5

2. assembly

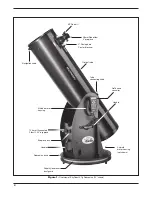

Now that you have unpacked the boxes and familiarized

yourself with all the parts in front of you, it is time to begin

assembly.

assembly of the Dobsonian Base

The base need only be assembled once, unless you disas-

semble it for long-term storage. The assembly process should

take about half an hour. All necessary tools are included in

the packages. The two ground baseplates arrive preassem-

bled with the motors, optical encoders, and motor housings

installed. There is a protective strip of polyethylene foam

material between the two base plates

(Figure 5). Do not

attempt to remove this material; it is glued in place. It is

designed to keep dust out of the azimuth motor assembly

and gears.

During initial assembly it is suggested to fasten the screws

just enough to hold the panels together loosely. When all of

the components are assembled, then perform the final tight-

ening of each screw one or two turns at a time, alternating

from one screw to the next to ensure all are tightened evenly.

When tightening screws, tighten them until firm, but be careful

not to strip the holes by over-tightening.

1. Turn the baseplate assembly upside-down and gently

rest it on the azimuth motor housing. Locate the three

starter holes on the perimeter of the bottom baseplate

(Figure 6). Insert the screws through the feet and thread

them into the predrilled starter holes

(Figure 7) with the

supplied Phillips screwdriver until tight.

2. Connect the side panels to the front panel

(Figure 8).

Use the coarse thread socket-head screws for this. There

are unthreaded pilot holes (without the metal collar) to

align these pieces. Orient the side panels so the oval

XTg label is facing outward. Orient the front panel so that

the pilot holes for the handle and eyepiece rack face out.

The side panel with the motor attached is the left panel.

There are six screws total (three for each side) to assem-

ble. Start by inserting the screws and turning by hand

to ensure they are going in straight. When you begin to

meet resistance use the 4mm hex key to complete this

step. Do not completely tighten the screws yet. Having

the boards a little loose will help in aligning the assembly

to the top baseplate in step 3. The completed assembly

should look like

Figure 9.

2a. [For XT12g only] Attach a side brace to the outside sur-

face of both the left and right side panels. Each side brace

is attached with three base assembly wood screws. Insert

the screws through the corresponding pre-drilled holes in

the side panel and then thread them into the brace using

the included 4mm hex key.

Figure 7.

Attaching the base feet to the base.

Figure 8.

Secure the front panel to each side panel.

Figure 9.

The completed side panel and front panel assembly

(XT10g shown).