37

OrionWelders.com

ch

.

5/6

Electrode contamination can lead to small “explosions” that

create craters in the work piece. All four welds were made at the

same setting. Metal contamination on the electrode caused one

weld to create a crater.

It is recommended that the user pay close attention to the electrode condition (see additional

discussion) . A contaminated electrode can lead to inconsistent welds and poor arc starting . Only

light pressure is needed to start the welding process, too much pressure will interfere with the

welding process, lead to electrode metal contamination and will shorten the amount of time you

can weld before re-sharpening or replacing the electrode .

CHAPTER 6: TECHNIQUES, TIPS, & TRICKS

Pulse Arc Welding: Adding Material

Typically material is added with a small “laser” wire, one weld at a time . However, there are many

additional options to add material . One for example is, instead of using small “laser wire” the

Orion can weld a much larger wire or rod to fill in more metal in a single weld . There are several

methods to aid in the addition of fill wire, which are mentioned below . The placement of the

electrode relative to the wire is very important and will influence how the material behaves during

the addition process .

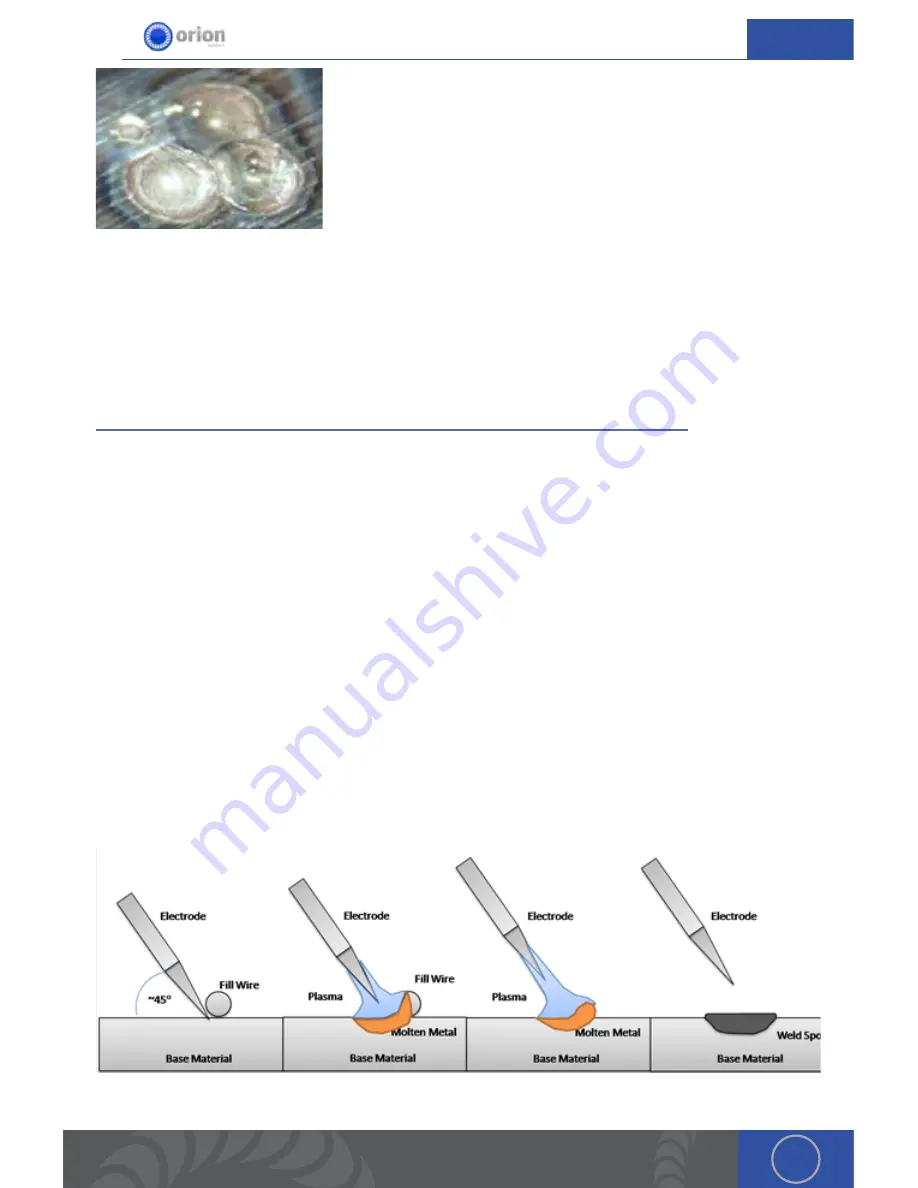

SIDE PLACEMENT:

Placing the electrode on the side of the wire is generally the best method of

adding fill wire . As shown below, place the electrode at an approximate 45 degree angle between

the wire and the base material . As the electrode pulls away from the base material and the arc

ignition happens, the base material will melt first and then the wire will be melted and pushed

or pulled (by surface tension) into the base material . This is an excellent method to produce a

uniform molten pool of metal and ensure the proper mixing of the base material and the fill wire .

The electrode may also be placed at a 45 degree angle in front of the wire . However, less material

will be added with every weld, and a portion of the wire will typically ball-up in the process .