10

Push the washer up on the bolt as far as you can with your

fingers

(Figure 8a).

Then place the insertion tube on the

bolt

(Figure 8b)

and use it to push the washer farther up

on the bolt, into the counterbored hole in the wood

(Fig-

ure 8c).

The washer will keep the bolt captive when it is

fully disengaged from the mating part of the base.

Repeat this procedure for the other five connecting bolts

to be installed in the front panel, and for the six addition-

al connecting bolts that attach the side panels and side

braces to the top baseplate.

Now attach the front brace (B) to the two side panels (C)

4.

with the four appropriate captive connecting bolts. Use

the hand knob to screw each bolt into the threaded metal

receptacle recessed in the side panel. The side panels

should be oriented so the side braces are facing outward.

The front panel should be oriented so that the metal insert

(Figure 5,

top

)

faces inward. Do not completely tighten

the connecting bolts yet.

Place the assembled side panel/front panel structure on

5.

the top baseplate (D), aligning as best you can the pro-

truding connecting bolts with the holes in the baseplate.

The baseplate should be oriented so that the Ebony Star

azimuth bearing ring is facing downward. Turn the con-

necting bolt hand knobs to fasten the side panel/front

panel structure to the baseplate.

Firmly tighten all 12 connecting bolts installed in steps

6.

4 and 5. Again, do not overtighten to avoid stripping the

threads.

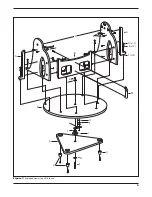

The azimuth encoder board (E) attaches to the underside

7.

of the top baseplate (D). Insert an encoder wood screw

through the slotted hole in the azimuth encoder board so

that the head of the screw is on the side of the encoder

board without the modular connector. Now, place the two

thick (P) and one thin (O) azimuth encoder spacer wash-

ers on the screw

(Figure 9).

These washers are critical in

providing the proper spacing for the assembled azimuth

encoder. The two thick azimuth encoder spacer washers

are included with the base, but the thin azimuth encoder

spacer washer is included with the IntelliScope Object

Locator kit.

Insert the modular jack on the azimuth encoder board (E)

8.

into the rectangular cutout in the top baseplate (D) and

align the encoder board so the screw lines up with the

pre-drilled pilot hole in the baseplate, and the large hole

in the encoder board lines up with the central hole in the

baseplate (

Figure 9

). Thread the encoder wood screw

(with spacer washers attached) into the pilot hole with a

Phillips screwdriver and tighten until just tight.

Note: After the azimuth encoder board is installed to the bot-

tom of the top baseplate, do not rest the baseplate on the

ground, or the encoder board could be damaged. At this

stage, rest the partially assembled base on its side.

Position the ground baseplate (A) so that it is standing

9.

on its feet. Place one fender washer (H) onto the azimuth

axis bolt (I), then insert the bolt up through the hole in the

ground baseplate. Now temporarily place a piece of duct

tape, masking tape, or packing tape over the head of the

azimuth axis bolt

(Figure 10).

This will keep the bolt from

sliding downward as you install the top baseplate, which

you will do in step 11.

Place the azimuth encoder disk (J), flat side down, over

10.

the azimuth axis bolt (I) and onto the ground baseplate

(A). Then place the brass azimuth bushing (F) onto the

azimuth axis bolt (I) so the wide end of the bushing is

closest to the encoder disk (J). Seat the bushing onto the

Figure 8. (a)

Place a rubber washer on the threaded end of the

connecting bolt and push it on as far as you can with your fingers.

(b)

Then use the included insertion tube to push the washer past the

threads on the bolt and up into the counterbored hole in the wood.

Figure 9.

To install the azimuth encoder board, insert an encoder

board mounting screw through the slotted hole in the board. Then,

add two thick and one thin encoder spacing washers onto the screw.

Now, insert the modular connector on the encoder board into the

square hole in the top baseplate, and thread the screw into the pilot

hole using a Phillips head screwdriver.

Azimuth encoder

spacer washers,

thick (2x)

Pilot hole

Azimuth encoder

spacer washer, thin

Encoder

wood

screw

Azimuth

encoder

board

Top baseplate

Connecting bolt

hand knob

Rubber

washer

Spacer

Insertion tube

Washer

recessed

a.

b.

c.