3

Connection

This section covers the methods and examples of connecting the brake pack,

power, motor and external controller, as well as the input/output signals.

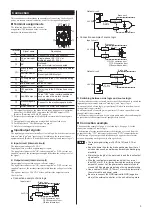

Terminalassignments

The following figure shows the terminal

assignments. The terminals of the socket are

marked with terminal numbers.

2

3

1

11

9

10

5

4

6

7

8

⑧ ⑦

⑥ ⑤

⑩ ⑪

① ②

③

④

⑨

Terminal

No.

Signalyname

Description

①

Motor/capacitor

Connectytheymotoryandycapacitor.

②

ACypoweryinputy

(L)

Single-phasey100y-y115yVyoryy

single-phasey200y-y230yV

③

NC

Notyused.y

Leaveythisyterminalyunconnected.

④

∗

1

Brakeyreleasey

inputy

∗

2

Notyanyinstantaneousystopybutyaynaturaly

stop.

ALARM-RESETy

input

ResetytheyALARMyoutput.

⑤

CCWyoperationy

inputy

∗

3

MotoryrunsyinytheyCCWydirectionyduringy

"ON."

⑥

DCypoweryinput

+24yVDCyinput

⑦

GND

GND

⑧

CWyoperationy

input

MotoryrunsyinytheyCWydirectionyduringy

"ON."

⑨

ALARMyoutputy

∗

4

Turnsy"OFF"yunderycertainyconditionsy

suchyasywhenytheymotor’sythermaly

protectorybecomesy"open."

⑩

Electromagneticy

brakey

∗

5

Connectytoytheyelectromagneticybrake.

⑪

Motor/capacitor

Connectytheymotoryandycapacitor.

*1 This signal functions as the brake release input during normal operation,

and as the ALARM-RESET input when the ALARM output is OFF.

(Refer to "Resetting an ALARM" on page 6.)

*2 Releases the electromagnetic brake for the motor with electromagnetic

brake.

*3 Not applicable to an induction motor which has four lead wires.

*4 For details, check "ALARM output" on page 6.

*5 Only for electromagnetic-brake motors.

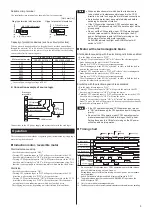

Input/outputsignals

The input/output circuits are initially set to sink logic. Switch the circuit mode

between "sink logic" and "source logic" according to the external control

equipment used. (Refer to "Switching between sink logic and source logic.")

z

Inputcircuit(internalcircuit)

The input-signal voltage is 24 VDC.

Input signals are provided as photocoupler inputs.

The signal state indicates the "ON: current supplied" or "OFF: current not

supplied" status of the internal photocoupler rather than the voltage level of

the signal.

z

Outputcircuit(internalcircuit)

Output signals are provided as open-collector outputs.

The signal state indicates the "ON: current supplied" or "OFF: current not

supplied" status of the internal transistor rather than the voltage level of the

signal.

Use a power source of 26.4 VDC or less, and limit the output current to

10 mA or less.

y

•

Connectionyexampleyofysinkylogic

DC power input

24 VDC

Brake pack

Input

䈜

4.7 k

Ω

560

Ω

䈜㻌䐦

CW operation input

㻌 䐣

CCW operation input

㻌 䐢

Brake release input

Input circuit

䐤

ALARM output

Brake pack

GND

䐧

䐥

0 V

Output circuit

2.7 k

Ω

or more

24 VDC

y

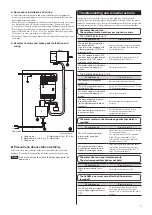

•

Connectionyexampleyofysourceylogic

24 VDC

Brake pack

䈜㻌䐦

CW operation input

㻌 䐣

CCW operation input

㻌 䐢

Brake release input

Input

GND

4.7 k

Ω

560

Ω

Input circuit

䐥

䈜

Brake pack

ALARM output

䐤

䐧

DC power input

24 VDC

Output circuit

2.7 k

Ω

or more

z

Switchingbetweensinklogicandsourcelogic

Use the sink/source selector switch on the side of the brake pack to switch the

input/output circuit mode between "sink logic" and "source logic."

In an input circuit of sink logic, a signal turns ON when current flows out of

the applicable input terminal.

In an input circuit of souce logic, a signal turns ON when current flows into

the applicable input terminal.

The factory setting is sink logic. Set an appropriate mode after confirming the

output circuit of the external control equipment to be used.

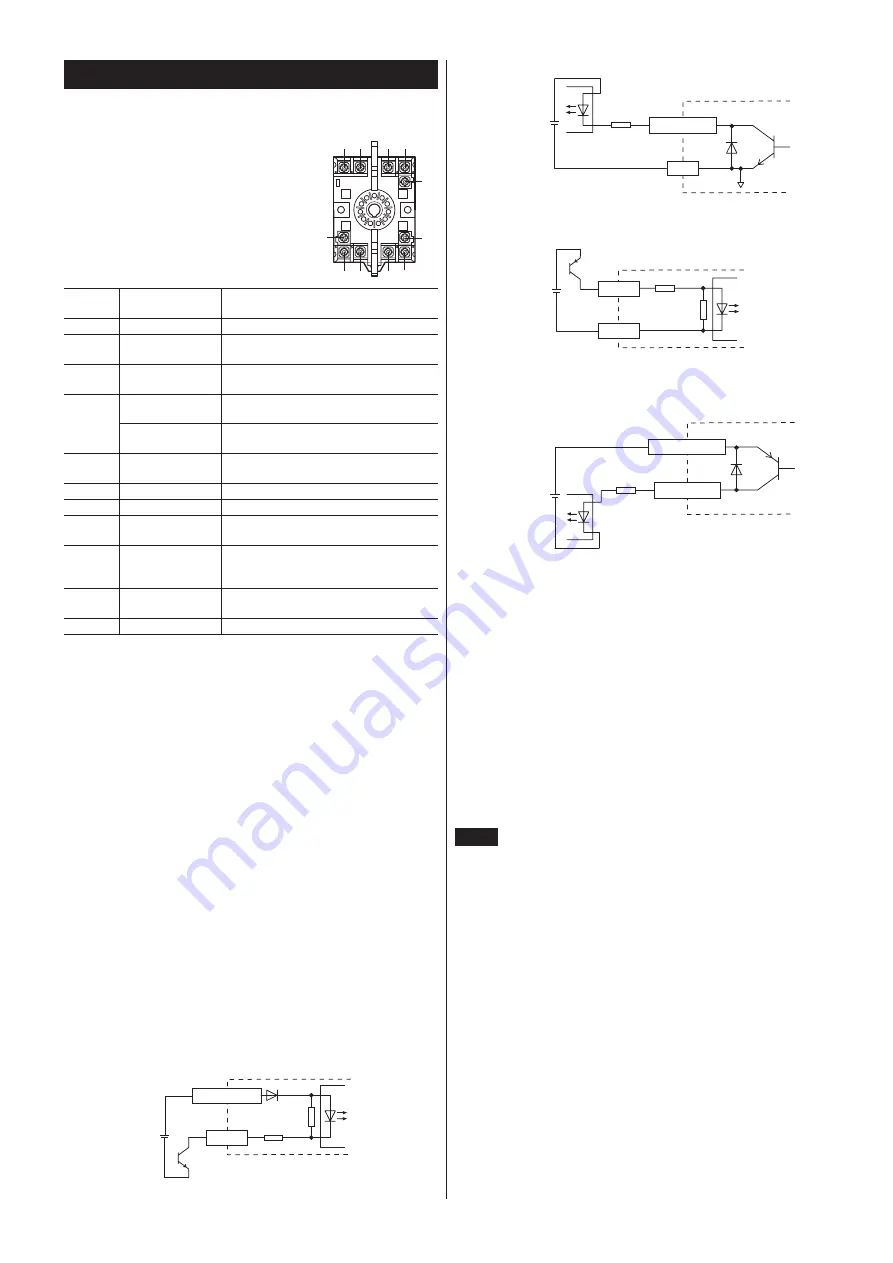

Connectionexample

The connection example of page 4 is for sink logic. See page 5, for the

connection example of source logic.

The direction of motor rotation indicates the direction as viewed from the

output-shaft side. "CW" indicates clockwise and "CCW"counterclockwise.

The direction of gear-output shaft rotation may be opposite that of motor

rotation, depending on the gear ratio of the gear head.

Note

y

•

Theyinput-signalyvoltageyisy24yVDC±10%yandy0.1yAyory

more.

y

•

Keepytheypowerylineyforytheybrakeypackyawayyfromythatyofy

noiseysourcesysuchyasyweldersyandymachinesydischargingy

electricity.

y

•

Minimizeytheylengthyofytheymotorycableyandytheyinput/outputy

signalycable.

y

•

Wireytheyinput/outputysignalycablesysoythatytheyyareyaty

leasty300ymmy(11.8yin.)yawayyfromycablesycarryingyaylargey

amountyofycurrent.yLetytheypowerycableyandymotorycabley

crossyatyay90-degreeyangleyinsteadyofyusingyparallelywiring.

y

•

UseyaycableyofyAWG18y(0.75ymm

2

)yorymoreyinydiameteryfory

theymotorycableyandypowerycable.

y

•

BeysureytoyconnectytheyGNDyterminalytoyGNDy(negativey

side)yofytheyexternalycontroller,yorytheyunitywillynotyoperate.