6

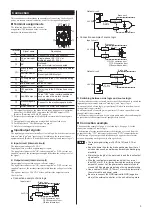

Operation/brakingrepetitivecycle

The repeated operation and braking of a motor will bring about a temperature

increase in the motor and brake pack, thereby limiting the continuous

operating time. Observe the repetitive cycle given in the table below for the

operation and braking of the motion interface.

Motoryoutput

Repetitionycycle

1ytoy25yW

2ysecondsyorymore

40ytoy90yW

4ysecondsyorymore

(Ayrepetitiveycycleyofytwoysecondsyrepresentsyoperationyforyoneysecondy

andystoppingyforyoneysecond.)

ALARMoutput

The ALARM output function of the

SB50W

monitors the motor current to

detect an actuation of the thermal protector. Accordingly, the ALARM output

function is activated in the following conditions:

y

When the built-in thermal protector of the motor was actuated

(became open).

y

When an improper connection or breakage of the power cable or motor

cable was detected.

y

When the AC power was turned on after setting an input signal to "ON."

y

When the AC power was turned off while the motor was still running or at

standstill.

When any of the above conditions occurs, the ALARM output of the

SB50W

will become "OFF" and the ALARM indicator (red) will be lit (power supply

to the motor will be cut off).

In the electromagnetic-brake type, the brake is activated in order to hold the

load in position.

∗

ALARM indicator lamp is lit momentarily when DC power is first turned on,

which is normal.

z

ResettinganALARM

BeforeyresettingyanyALARM,yremoveytheycauseyofytheyALARMy

(overheatingyofytheymotor,yetc.)yandyconfirmysafetyyaroundythey

equipment.

The brake release input functions as the brake release input during normal

operation, and as the ALARM-RESET input when the ALARM output is OFF.

Set all input signals to "OFF," and then turn the ALARM-RESET input ON for

at least 0.5 second. To restart the operation, turn the ALARM-RESET input

OFF and wait for at least 0.5 second.

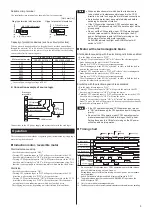

Brake release input

/

ALARM-RESET input

ALARM output

0.5 s

or more

ON or OFF

0.5 s

or more

ON or OFF

Brake release

input

ALARM-RESET

input

Brake release

input

ON

ON

ALARM reset

0.5 s or less

Turns

OFF when an

ALARM is generated.

Occurrence of ALARM

ON

ALARMs can also be reset by reconnecting the power. Turn off the DC

power and AC power, set all input signals to "OFF," and then turn the power

back on.

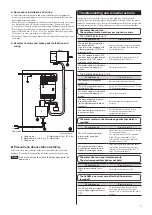

Limiting resistance

2.7 k

Ω

or more

24 VDC

External controller

Brake pack

GND

ALARM output

⑦

⑨

Photocoupler

Use a power source of 26.4 VDC or less, and limit the output current to

10 mA or less.

Installingandwiringincompliancewith

EMCDirective

General

z

EMCDirective

The brake pack has been designed and manufactured for incorporation in

general industrial machinery. The EMC Directive requires that the equipment

incorporating this product comply with these directives.

The installation and wiring method for the motor and brake pack are the

basic methods that would effectively allow the customer’s equipment to be

compliant with the EMC Directive.

The compliance of the final machinery with the EMC Directive will depend

on such factors as configuration, wiring, layout and risk involved in the

control-system equipment and electrical parts. It, therefore, must be verified

through EMC measures by the customer of the machinery.

z

Applicablestandards

EMI

Emission Tests

EN 61000-6-4

EMS

Immunity Tests

EN 61000-6-2

InstallingandwiringincompliancewithEMC

Directive

Effective measures must be taken against the EMI that the brake pack

may give to adjacent control-system equipment, as well as the EMS of the

brake pack itself, in order to prevent a serious functional impediment in the

machinery.

The use of the following installation and wiring methods will enable the

brake pack to be compliant with the EMC Directive (the aforementioned

compliance standards).

z

Connectingmainsfilter

Install a mains filter in the power source line in order to prevent the noise

generated within the brake pack from propagating outside via the AC input

line.

For mains filters, use the products as shown in the below chart, or an

equivalent.

SOSHINyELECTRICyCO.,LTD HF2010A-UPF,yNF2010A-UP

SchaffneryEMC

FN2070-10-06

Install the mains filter as close to the brake pack as possible, and use cable

clamps and other means to secure the input and output cables firmly to the

surface of the enclosure.

Connect the ground terminal of the mains filter to the grounding point, using

as thick and short a wire as possible.

Do not place the AC input cable (AWG18: 0.75 mm

2

or more) parallel with

the mains-filter output cable (AWG18: 0.75 mm

2

or more).

Parallel placement will reduce mains-filter effectiveness if the enclosure’s

internal noise is directly coupled to the power-supply cable by means of stray

capacitance.

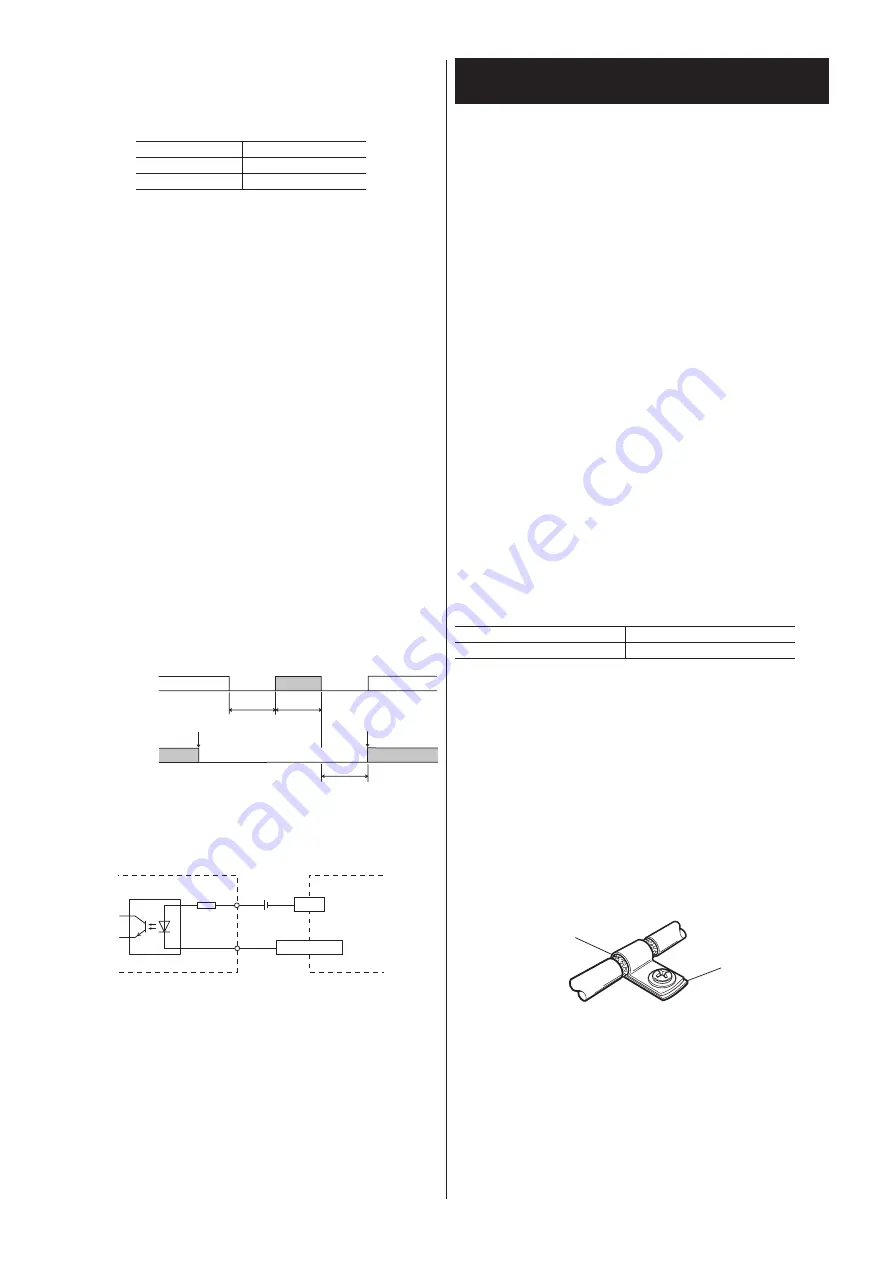

z

Wiringthesignalcable

For the signal cable for the brake pack, use a shielded cable of AWG28

(0.08 mm

2

) or more in diameter, and keep it as short as possible.

To ground a shielded cable, use a metal cable clamp or similar device that

will maintain contact with the entire circumference of the shielded cable.

Attach a cable clamp as close to the end of the cable as possible, and connect

it to an appropriate grounding point as shown in the figure.

Cable clamp

Shielded cable