6

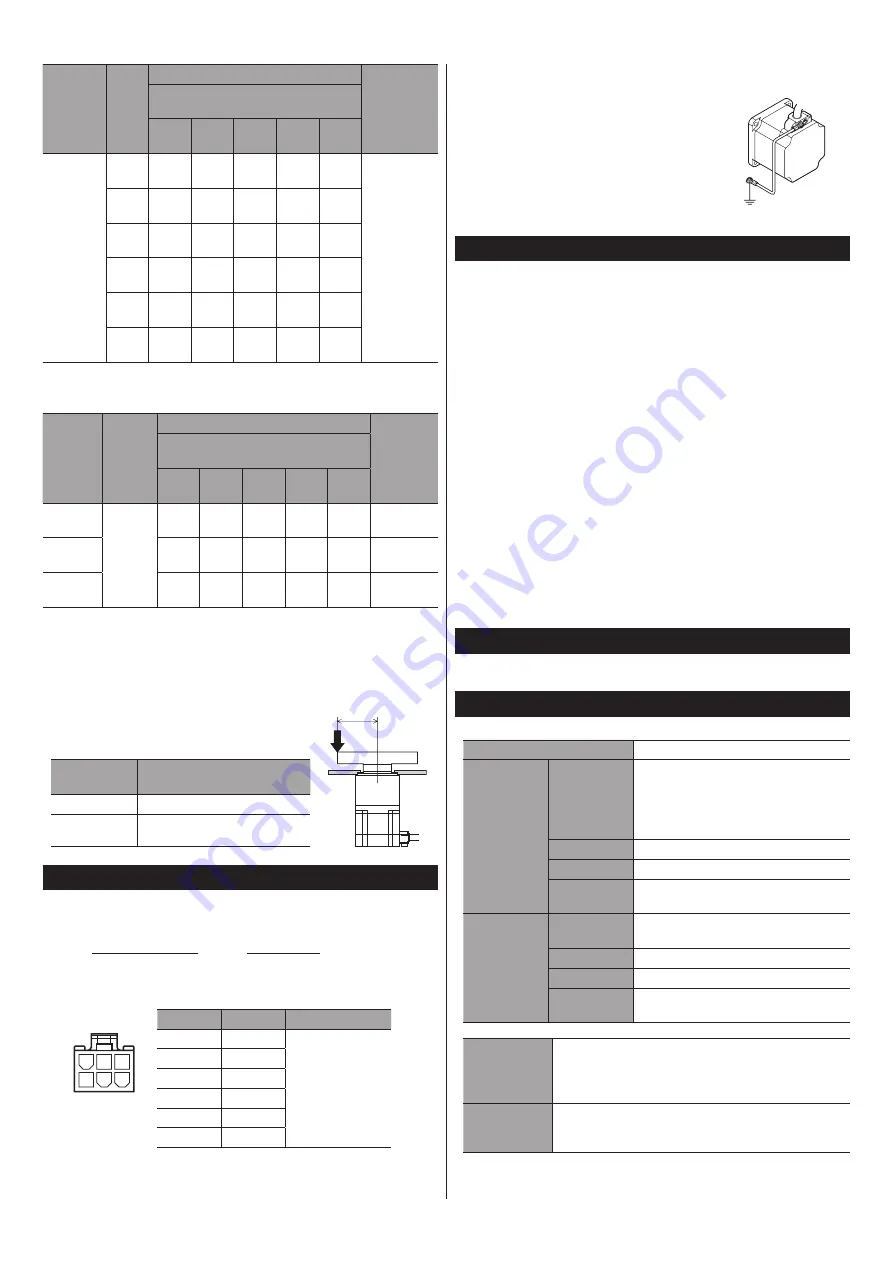

Motor

model

Gear

ratio

Permissible radial load [N (lb.)]

Permissible

axial load

[N (lb.)]

Distance from the tip of motor’s output

shaft [mm (in.)]

0

(0)

5

(0.2)

10

(0.39)

15

(0.59)

20

(0.79)

PKE59

5

380

(85)

420

(94)

470

(105)

540

(121)

630

(141)

600 (135)

7.2

430

(96)

470

(105)

530

(119)

610

(137)

710

(159)

10

480

(108)

530

(119)

590

(132)

680

(153)

790

(177)

25

650

(146)

720

(162)

810

(182)

920

(200)

1070

(240)

36

730

(164)

810

(182)

910

(200)

1040

(230)

1210

(270)

50

820

(184)

910

(200)

1020

(220)

1160

(260)

1350

(300)

z

Harmonic geared type

Motor

model

Gear ratio

Permissible radial load [N (lb.)]

Permissible

axial load

[N (lb.)]

Distance from the tip of motor’s output

shaft [mm (in.)]

0

(0)

5

(0.2)

10

(0.39)

15

(0.59)

20

(0.79)

PKE54

All gear

ratios

180

(40)

220

(49)

270

(60)

360

(81)

510

(114)

220 (49)

PKE56

320

(72)

370

(83)

440

(99)

550

(123)

720

(162)

450 (101)

PKE59

1090

(240)

1150

(250)

1230

(270)

1310

(290)

1410

(310)

1300 (290)

Permissible moment load of the Harmonic geared type

When installing an arm or table on the flange surface, calculate the moment

load using the formula below if the flange surface receives any eccentric load.

The moment load should not exceed the permissible value specified in the

table.

L: Distance from the center of the output flange (m)

F: External force (N)

Moment load: M (N·m) = F × L

L

F

Motor model

Permissible moment load

(N·m)

PKE543

5.6

PKE564

11.6

Connection

Connecting to the driver

Refer to OPERATING MANUAL Driver or USER MANUAL for the connection

method.

•

Motor connector pin assignment

Pin No.

Lead color

Lead size

1

4

2

5

3

6

1

Black

AWG22 (0.3 mm

2

)

2

Red

3

Yellow

4

Blue

5

Orange

6

Green

Grounding the motor

Be sure to ground the Protective Earth Terminal of

the motor.

Screw size: M4

Grounding wire: AWG18 (0.75 mm

2

) or thicker

Tightening torque: 1.2 N·m (170 oz-in)

When grounding, use a round terminal and secure it

with a mounting screw with a washer. Ground wires

and crimp terminals are not supplied.

Grounding

Inspection and maintenance

Inspection

It is recommended that periodic inspections be conducted for the items listed

below after each operation of the motor. If an abnormal condition is noted,

discontinue any use and contact your nearest Oriental Motor sales office.

z

During inspection

y

Are any of motor mounting screws loose?

y

Are there any abnormal noises in the motor bearings (ball bearings) or

other moving parts?

y

Are there any scratches, signs of stress or loose driver connection in the

motor cable?

y

Are the motor’s output shaft and load shaft out of alignment?

Warranty

Check on the Oriental Motor Website for the product warranty.

Disposal

Dispose the product correctly in accordance with laws and regulations, or

instructions of local governments.

Specifications

Check on the Oriental Motor Website for the product specifications.

General specifications

Degree of protection

IP20

Operation

environment

Ambient

temperature

−10 to +50 °C (+14 to +122 °F) (non-freezing)

Standard type with encoder:

0 to +50 °C (+32 to +122 °F) (non-freezing)

Harmonic geared type:

0 to +40 °C (+32 to +104 °F) (non-freezing)

Humidity

85% or less (non-condensing)

Altitude

Up to 1000 m (3300 ft.) above sea level

Surrounding

atmosphere

No corrosive gas, dust, water or oil

Storage

environment

Shipping

environment

Ambient

temperature

−20 to +60 °C (−4 to +140 °F) (non-freezing)

Humidity

85% or less (non-condensing)

Altitude

Up to 3000 m (10000 ft.) above sea level

Surrounding

atmosphere

No corrosive gas, dust, water or oil

Insulation

resistance

100 MΩ or more when 500 VDC megger is applied between

the following places:

y

Case - Motor windings

y

Case - Electromagnetic brake windings

Dielectric

strength

Sufficient to withstand the following for 1 minute:

y

Case - Motor windings 1.5 kVAC 50/60 Hz

y

Case - Electromagnetic brake windings 1.5 kVAC 50/60 Hz