Machine Manual

Orion

Flex Stretchwrapper

Revision 3.0

Troubleshooting

15 February 2016

Page 4-8

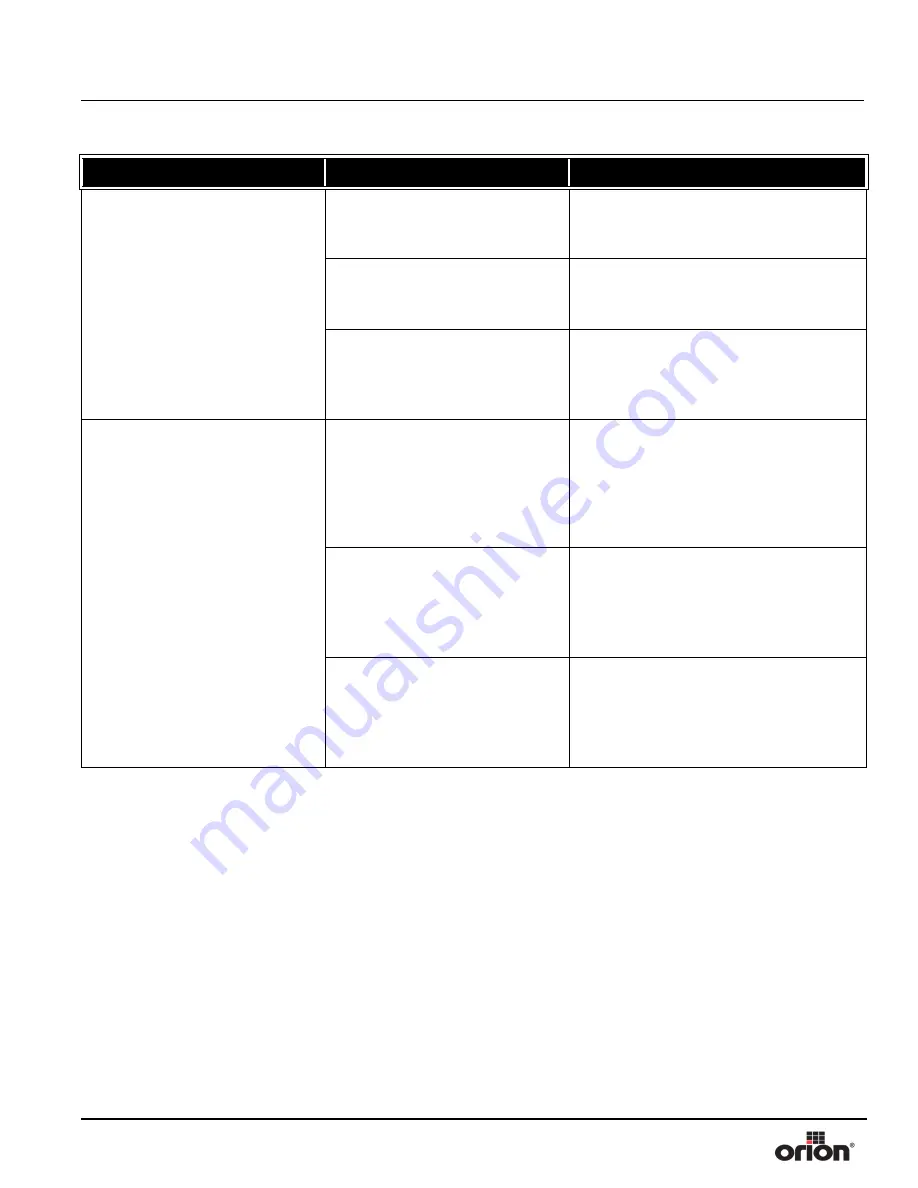

Carriage Lift

(Up & Down)

Carriage Will Not Move Up Or

Down (In Either Manual Mode

Or During An Auto Wrap

Cycle)

Blown Fuse.

Locate carriage lift control fuse. Remove

fuse and check continuity.

Bad Fuse? Replace with correct type.

Motor failure.

Perform motor test per motor manufac-

turer's recommendation.

Replace Motor as needed.

Reducer failure.

Remove Carriage Lift reducer-separate

motor from reducer. Rotate input shaft and

check for binding

Replace reducer as needed.

Carriage Will Not Move Up Or

Down

(In Auto Wrap Cycle Only-but

Works Fine In Manual Mode).

Auto-height photocell positioned

incorrectly.

Check the position of the Auto-height

photocell. Make sure it is aimed at the

load. If the load is too short for the photo-

cell to see, the carriage will not move up-

this is normal.

Re-Aim the photocell correctly.

Auto-height sensor has failed.

Check for 24VDC at the sensor. Check for

24VDC switching on the return wire to

PLC at the sensor.

No VDC Switching out at the sensor?

Replace sensor.

Wiring in the Auto-height sensor

circuit has failed.

Run a continuity test on wiring from the

sensor to the PLC and 24VDC supply

rails.

No continuity on any wire?= repair or

replace wiring.

Table 4-1. Troubleshooting Chart (Continued)

PROBLEM

POSSIBLE CAUSE

SOLUTION

Summary of Contents for FLEX HPA

Page 120: ...Machine Manual Orion Flex Stretchwrapper Revision 3 0 Maintenance 15 February 2016 Page 5 10...

Page 124: ......

Page 125: ......

Page 126: ......

Page 127: ......

Page 128: ......

Page 129: ......

Page 130: ......

Page 131: ......

Page 132: ......

Page 133: ......

Page 134: ...G R...

Page 135: ......

Page 136: ......

Page 137: ......

Page 138: ......

Page 139: ......

Page 140: ......

Page 141: ......

Page 142: ......

Page 143: ......

Page 144: ......

Page 145: ......

Page 146: ......

Page 147: ......

Page 148: ...G R...

Page 149: ......

Page 150: ......

Page 151: ......

Page 152: ......

Page 153: ......

Page 154: ......

Page 155: ......

Page 156: ......

Page 157: ......

Page 158: ......

Page 159: ......

Page 160: ......

Page 161: ......

Page 162: ...G R...

Page 163: ......

Page 164: ......

Page 165: ......