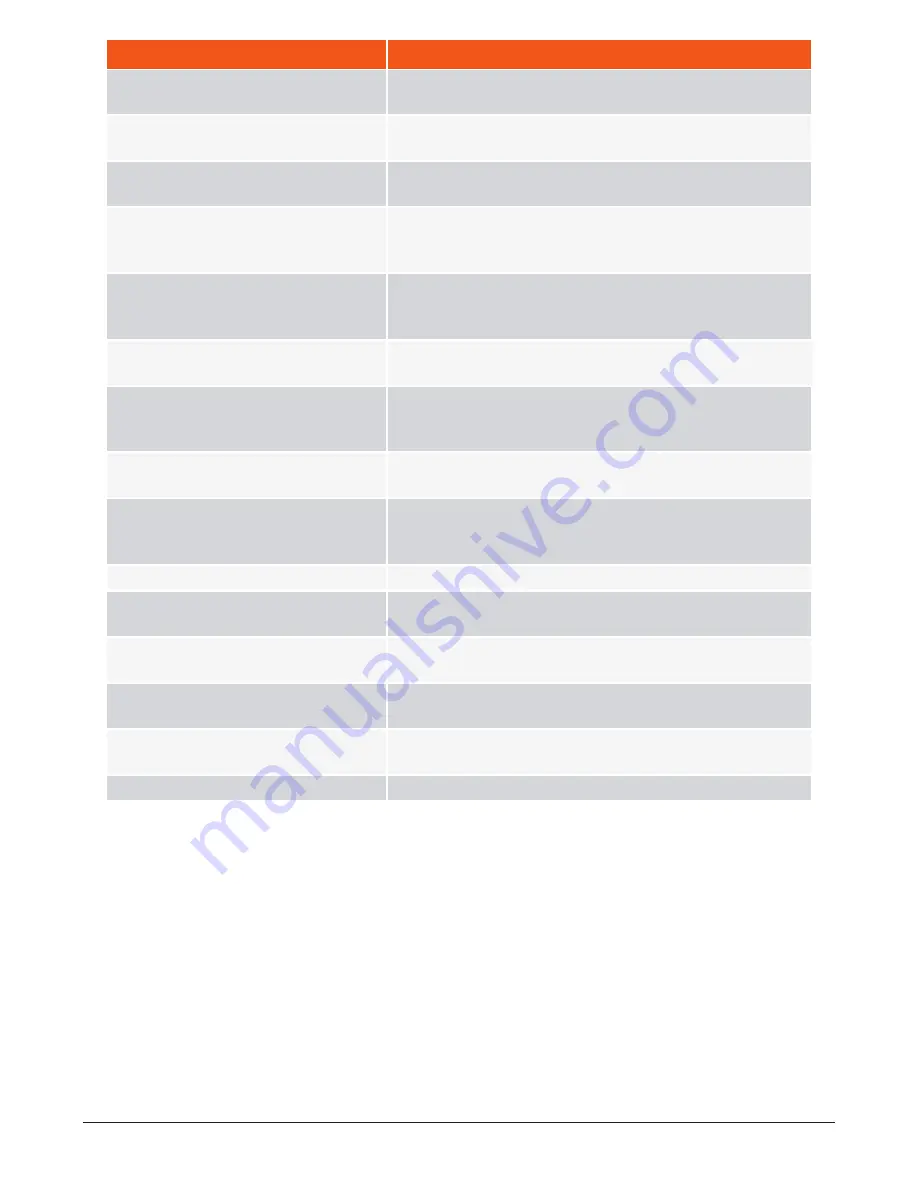

Settings

Explanation

Film release, 2nd

Defines at which of the wrapper rounds the cutters releases the

film, second time

Film release, 3rd

Defines at which of the wrapper rounds the cutters releases the

film, third time

Film release duration

Defines the duration of the cutter film release. Should be adjusted

in context of the cutters speed (manual valve)

Bale drop dwell time

Defines the wrapping tables dwell in lower position during bale

drop. Chosen based on material weight and firmness, as well as

whether the belt rotates

Auto continuation, one roller

Activates automatic reset of the wrapping table belt speed when

wrapping with one roller. Used to maintain the correct overlap

when one roller empties

Feed rollers rotate @ closing

Defines whether the feed rollers rotate during closing. Used to pro-

tect the net/film

wrapping table run during drop

Defines whether the wrapping table belts rotates during the bale

drop. If activated, the bale may roll further away from the

machine

Bale eject additional rotation

Defines an additional rotation of the bale when ejected from the

chamber. Used to place the net/film "tale" on top of the bale

Hopper run during transport

Defines whether the feed hopper runs when the bale is being

transported to the wrapper. May be used to prefill the elevator

before the next bale

Grease amount

Defines the amount of grease pumped to the lubrication points

Delayed hopper start

Defines a delayed start of the hopper after the elevator has star-

ted

Wrapping table run before drop

Defines whether the wrapping table rotates in order to squeeze

the film before bale drop

F25: Augers low speed run

For F25 only: Defines whether the augers rotates then the elev-

ator runs at low speed

F25: Hopper full flow

For F25 only: Defines whether the hopper runs at full speed at all

(both pumps connected)

F25: Hopper full flow delay

For F25 only: Defines a delay before the hopper runs at full speed

6 CONTROL SYSTEM

68

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...