2

•

Area that is free from an explosive atmosphere or toxic gas (such as sulfuric gas) or

liquid

•

Area not exposed to direct sun

•

Area free of excessive amount dust, iron particles or the like

•

Area free of excessive salt

•

Area not subject to continuous vibration or excessive shocks

•

Area free of excessive electromagnetic noise (from welders, power machinery, etc.)

•

Area free of radioactive materials, magnetic fields or vacuum

•

Altitude Up to 1000 m (3300 ft.) above sea level

[ Degree of protection IP66 rated motor ]

•

Indoors

•

Not exposed to oil (oil droplets) or chemicals.

The motor can be used in an environment that is splashed with water (excluding

the mounting surface of the round shaft type).

Not available for use under high pressure jets of water or immersion in water.

[ Degree of protection IP54/20 rated motor ]

•

Inside an enclosure that is installed indoors (provide vent holes)

•

Area not subject to splashing water (storms, water droplets), oil (oil droplets) or

other liquids

Note

On rare occasions, grease may ooze out from the gearhead. If there

is a concern over possible environmental damage resulting from the

leakage of grease, provide an oil tray or similar oil catching mechanism

in order not to cause a secondary damage. Grease leakage may lead to

problems in the customer's equipment or products.

Installation method

Note

Do not install the motor to the mounting hole diagonally or assemble

the motor forcibly. Doing so may cause damage to the motor.

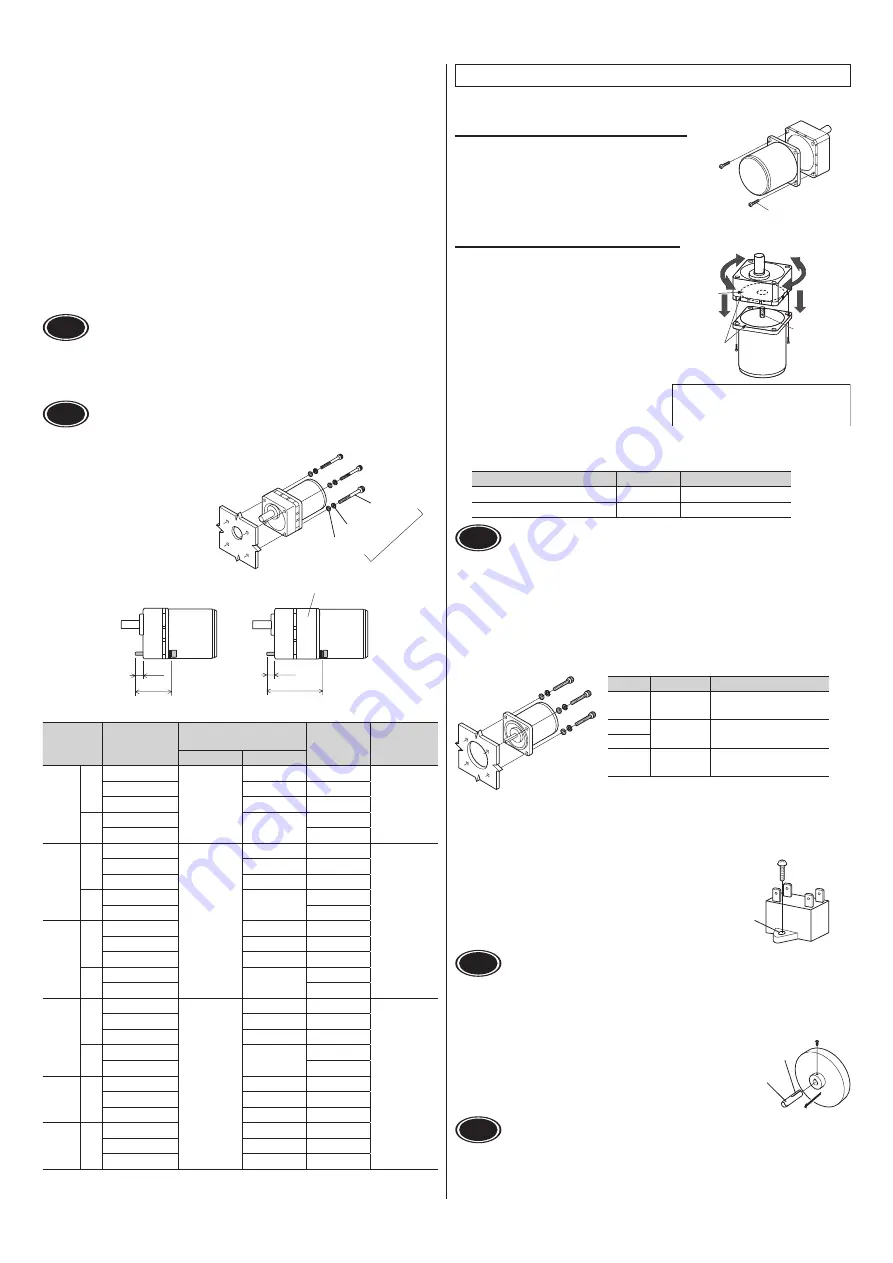

z

Combination type

Secure the motor with mounting

screw set (supplied) through the

four mounting holes provided.

Do not leave a gap between the

motor and mounting plate.

Motor

Hexagonal

socket head

screw

Gearhead

Mounting plate

Spring

washer

Washer

Supplied

Motor

Motor

Gearhead

Gearhead

(L2)

L1

(L2)

L1

①

②

Decimal gearhead

Mounting screw set (supplied)

Material: Stainless steel

Model

Gear ratio

Hexagonal socket head

screw

L2 [mm (in.)] Tightening

torque

Screw size L1 [mm (in.)]

2IK6

①

2, 3, 30 to 120

M4

55 (2.17)

8 (0.31)

1.4 N·m

(12.3 lb-in)

5 to 25

50 (1.97)

7 (0.28)

150 to 360

60 (2.36)

8 (0.31)

②

500 to 1200

90 (3.54)

14 (0.55)

1500 to 3600

9 (0.35)

3IK15

①

2, 3, 30 to 120

M6

65 (2.56)

12 (0.47)

5.0 N·m

(44 lb-in)

5 to 25

60 (2.36)

12 (0.47)

150 to 360

70 (2.76)

12 (0.47)

②

500 to 1200

100 (3.94)

13 (0.51)

1500 to 3600

8 (0.31)

4IK25

①

2, 3, 30 to 120

65 (2.56)

9 (0.35)

5 to 25

60 (2.36)

9 (0.35)

150 to 360

70 (2.76)

9 (0.35)

②

500 to 1200

110 (4.33)

15 (0.59)

1500 to 3600

10 (0.39)

5IK40

①

2, 3, 25 to 100

M8

85 (3.35)

16 (0.63)

12.0 N·m

(106 lb-in)

5 to 18

70 (2.76)

14 (0.55)

120 to 300

90 (3.54)

15 (0.59)

②

360 to 1000

130 (5.12)

18 (0.71)

1200 to 3000

12 (0.47)

5IK60

①

2, 3, 25 to 100

85 (3.35)

16 (0.63)

5 to 18

70 (2.76)

14 (0.55)

120 to 300

90 (3.54)

15 (0.59)

5IK90

①

3, 18 to 36

85 (3.35)

16 (0.63)

5 to 15

70 (2.76)

14 (0.55)

50 to 180

95 (3.74)

14 (0.55)

Removing and assembling the gearhead and the decimal gearhead

See the following steps to replace the gearhead or to change the outlet position of

the lead wires and the position of the terminal box.

Removing the gearhead from the motor

Remove the hexagonal socket head screws (2 places)

assembling the motor, gearhead and decimal

gearhead, and detach the gearhead and decimal

gearhead from the motor.

Hexagonal socket

head screw

Assembling the gearhead to the motor

1.

Keep the pilot sections of the

motor and gearhead in parallel,

and assemble the gearhead with

the motor while slowly rotating it

clockwise/counterclockwise.

At this time, note so that the pinion

of the motor output shaft does not

hit the side panel or gears of the

gearhead strongly.

2.

Check no gaps remain between the

motor and gearhead, and tighten

them with hexagonal socket head

screws (2 pieces).

When using a decimal gearhead,

install it between the motor and the

gearhead.

Pinion of

the motor

output shaft

Pilot section

Assemble the gearhead to the motor

in a condition where the motor output

shaft is in an upward direction.

Side panel

Gearhead model

Screw size

Tightening torque

2GV

B

,

3GV

B

,

4GV

B

M2.6

0.4 N·m (3.5 lb-in)

5GV

B

,

5GVH

B

,

5GVR

B

M3

0.6 N·m (5.3 lb-in)

Note

•

Do not forcibly assemble the motor and gearhead. Also, prevent

metal objects or foreign substances from entering in the gearhead.

The pinion of the motor output shaft or gear may be damaged,

resulting in noise or shorter service life.

•

O-rings are attached on the motor flange and the mounting surface

of the decimal gearhead. Install the gearhead so as not to pinch the

O-rings. Grease in the gearhead may leak.

z

Round shaft type

Secure the motor with hexagonal socket head screws (not supplied) through the

four mounting holes provided. Do not leave a gap between the motor and mounting

plate.

Motor

Mounting plate

Model Screw size

Tightening torque

2IK

M4

1.8 N·m (15.9 lb-in)

[1.4 N·m (12.3 lb-in)]

3IK

M5

3.8 N·m (33 lb-in)

[3.0 N·m (26 lb-in)]

4IK

5IK

M6

6.4 N·m (56 lb-in)

[5.0 N·m (44 lb-in)]

The brackets [ ] indicate the value for stainless steel.

z

Motor with cooling fan

When installing a motor with cooling fan onto a device, leave 10 mm (0.39 in.) or

more behind the fan cover or open a ventilation hole so that the cooling inlet on the

back of the motor cover is not blocked.

z

Mounting the capacitor

Mount the capacitor securely by using M4 screws (not

provided).

Ø4.3 mm

(0.169 in.)

Note

•

Do not let the screw fastening torque exceed 1 N·m (8.8 lb-in) to

prevent damage to the mounting foot.

•

Mount capacitor at least 10 cm (3.94 in.) away from the motor. If it

is located closer, the life of the capacitor will be shortened.

Installing a load

The gearhead shaft is provided with a key slot for

connecting the transmission parts. When connecting

the transmission parts, ensure that the shaft and parts

have a clearance fit, and always fix the parallel key

to the output shaft with a screw to prevent the parts

from rattling or spinning.

Screw

Parallel key

Gearhead

output shaft

Note

Do not apply excessive force onto the output shaft of the gearhead

using a hammer or other tools. Doing so may cause damage to the

output shaft or bearings.