During control and manual greasing of bearings and bushings the tractor/motor shall not be

running.

NOTE: In extreme cases of heating, a special filler nipple may be used (force lubricate) after removing the

hose from the bearing. Please contact Orkel if this is necessary.

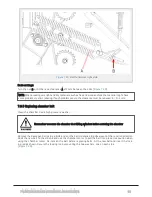

7.8.2 Adjusting the front chamber belt

All adjustment of the belt tracking is done on the right side of the chamber (upper front roller). See

. The belt tracking should not touch the chamber side walls.

If the belt is tracking towards B (

), the distance C (

) must be increased. If the belt is

tracking against A (

) the distance C (

) must be reduced.

Figure 7.11 :

Front chamber belt is

tracking towards A/B

Figure 7.12 :

Front chamber distance C

Loosen the attaching bolts, to allow a movement of the bracket. Loosen the counter nut and adjust the dis-

tance C by turning on the adjustment nut.

Tighten the counter nut and the attaching bolts of the bracket when the belt has a correct tracking.

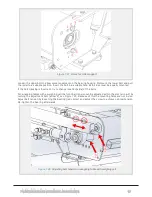

7.8.3 Adjusting the rear chamber belt

The adjustments of the rear chamber belt is done preferably from the right side of the machine. Dismount

the cover and safety net (

) to get access to the adjusting bracket and bolts seen in

.

7 MAINTENANCE AND MECHANICAL ADJUSTMENTS

79

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...