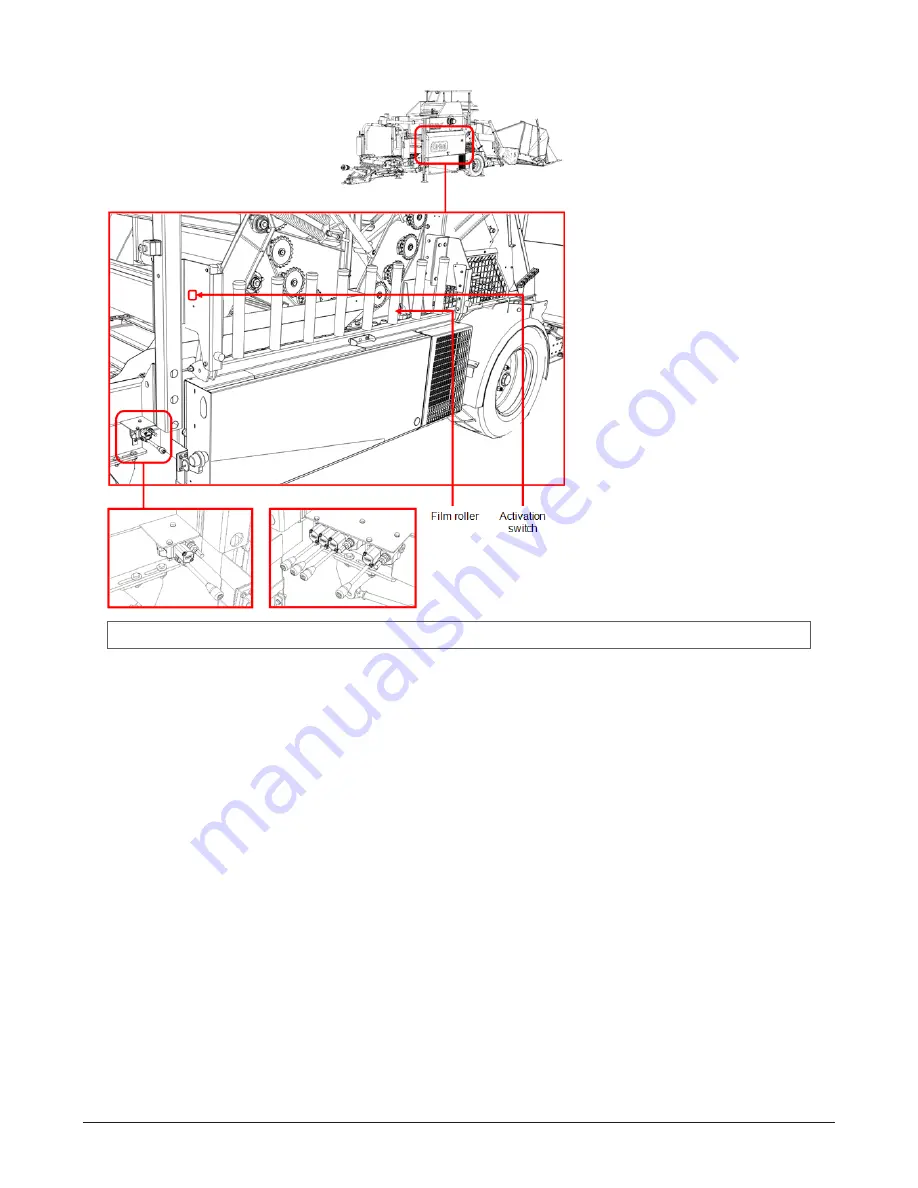

age. In order to operate the storages the machine must be connected to the tractor’s hydraulic system,

with the oil flow activated. The total capacity is 15 film rollers.

NOTE: 14 turns/laps of the wrapping arm equals approximately 6 layers of film on the bale.

4.7 WRAPPING ARMS

4.7.1 Wrapping arm emergency stop

The compactors wrapping arms are equipped with safety guards that stop the wrappers movement if

obstructed while wrapping. If the safety guards are triggered, there will be a popup message on the dis-

play unit. The safety guards must be manually cleared from any obstruction. The machine will not start

until activated by a new command from the display unit.

4.7.2 Installing a new film roller in the wrapper

1. Grab the tensioner on the stretcher and pull it to the right.

2. Open the lock lever, lift the centering cone and lock it in its upper position.

3. Replace the empty film roller.

4. Align the film roller with the centering cone, drop and lock the cone.

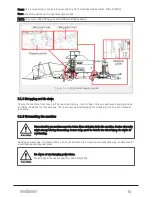

5. Thread the film as shown on

and swing back the tensioner onto the film roller.

6. Fasten the film on the bale or the film cutter. Wrapping may now continue.

4 OPERATION

46

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...