000

30.0000

45.0000

60.0000

90.0000

120.0000

150.0000

180.0000

210.0000

240.0000

270.0000

300.0000

z

List of Sp

eed1 and Sp

eed2 f

or when the highest sp

eed is 200 r/min (r/min)

×16/SPD1 swit

ch

(Speed1)

×1/SPD2 swit

ch (Speed2)

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

12.5 r/min

0.0625

0.1250

0.2500

0.3750

0.5000

0.6250

0.9375

1.2500

1.8750

2.5000

3.1250

3.7500

4.3750

5.0000

5.6250

6.2500

1

25.0 r/min

0.1250

0.2500

0.5000

0.7500

1.0000

1.2500

1.8750

2.5000

3.7500

5.0000

6.2500

7.5000

8.7500

10.0000

11.2500

12.5000

2

37.5 r/min

0.1875

0.3750

0.7500

1.1250

1.5000

1.8750

2.8125

3.7500

5.6250

7.5000

9.3750

11.2500

13.1250

15.0000

16.8750

18.7500

3

50.0 r/min

0.2500

0.5000

1.0000

1.5000

2.0000

2.5000

3.7500

5.0000

7.5000

10.0000

12.5000

15.0000

17.5000

20.0000

22.5000

25.0000

4

62.5 r/min

0.3125

0.6250

1.2500

1.8750

2.5000

3.1250

4.6875

6.2500

9.3750

12.5000

15.6250

18.7500

21.8750

25.0000

28.1250

31.2500

5

75.0 r/min

0.3750

0.7500

1.5000

2.2500

3.0000

3.7500

5.6250

7.5000

11.2500

15.0000

18.7500

22.5000

26.2500

30.0000

33.7500

37.5000

6

87.5 r/min

0.4375

0.8750

1.7500

2.6250

3.5000

4.3750

6.5625

8.7500

13.1250

17.5000

21.8750

26.2500

30.6250

35.0000

39.3750

43.7500

7

100.0 r/min

0.5000

1.0000

2.0000

3.0000

4.0000

5.0000

7.5000

10.0000

15.0000

20.0000

25.0000

30.0000

35.0000

40.0000

45.0000

50.0000

8

112.5 r/min

0.5625

1.1250

2.2500

3.3750

4.5000

5.6250

8.4375

11.2500

16.8750

22.5000

28.1250

33.7500

39.3750

45.0000

50.6250

56.2500

9

125.0 r/min

0.6250

1.2500

2.5000

3.7500

5.0000

6.2500

9.3750

12.5000

18.7500

25.0000

31.2500

37.5000

43.7500

50.0000

56.2500

62.5000

A

137.5 r/min

0.6875

1.3750

2.7500

4.1250

5.5000

6.8750

10.3125

13.7500

20.6250

27.5000

34.3750

41.2500

48.1250

55.0000

61.8750

68.7500

B

150.0 r/min

0.7500

1.5000

3.0000

4.5000

6.0000

7.5000

11.2500

15.0000

22.5000

30.0000

37.5000

45.0000

52.5000

60.0000

67.5000

75.0000

C

162.5 r/min

0.8125

1.6250

3.2500

4.8750

6.5000

8.1250

12.1875

16.2500

24.3750

32.5000

40.6250

48.7500

56.8750

65.0000

73.1250

81.2500

D

175.0 r/min

0.8750

1.7500

3.5000

5.2500

7.0000

8.7500

13.1250

17.5000

26.2500

35.0000

43.7500

52.5000

61.2500

70.0000

78.7500

87.5000

E

187.5 r/min

0.9375

1.8750

3.7500

5.6250

7.5000

9.3750

14.0625

18.7500

28.1250

37.5000

46.8750

56.2500

65.6250

75.0000

84.3750

93.7500

F

200.0 r/min

1.0000

2.0000

4.0000

6.0000

8.0000

10.0000

15.0000

20.0000

30.0000

40.0000

50.0000

60.0000

70.0000

80.0000

90.0000

100.0000