7

z

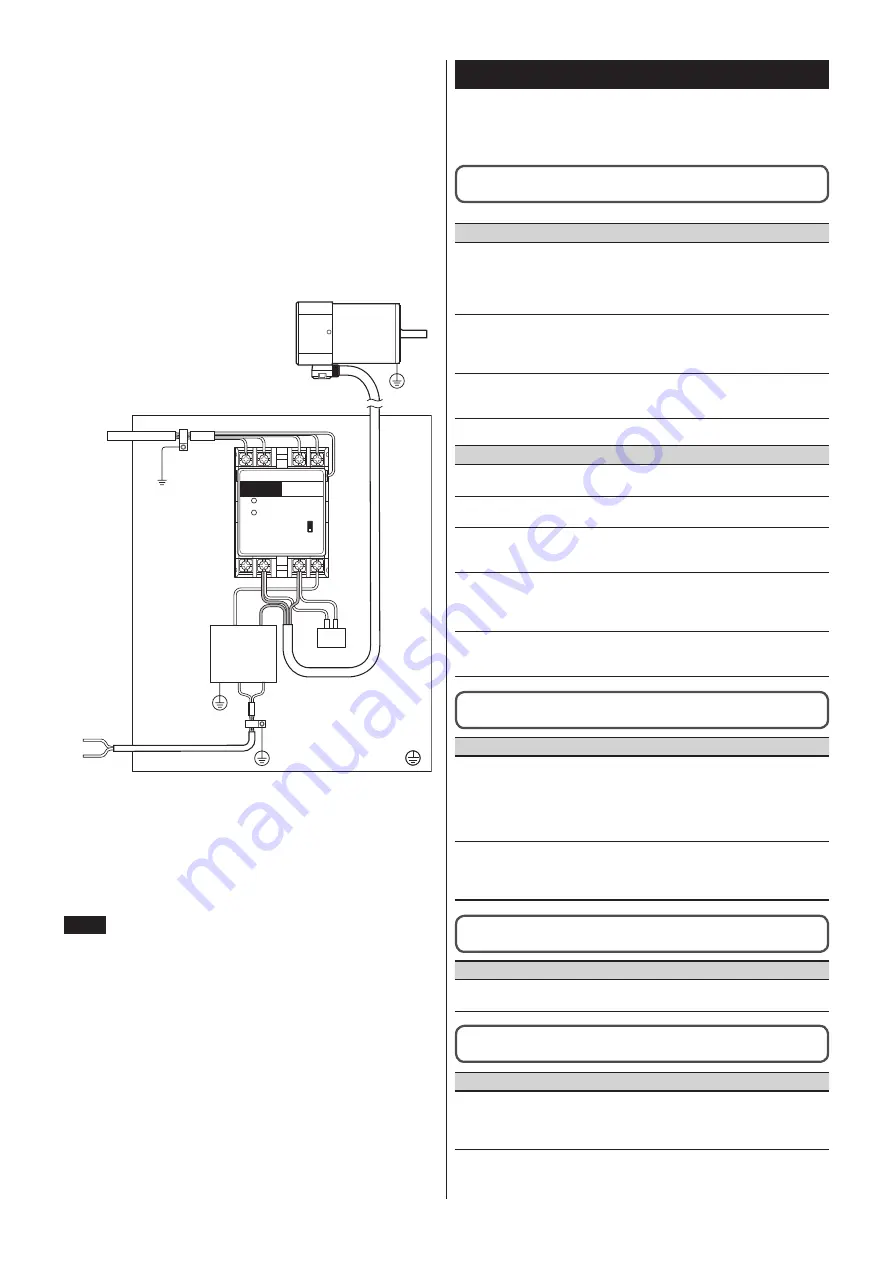

Notesaboutinstallationandwiring

y

Connect the motor/brake pack and other peripheral control equipment

directly to the grounding point so as to prevent a potential difference from

developing between grounds.

y

When relays or electromagnetic switches are used together with the system,

use mains filters and CR circuits to suppress surges generated by them.

y

Keep cables as short as possible without coiling and bundling extra lengths.

y

Place the power cables such as the motor and power-supply cables as far

apart [100 to 200 mm (3.94 to 7.87 in.)] as possible from the signal cables.

If they have to cross, cross them at a right angle.

Place the AC input cable and output cable of a mains filter separately from

each other.

z

Exampleofmotorandbrakepackinstallationand

wiring

POWER

ALARM

L

N

C

A

A

E

B

D

Motor

Capacitor

Power input

Grounded Panel

D: Motor cable [10 m (32.8 ft.)]

E: Mains filter

MODEL

SB50W

1-40W

60-90W

A: Cable clamp

B: Signal cable [2 m (6.6 ft.)]

C: Power cable

Precautionsaboutstaticelectricity

Static electricity may cause the brake pack to malfunction or become

damaged. Be careful when handling the brake pack with the power on.

Note

Doynotycomeycloseytoyorytouchytheybrakeypackywhileythey

poweryisyon.

Troubleshootingandremedialactions

During motor operation, the motor or brake pack may fail to function

properly due to an improper signal input method or wiring. When the motor

cannot be operated correctly, refer to the contents provided in this section and

take appropriate action. If the problem persists, contact your nearest office.

The motor does not run.

The number of motor rotations per minute is too low.

y

•

TheyALARMyindicatoryisylit.

Possibleycause

Remedial action

Theymotor’sythermalyprotectory

hasybeenyactuated.

(onlyyforyaymotoryequippedywithy

aythermalyprotectoryofy15yWyory

largerycapacity)

Remove the cause of motor overheating,

then reset an ALARM after the motor

TheyCWyoperationyinput,yCCWy

operationyinputyorybrakeyreleasey

inputywasysetytoy"ON"ybeforey

turningyonytheyACypower.

Set the applicable input signal to "ON"

after turning on the AC power.

Theypowerycableyorymotorycabley

isynotyconnectedyproperlyyory

broken.

Check the connection.

y

•

TheyALARMyindicatoryisynotylit.

Possibleycause

Remedial action

Theycapacitoryisyincorrectlyy

connected.

Reconnect the capacitor correctly.

CWyoryCCWyoperationyinputyisy

notyturnedytoy"ON."

Check the state or connection of CW and

CCW operation inputs.

Theypowerycableyorymotorycabley

isynotyconnectedyproperlyyory

broken.

Check the connection.

Theyelectromagneticybrakeyisy

incorrectlyyconnected.

(forytheyelectromagnetic-brakey

typeyonly)

Reconnect the electromagnetic brake

correctly.

Theysink/sourceyselectoryswitchy

isynotysetycorrectly.

Set the sink/source selector switch

according to the external control

The motor rotates in the direction opposite that which is

specified.

Possibleycause

Remedial action

CWyoryCCWyoperationyinputy

isyincorrectoryhasyaybady

connection.

Check the state or connection of CW and

CCW operation inputs.

The motor rotates in the CW direction

when CW operation input is "ON,"

and in the CCW direction when CCW

operation input is "ON."

Theygear-outputyshaftyrotatesy

inytheydirectionyoppositeymotory

rotationyatycertainygearyratios.

If the motor gear ratio makes the shaft

rotate in the direction opposite motor

rotation, reverse the operation for CW

and CCW operation inputs.

The motor does not stop instantaneously.

The electromagnetic brake does not hold.

Possibleycause

Remedial action

Brakeyreleaseyinputyisysetytoy

"ON."

Set brake release input to "OFF."

The ALARM is not reset even after the AC power was

turned off.

Possibleycause

Remedial action

TheyDCypoweryisynotyturnedyoffy

orynotyallyinputysignalsyareysetytoy

OFF.

To reset an ALARM, turn off the AC

power and DC power, set all signal

inputs to "OFF," and then turn the power

back on.