Figure 4.3 :

Filters

IMPORTANT:

Orkel recommends that the operator regularly performs visual controls of the compactor as well as act-

ive listening for abnormal noises. Perform adjustments as soon as there is a need. A problem that is not

immediately rectified may cause further problems, and in worst case lead to mechanical breakdown.

No Checkpoints during and after break-in period

1

Grease collar. Check that all bearings have grease collar.

2

Perform visual control of the compactor – before, during and after use.

3

Grease pump. Check pressure relief valve, no visible grease shall be present.

4

Elevator chain. Check tension after 1-3 hours of operation

5

Check and adjust elevator and sensor.

6

Replace filters after the first 50 hours of operation.

7

Change hydraulic oil after 50 hours of operation.

8

Listen for abnormal noises.

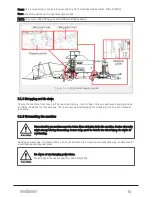

4.5 AUTOMATIC OPERATION

IMPORTANT: If the tank valves are closed when the PTO is started, there is a high risk of damaging the

hydraulic system. Before starting, please make sure that all tank valves are open. See

4 OPERATION

44

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...