2

Preparation

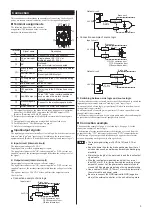

Checkingtheproduct

Verify that the items listed below are included. Report any missing or

damaged items to the branch or sales office from which you purchased the

product.

Brakeypackyyyy1yunit

Flush-mountingysocketyyyy1ypiece

MODEL

SB50W

POWER

ALARM

1-40

W

60-90W

Operatingymanualyyyy1ycopy

Namesandfunctionsofparts

POWER

ALARM

MODEL

SB50W

1-40W

60-90W

SINK

SOURCE

①

②

③

④

No.

Name

Factoryy

setting

Description

①

POWERyindicator

(green)

–

Litywheny24yVDCyisysupplied.

②

ALARMyindicator

(red)

–

LitywhenytheyALARMyoutputyisy

"OFF."

③

Motoryoutput

selectoryswitch

60-90yW Changeytheysettingyofythisyswitchy

accordingytoytheymotoryoutput.

④

Sink/Source

selectoryswitch

SINK

Switchytheycontrolysignalyinput/

outputymodeybetweeny"sinkylogic"y

andy"sourceylogic"y(pagey3).

Applicablemotors

K

Ⅱ

series,

V

series, World

K

series,

FPW

series,

K

series (motor output 1 to 90 W except for the 2-pole type)

Note

Three-phaseymotorsycannotybeyusedyinycombination.

Installation

This section covers the environment and method of installing the brake pack.

Locationforinstallation

Install it in a well-ventilated location that provides easy access for inspection.

The location must also satisfy the following conditions:

y

Inside an enclosure that is installed indoors (provide vent holes)

y

Operating ambient temperature 0 to +40 °C (+32 to +104 °F) (non-freezing)

y

Operating ambient humidity 85% or less (non-condensing)

y

Area that is free of explosive atmosphere or toxic gas (such as sulfuric gas)

or liquid

y

Area not exposed to direct sun

y

Area free of excessive amount dust, iron particles or the like

y

Area not subject to splashing water (storms, water droplets), oil (oil

droplets) or other liquids

y

Area free of excessive salt

y

Area not subject to continuous vibration or excessive shocks

y

Area free of excessive electromagnetic noise (from welders, power

machinery, etc.)

y

Area free of radioactive materials, magnetic fields or vacuum

y

Altitude: Up to 1000 m (3300 ft.) above sea level

Howtoinstallthemotioninterface

The brake pack has been designed on the basis of heat dissipation through air

convection.

Install the brake pack on a metal plate having a high degree of vibration

resistance.

In the presence of a great amount of vibration, do not use a DIN rail. Screw

down the brake pack directly through the use of a flush-mounting socket.

Note

y

•

Thereymustybeyayclearanceyofyatyleasty25ymmy(0.984yin.)yandy

50ymmy(1.97yin.)yinytheyhorizontalyandyverticalydirections,y

respectively,ybetweenytheybrakeypackyandyenclosureyory

otheryequipmentywithinytheyenclosure.

y

•

Doynotyinstallynearytheybrakeypackyanyyequipmentythaty

generatesyaylargeyamountyofyheat.

y

•

Checkyventilationyifytheyambientytemperatureyofytheybrakey

packyexceedsy40y°Cy(104y°F).

z

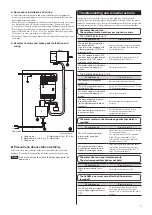

MountingtoDINrail

Use a DIN rail 35 mm (1.38 in.) wide to mount the flush-mounting socket.

1. Engage the hooks on the back of the flush-mounting

socket over the DIN rail, then push the DIN lever

until it locks in place.

DIN lever

2. Insert the brake pack into

the flush-mounting socket.

MO

DEL

SB50W

POWER

ALARM

Mounting hook

1-4

0W

60

-90W

Note

Useytheymountingyhookyofytheyflush-mountingysocketytoylocky

theybrakeypackyinyplace.

z

RemovingfromDINrail

PullytheyDINyleverydownywithyayy–yyscrewdriver,yy

thenyliftytheybottomyofytheyflush-mountingysocketyy

toyremoveyityfromytheyrail.

z

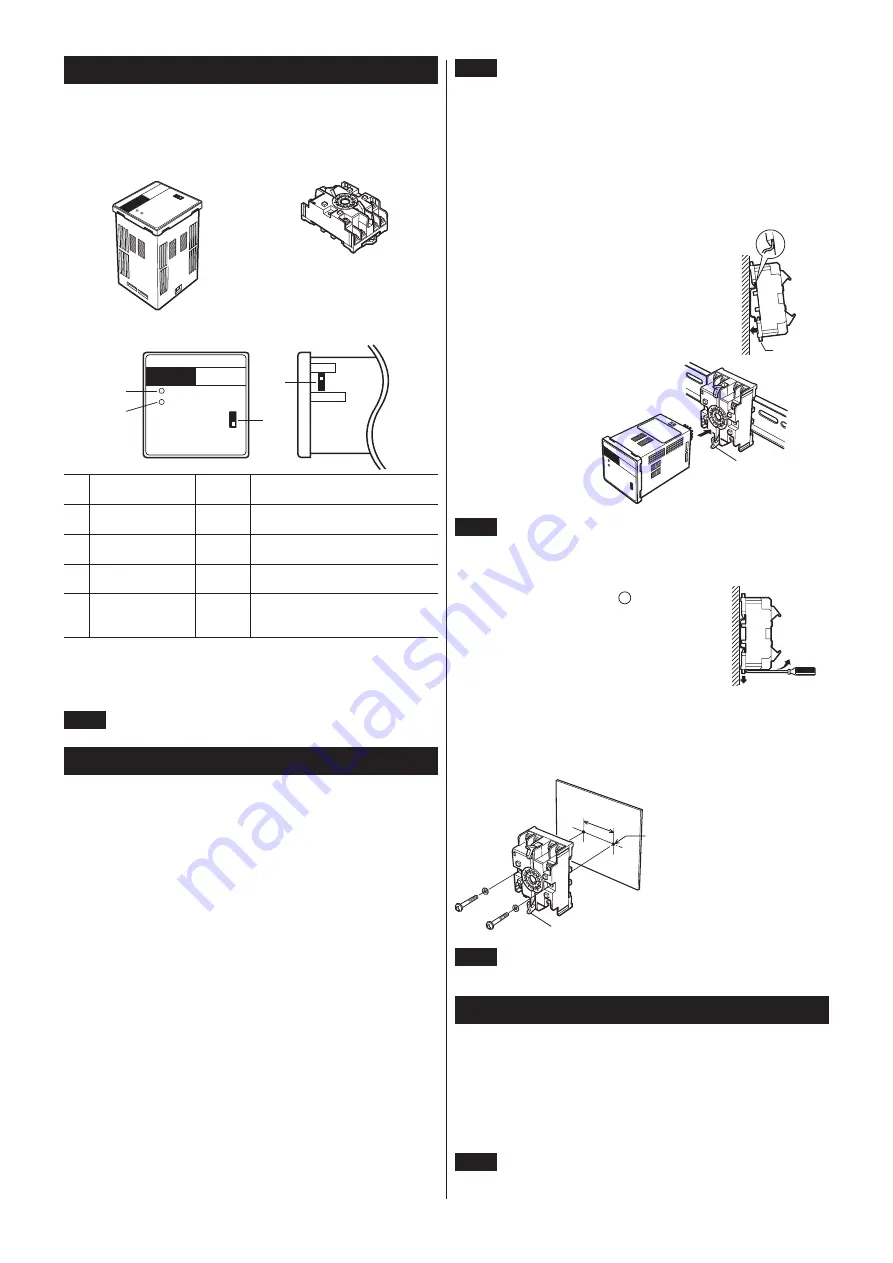

Installingwithscrews

Install the flush-mounting socket by securing it with two bolts (M4 or M3, not

supplied) through the two mounting holes provided. Leave no gap between

the flush-mounting socket and metal plate.

Insert the brake pack into the flush-mounting socket.

2×Ø4.5 (Ø0.177) Mounting holes

40

r

0.2

(1.57

r

0.008

)

Mounting hook

[Unitymmy(in.)]

Note

Useytheymountingyhookyofytheyflush-mountingysocketytoylocky

theybrakeypackyinyplace.

Setting

Switchingmotoroutput

Set the motor output selector switch on the brake pack according to the output

of the motor connected.

Set the switch to "1 - 40 W" when the brake pack is connected to a 1 to 40 W

motor. Set the switch to "60 - 90 W" when the brake pack is connected to a

60 W or 90 W motor.

Factory setting is "60 - 90 W."

Note

Alwaysysetytheymotoryoutputytoytheybrakeypackybeforey

operatingytheymotor.yTheybrakeypackywillynotyacceptyanyy

changesytoytheymotoryoutputysettingywhileytheymotoryisyrunning.