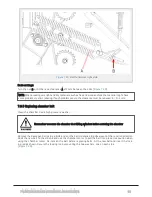

7.7.4 Chain tensioner, elevator F25

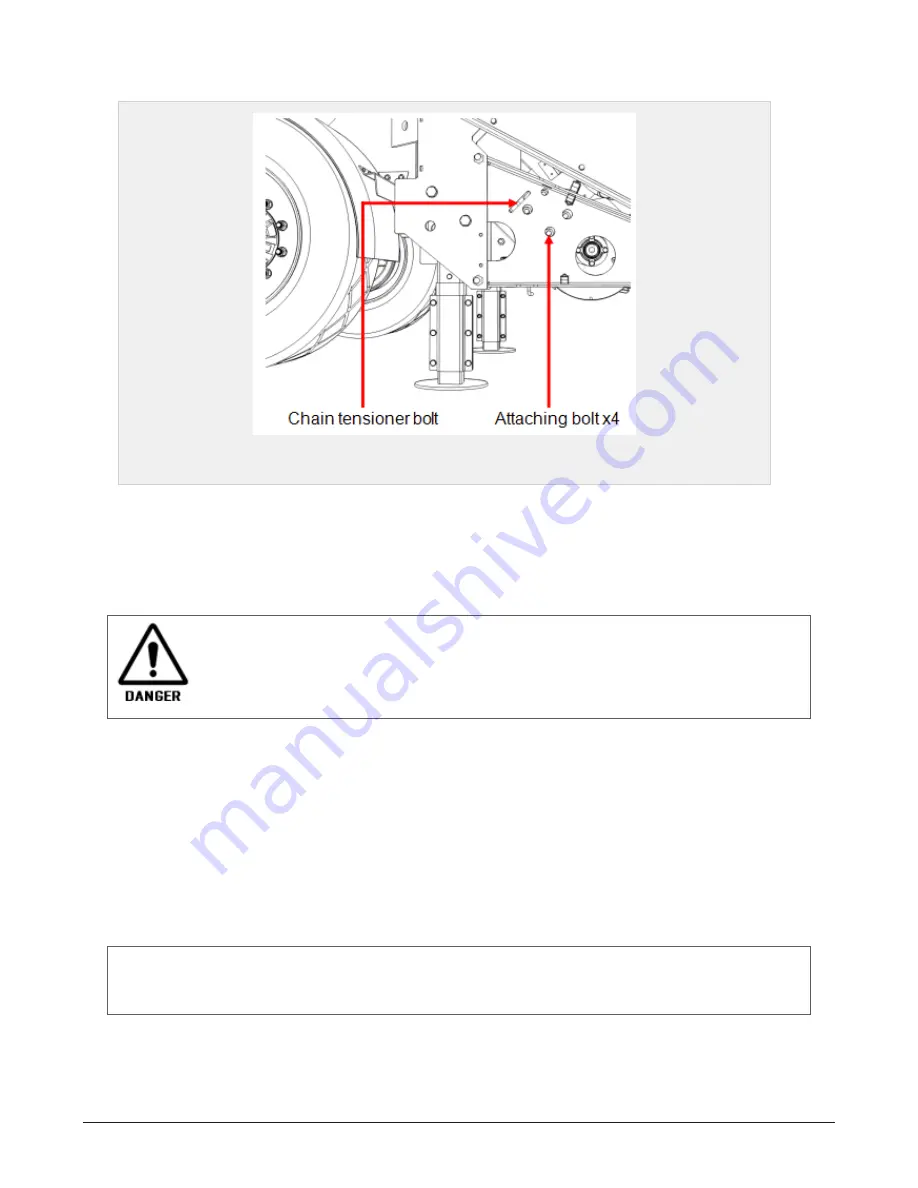

Figure 7.10 :

Chain tensioner F25 elevator

7.7.5 Ball bearings elevator

The rollers in the elevator and belt under should be without deformations and cracks. Check the bearing

clearances without belt tension. Replace worn bearings.

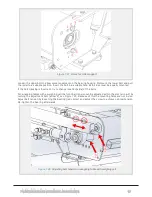

7.8 BALING CHAMBER

All repair and maintenance work inside the chamber is associated with great danger. Secure

the chamber door lifting cylinders, by closing the securing valves on both sides. The machine

must be stopped and PTO disconnected.

7.8.1 Inspection

Chamber - rollers - bearings - belts

The bale chamber must be checked frequently. Before performing a control, the chamber must be properly

cleaned, preferable using a high pressure washer. Check the tracking of the chamber belts and adjust if

needed.

Look for wear on the chamber sidewalls and check the condition of the rollers and rubber belts. The grade

of wear and tear are varying, depending on which material being baled.

Replace damaged rollers and belts if excessively worn. If there is excessive wear on the chamber sidewalls,

Hardox wear plates can be retrofitted on the chamber walls. Contact Orkel AS if relevant.

NOTE: The play in the slide bearings is at the smallest when the compactor is brand new. This may result in

increased temperature in the bearings. The bearings should therefore be checked as they might require addi-

tional lubrication.

7 MAINTENANCE AND MECHANICAL ADJUSTMENTS

78

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...