Page 4

house. You can “feel” overflow when inserting the spindle, it

meets resistance at the bottom which is not a “thud” of the

spindle hitting the bottom but rather a build up of pressure of

the bearing landing on a bed of oil. By further pressing, you can

then see the oil being squeezed out at the top.

Carefully lower the platter over the spindle till it rests on the

lower flange of the platter bush (ensure mating surfaces are

clean). Once the platter is fitted over the bush it pays to spin it

slowly by hand while holding the top of the spindle stationary

with your other hand - this helps the platter to “bed down”

onto the bush and become more level.

SOVEREIGN DECK ONLY

: NOTE - On newer decks

(April 2009 onwards) the sub-platter is a “loose” fit over the

spindle and can detatch from the sub-platter.

Wipe the sub-platter spindle surface first to ensure that it

is absolutely clean and very gently insert it into the bearing

house (If the oil does not overflow when the spindle touches

the bottom then try 2 drops at a time

till you just achieve

overflow

- wipe away excess oil without withdrawing the sub-

platter. Next place the sub-platter on the spindle such that the

less recessed side is uppermost.

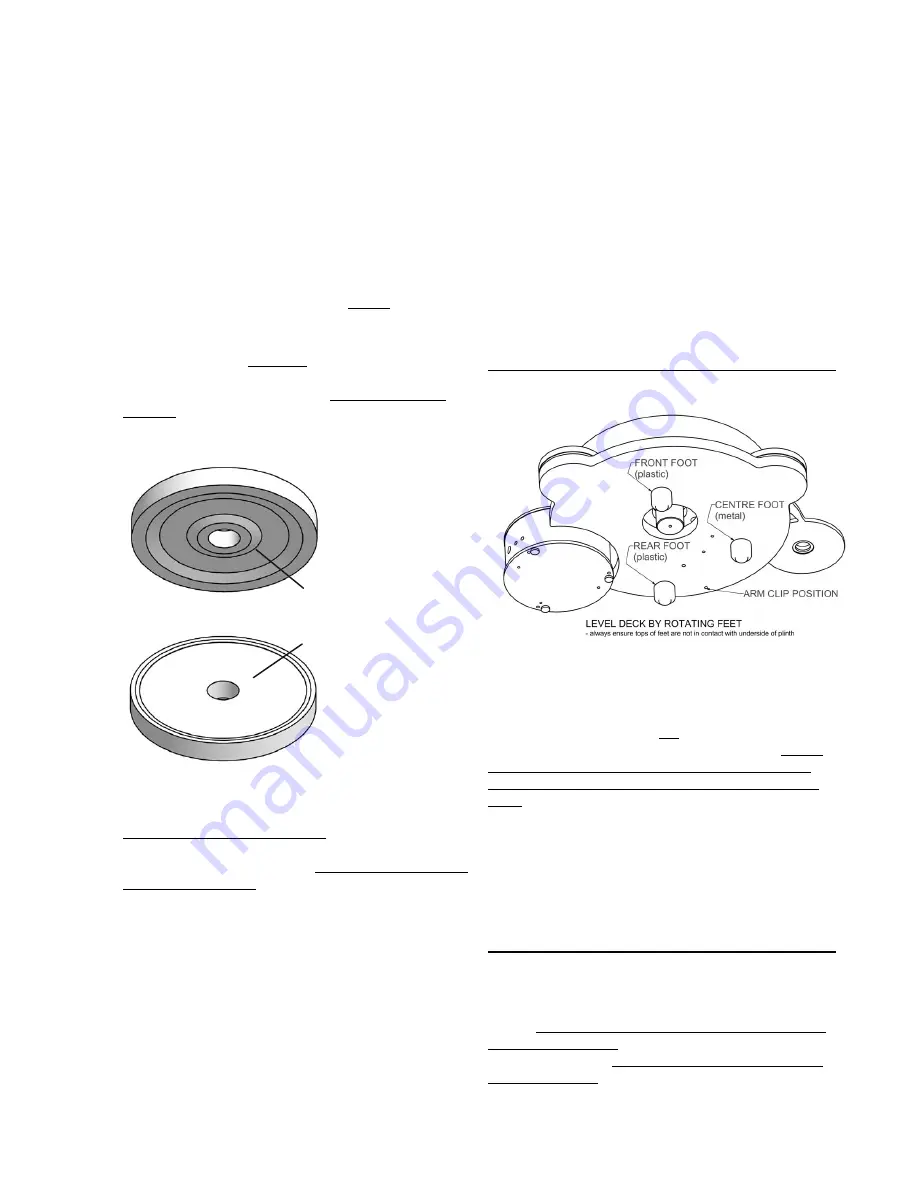

UNDERSIDE OF

SUB-PLATTER

TOPSIDE OF

SUB-PLATTER

Lastly, place the platter on top of the sub-platter and follow this

with the thin black platter mat .

If you have the heavyweight platter

then raise the plinth more

than normal by winding out the adjustable feet, till the platter

no longer fouls on the motor pod. The belt must NOT run in

the groove of the platter. Do not tighten up the allen bolts in

the underside of the platter - these sound best with minimum

tension.

NOTES:

The bearing fit is carefully toleranced to run fully loaded

with the specific oil we supply. It needs at least 10 minutes to

distribute the oil evenly over the running surfaces and approx

24 hours to properly “run in”. It needs this because of the exact

tolerances (0.0001”)which “float” the bearing off the side walls

to avoid metal to metal contact and also minimize viscous drag.

Eventually it should run virtually silent when truly vertical

and full of oil

- if it doesn’t do so, there has probably been

contamination with dust and you will need to clean it out with

a lint free paper towel or similar wrapped around a thin rod. If

you do this, be sure to also wipe the oil off the spindle as this

also may contain microscopic contamination that is not visible.

Do not use any other oil than Origin Live oil.

Do not tamper with the bolt in the bottom of the bearing

or oil leaks will occur and you will probably not succeed in

re-tightening it.

The thrust plate at the bottom of the bearing house may

appear to be discoloured or dirty - you should not attempt

to clean this up as it is part of the hardening process - the

centre of the plate is polished as this is the only part that

the spindle touches.

The Platter works best with the Origin Live platter mats but these are

not necessarily included in the lower part of the deck range - all of the

many other mats we have tried do not work on the OL decks.

L E V E L T H E D E C K

The 3 feet under the plinth are all threaded so that by rotating

them you can adjust the level of the deck - Rotate all three feet

so that the top of the foot does

not

touch the plinth and only

sits on the thread alone - this is for best performance.

At this

stage check that the bearing house is at least 1mm clear

of touching the surface your deck is standing on (Aurora

only).

Note that when you level the deck, the only thing that matters

is that the platter (not the plinth) is level. Sometimes there

may be a slight discrepancy between the level of the plinth and

platter but this does not matter and is usually imperceptible

visually.

P O S I T I O N M O T O R P O D & F I T

B E L T

Position the motor pod roughly as shown in previous diagrams.

The pod should be oriented as shown, such that the switch is at

the front. Ideally the centre of the pulley should be somewhere

between

215mm (8.45inches) to 225mm (8.9 inches)

from

the centre of the platter.

We recommend and set up the speed

at factory at 217mm

. The pod must not touch the plinth so

rotate it if necessary. Fit the belt over the platter first and then

pull it over the motor pulley taking care not to twist it.

Summary of Contents for Aurora MKII

Page 9: ...Page 9...