21

VCCX2 Controller Technical Guide

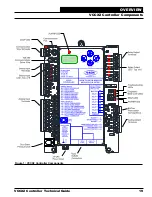

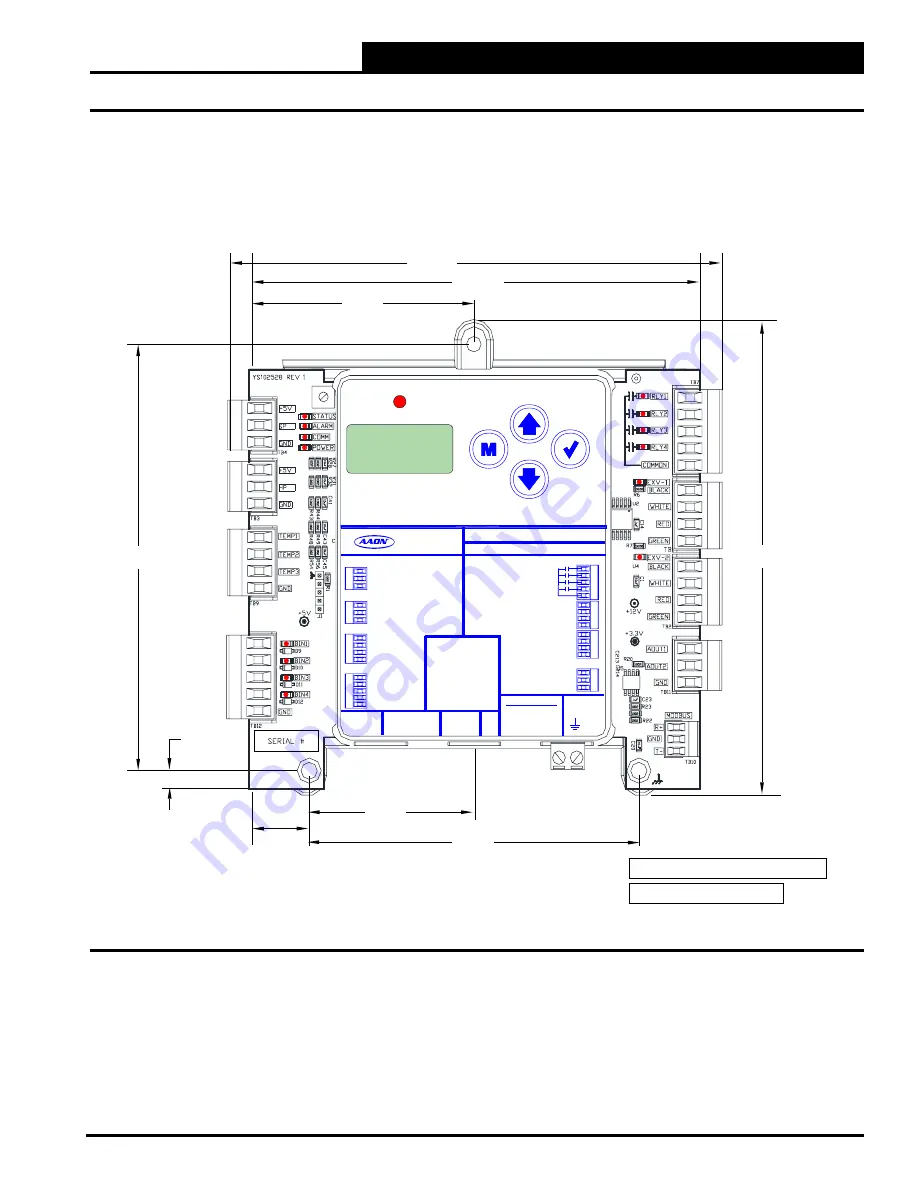

Figure 3: Typical Refrigerant System Module Dimensions (RSMV Shown)

DIMENSIONS

Refrigerant System Module (RSM)

AAON P/N: ASM01686

+24

V

A

C

GND

RELAY CONTACT

RATING IS 1 AMP

MAX @ 24 VAC

CONDENSER

COMP 1

COMP 2

ANALOG OUTPUTS

COMMON

RELAY OUTPUTS

LABEL P/N:

G042020

MOD COMP SIG

CONDENSER FAN SIG

GND

24 VAC POWER ONLY

WARNING! POLARITY

MUST BE OBSERVED

OR THE CONTROLLER

WILL BE DAMAGED

NOT USED

+5 V

+5 V

COIL TEMP 1

COMP STATUS 1

SP

HP

COIL TEMP 2

COMP STATUS 2

GND

GND

NOT USED

NOT USED

GND

TEMP 3

GND

COIL TEMP SENSORS

BINARY INPUTS

E-BUS

RSM FOR VFD COMPRESSORS

www.aaon.com

SUCTION PRESSURE SENSOR

HEAD PRESSURE SENSOR

E-BUS

EXPANSION

VALVE 1

EXPANSION

VALVE 2

WHITE

BLACK

RED

GREEN

WHITE

BLACK

RED

GREEN

ALARM

UP

DOWN

ENTER

MENU

5.00

0.20

0.57

2.05

4.10

5.63

5.24

2.62

5.73

Note:

All Dimensions are in inches.

Note:

Depth is 1.50 inches.