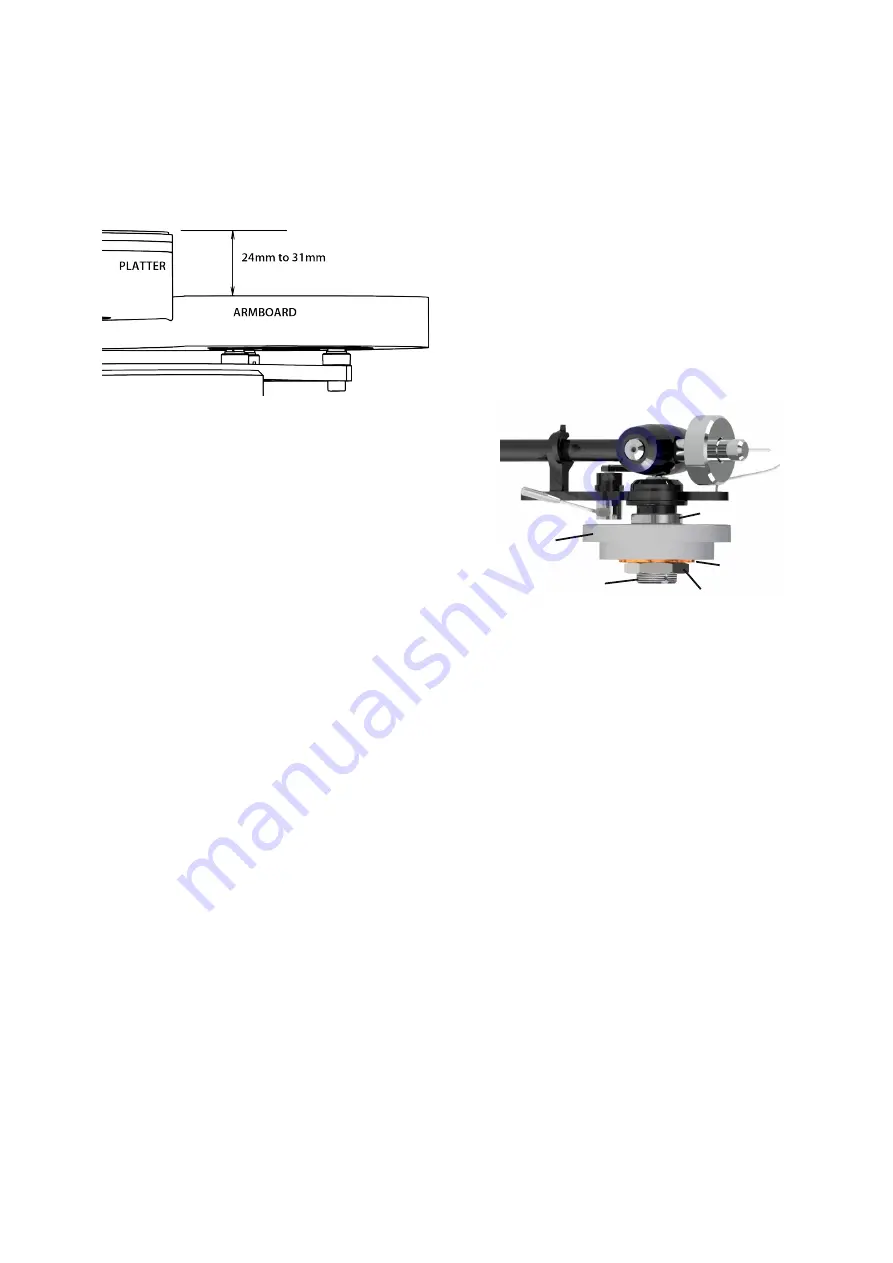

Height consideration

Origin Live arms can be raised by approx 16mm using

VTA adjustment. However performance is optimized

with the arm raised as little as possible. Ideally the

height from the top of armboard to top of platter should

be 24mm but not lower.

If this dimension is significantly larger on your deck,

you can use spacing washers – a 4mm Acrylic washer is

included for this purpose. This should be placed directly

on top of your armboard before fitting the arm.

There are other methods of adjusting armboard height

which may be advised by your turntable manufacturer.

Achieve Mounting Conditions

If your deck already has correct mounting dimensions

then skip the next section and read “Mounting the Arm”.

If your deck does not yet have the correct geometry then

alternatives are as follows.

Modify your existing armboard

You can probably modify your existing arm board to

achieve the required geometry. Please refer to our web

site – on any tonearm page see right side menu “fitting

guidance” tab.

Obtain a compatible armboard

Origin Live arm geometry is identical to that of Rega

arms. This means they are perfect drop in replacements

for all Rega arms. Many deck manufacturers cater for

mounting Rega arms and can supply you with a Rega

geometry armboard that will perfectly fit your Origin

Live arm.

If necessary ask how to fit an “old style Rega geometry,

threaded base mounting”? This is easier than the newer 3

point mount and may save you money. They should

understand what is required.

Note that although newer Rega arms have a 3 point

mounting, their armboards always have a central 24mm

diameter hole and this is all you need to mount Origin

Live arms.

If your arm has an SME mount there is an adaptor plate

available on the Origin Live website – see Accessories >

Vinyl > Adaptors

Mounting the Arm

Refer to diagram below.

1. Insert arm through mounting hole in the

armboard.

2. Fit cork washer underneath the armboard.

3. Follow this with the large clamping nut

and tighten to just finger tight.

The mistake is often made of over tightening this

nut with the result that the music sounds deadened.

Simply tighten to finger tight - as hard as you can.

If you don't have a strong grip then use a spanner,

pliers or mole grips to “nip” the nut a fraction

tighter.

CONNECT THE ARM

Fit Cable Clip

For optimal performance, support the arm cable

with a clip fastened underneath the plinth. This

helps prevent vibration feeding into the arm.

Leave a slight droop in the cable so it's not tight.

Clipping the cable is not always possible or

convenient so may be omitted.

Connect the arm to your Phono stage /

Amplifier

Plug the arm cable phono plugs into your phono

stage (amplifier). You should ensure they are a

reasonably tight fit to sockets. If this is not the case

it pays to nip the outer jaws with a pair of pliers to

close it up a little.

Earthing arrangements

Optimal earthing arrangement is largely a matter of

trial and error as it depends on your phono stage /

amplifier design. Most vinyl systems hum slightly

at high volume levels, especially valve amplifiers.

This can be reduced sometimes by changing the

earthing arrangement.

Some of our external tonearm leads have a different

number of earth leads so please read the section

Page 2

ARMBOARD

CLAMPING NUT

VTA ADJUSTER RING

CORK WASHER

THREADED BASE