Page 5

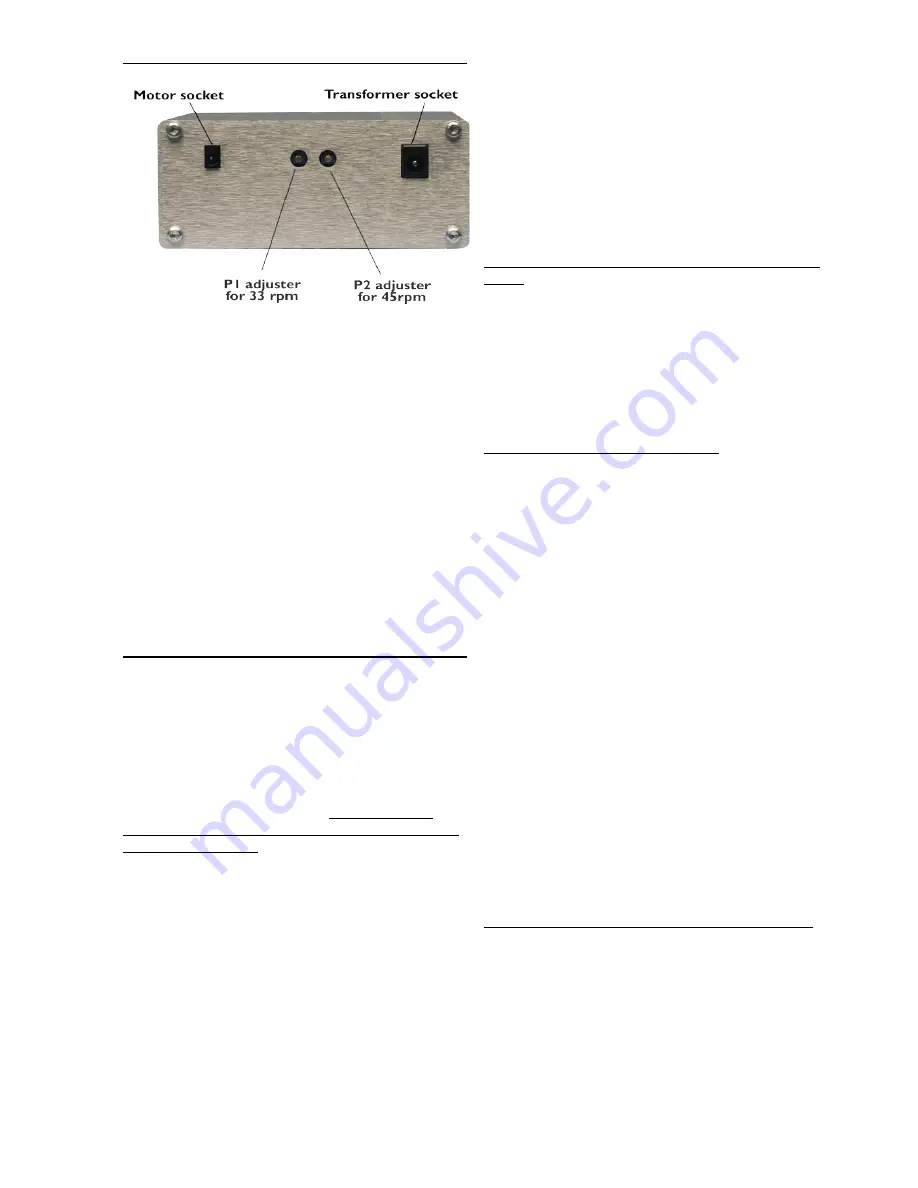

C O N N E C T T H E M O T O R D R I V E .

Plug in the black control box (switch box), transformer and

motor. The LED on the switch box will come on. This light

will remain lit all the time that the switch box is plugged in at

the mains supply.

Do not plug the transformer into mains conditioners,

filters or anything with surge protection - this is

disasterous to performance.

The location of the control box should preferably be

kept away from strong electromagnetic fields such as

those generated by transformers, amplifiers, power

supplies etc.

It is best to unplug the transformer if the switch box

is disconnected from it.

S E T T I N G T H E M O T O R S P E E D

NOTE:

You will need to set the motor speed yourself. In the first 4 hours of use

from starting up the motor, the speed tends to drift but then settles down

permanently. To burn in the regulator board components we recommend at

least 4 hours of running the motor before you accurately set the speed.

The thin output wires from the transformer only carry 8

volts and are therefore safe to handle. Voltages inside the

transformer are dangerous so the transformer case should not

be unscrewed or opened.

When the rotary switch on the control box is turned fully

anti-clockwise the motor is off.

One click of the switch clockwise is 33.3 rpm - The

second click clockwise is 45rpm

NOTE: The speed should only be finally set or checked with

the cartridge dragging on a centre track of a record as the drag

affects speed setting.

I N S T R U C T I O N S F O R R E A D I N G T H E

S T R O B E

Place the strobe disc on the record to be played. Play the record

and watch the relevant ring on the disc. Adjust the speed

until marks on the ring appear stationary while the record is

rotating. It sometimes helps to stare at infinity whilst doing

this as the marks become easier to see. You can see the strobe

effect in florescent light, although an ordinary bulb held about

2 feet from the strobe disc will also work fine. The bulb flickers

at 50 Hz in the EEC and 60 Hz in the USA.

You can purchase bayonet fitting florescent bulbs to fit normal

lamps. Try to shut out daylight when carrying out speed

setting.

S E T T H E S P E E D

Set the switch on the control box to the first click i.e. 33 rpm

setting. Adjust the motor speed as follows: using a small

flat blade screwdriver, turn the screw of P1 for 33 rpm.

The screws are accessible at the rear of the control box (See

diagram above). To increase speed, turn the 25 turn presets

clockwise until the speed changes. If the screw reaches the end

of it’s travel you can usually hear a faint clicking. You will not

damage the preset by over turning it as slippage occurs. The

pre-set screw will not fall out and may need a fair number of

turns to set the correct speed so keep turning.

Set P1 so that the platter turns at 33.3rpm. When setting the

speed, place the arm on the centre track of a record so that

the cartridge is tracking the grooves this ensures that the drag

of the cartridge is taken into account. Speed variations of up

to plus or minus 2% are quite common on decks and the dc

motor is capable of plus or minus 0.1% accuracy. Use the

strobe disc provided to set the speed (full instructions are on

the card).

However if you have problems using the strobe card,

then count the rpm using the following method. Counting

the 33.3 revs per minute is best accomplished by placing

a small piece of sticky tape on the perimeter of the platter

and then counting 100 revolutions. 33.3 rpm is exactly 100

revolutions completed in 3 minutes. To save time in the early

stages it is easiest to count 50 revs in 1 minute 30 seconds (or

25 revs in 45 seconds) and save the 100 count for the final

check.

Please note the following points when setting the speed.

Firstly all the figures below are based on setting the speed on

the deck using the centre track and letting the deck play for

a good 5 minutes beforehand with the stylus on the record

so that the whole system has settled down. The regulators

seem to take about 5 minutes to warm up,

so speed is about

2mins 58 seconds for 100 revolutions when the system starts

from cold. In other words it is 2/180 x 100 = 1 % fast when

started from cold.

Speed variation with the dc motor can vary

minutely depending on the track played and cut of record.

Click the rotary switch to the 2nd click clockwise and set P2 so

that the platter rotates at 45 or 78 rpm (if you wish) using the

same procedure as outlined above.

The dc motors are noisy to begin with and are never

completely silent in comparison to a/c motors. This is thought

to be due to a different type of precious metal brush. Having

said this they still sound a great deal better in performance

terms. To assist “running in” you can turn the speed right

up via the control box. The motor then runs at high speed.

Allow this for approx 4 hours after removing the belt. After

the running in period reset the motor speed. The motor