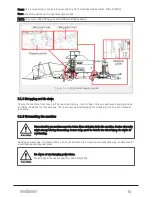

4.2.10 Oil temperature

The oil temperature is shown in the top left corner on the display unit main page. If the oil is too cold, run

the PTO at maximum 300 rpm until the minimum start temperature is reached. See temperature values

below.

IMPORTANT: Starting the PTO drive shaft with full speed at a too low temperature may harm the hydraulic sys-

tem.

Heating the oil may take up to 25 minutes. A sticker on the oil tank indicates the applied oil type.

IMPORTANT: Run the PTO at 300 rpm until the minimum start temperature is reached.

Titan Transway WB: Minimum start temperature: 5°C / 50°F When the minimum start temperature is

reached, increase the PTO speed to 850 rpm.

4.2.11 Stairs

Unfold: The compactor is equipped with foldable stairs. The stair may be unfolded to working position as fol-

lows:

1. Pull the lever towards you and pull the stairs out from the machine until the support is fully exten-

ded.

2. Push the lever away from yourself and carefully fold the lower part of the stairs outwards and down.

Fold: The stair may be folded back into transport position as follows:

1. Carefully fold the lower part of the stairs upwards and in. Ensure that the lock engages.

2. Hold the upper stair segment and fold the middle of the support upwards and in. Ensure that the

lock engages.

Ensure that the stairs are properly locked before transporting the machine.

4.3 DAILY CHECKLIST

4.3.1 Daily checklist prior to startup

No Checkpoint prior to startup

1

Ensure that the drawbar is set in operational position.

2

Check that all main valves are open.

3

Check chain oil and grease level.

4

Check if grease comes out from the pressure relief valve on the grease pump unit (indicates blocking of

pipe).

5

Check the tension of chains, carrier belts, and chamber belts.

6

Check wrapping table sensors and table movement.

7

Leave the wrapping table in its middle position.

8

Look for oil leaks.

9

Check the oil temperature.

10 Check the levelling of the machine.

4 OPERATION

42

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...