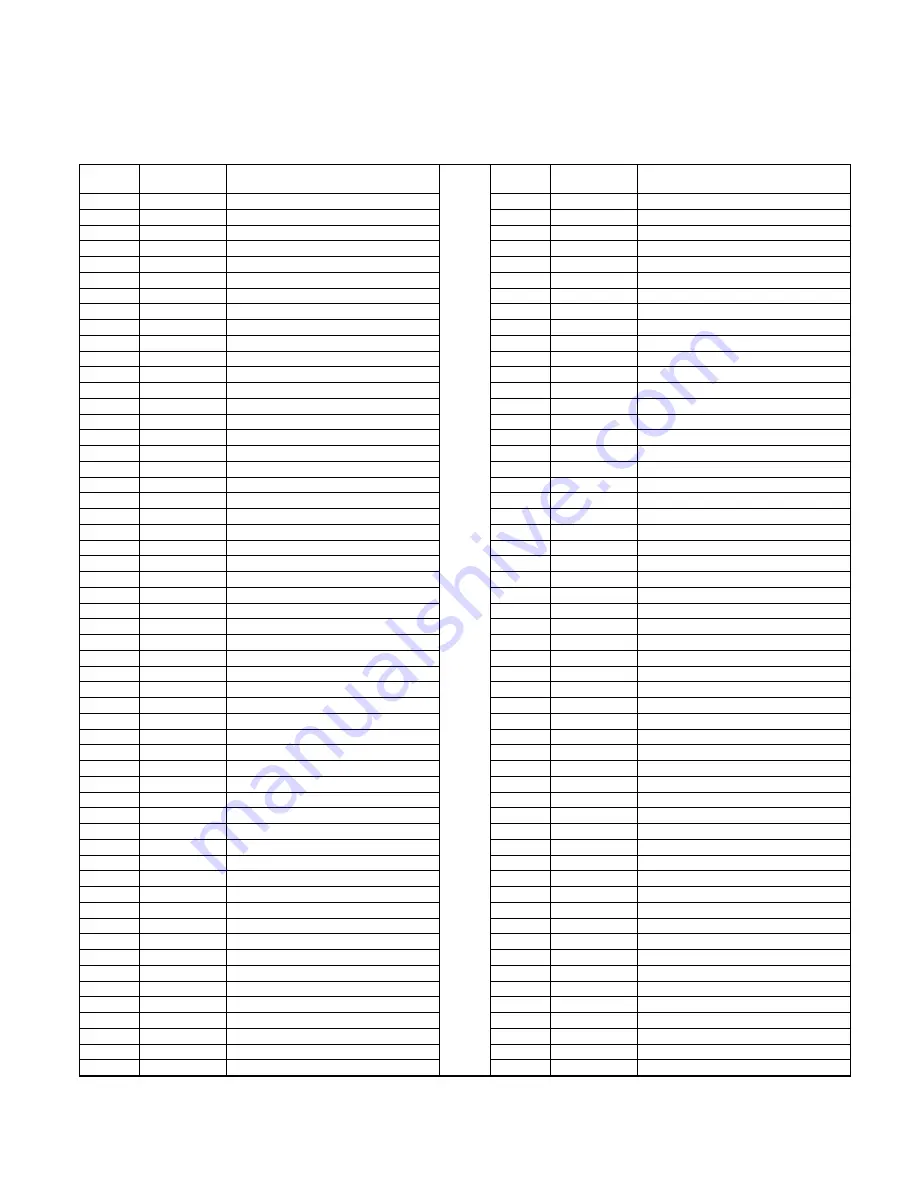

PARTS LIST-CN565B

NO.

CODE

Description

NO.

CODE

Description

1

610560

BOLT M6X20

57

510220

O-RING 6.7X1.8

2

320940

BUSHING

58

330010

TRIGGER VALVE BUSHING

3

410280

EXHAUST COVER

59

512080

O-RING 5.5X2

4

320930

EXHAUST FILTER (A)

60

420640

PIN CAP ©

5

320920

EXHAUST FILTER (B)

61

320800

STEP PIN

6

110210

CYLINDER CAP

62

620390

FEED SPRING

7

610230

BOLT M6X30

63

320960

CHECK TOE

8

320910

SIDE PROTECTOR

64

420170

PIN CAP (A)

9

320900

PISTON STOP SEAT

65

210210

FEED PAWL

10

410270

PISTON STOP

66

320780

FEED PAWL PIN

11

320890

WASHER

67

110220

NOSE

12

620380

COMPRESSION SPRING

68

320850

DOOR PIN

13

420610

HEAD VALVE PISTON

69

420630

DUST COVER

14

510710

O-RING 54X3.1

70

420620

GUARD COVER

15

510560

O-RING 41.2X2.65

71

210250

DOOR

16

410260

HEAD VALVE SLEEVE

72

420160

PIN CAP (B)

17

410250

BUMPER

73

210230

CHECK PAWL (A)

18

520130

CYLINDER SEAL

74

620300

CHECK SPRING (A)

19

511010

O-RING 63.8X3.1

75

620070

CHECK SPRING (B)

20

510680

O-RING 50X2.65

76

210240

CHECK PAWL (B)

21

310180

CYLINDER

77

320950

CHECK PAWL PIN

22

420600

CYLINDER RING

78

610110

BOLT M5X22

23

110200

BODY

79

210270

LATCH

24

640180

ROLL PIN 3X30

80

620430

LATCH SPRING

25

410460

HANDLE GRIP

81

320990

STEP PIN

26

323220

DOWEL PIN

82

610320

NUT M5(Nylock)

27

620370

SPRING

83

510640

O-RING 47.5X1.8

28

110190

ADJUST BUTTON

84

610220

BOLT M6X25(Loctite)

29

320880

CONTACT PLATE

85

510260

O-RING 9X1.8

30

420590

TRIGGER BRACKET

86

620340

SPRING

31

420580

TRIGGER

87

320770

FEED PISTON

32

321810

STEP PIN

88

510390

O-RING 17X2.65

33

420950

PIN CAP

89

620420

FEED PISTON SPRING (A)

34

510220

O-RING 6.7X1.8

90

620410

FEED PISTON SPRING (B)

35

321740

SAFETY UPPER

91

410240

FEED PISTON BUMPER

36

620670

SPRING

92

320760

FEED PISTON CAP

37

420560

SAFETY UPPER GUIDE

93

630080

SNAP RING 24

38

640020

ROLL PIN 2.5X10

94

410290

NOSE CAP

39

421080

ADJUST DIAL

95

110310

END CAP

40

420650

SAFETY GUIDE

96

420540

FILTER

41

323120

SAFETY

97

630110

SNAP RING 32

42

320980

DRIVE BLADE (Loctite)

98

420240

SPRING HOLDER (B)

43

310190

PISTON

99

421570

MAGAZINE

44

510510

O-RING 37.5X3.55

100

610130

BOLT M5X30

45

620910

SNAP RING 4

101

321890

WASHER

46

510140

O-RING 5.15X1.8

102

320260

MAGAZINE PIN

47

320970

ADJUSTER

103

620650

MAGAZINE SPRING

48

640250

STRAIGHT PIN B3X15

104

420210

NAIL SUPPORT PLATE

49

510410

O-RING 18.3X2.65

105

420520

SPRING HOLDER (A)

50

420090

TRIGGER VALVE CAGE

106

420530

MAGAZINE COVER

51

512070

O-RING 15.8X1.9

107

620740

SPRING

52

420080

TIGGER VALVE CAP

108

520290

GASKET

53

320110

TIGGER STEM

111

410060

RUBBER BUTTON

54

510030

O-RING 2.5X1.4

112

630190

SNAP RING 3

55

620050

SPRING

P1

D320981

DRIVER UNIT

56

510240

O-RING 8.6X1.9

P2

T420091

TRIGGER VALVE

Summary of Contents for CN565B

Page 13: ...TOOL SCHEMATIC CN565B ...