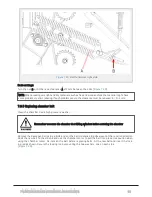

Figure 7.19 :

Belt tensioner, right side

Basic settings:

Turn the nut B, until there’s a clearance A of 1 mm between the coils (

).

NOTE: When pressing very light and dry materials, such as hay and wooden chips, the material might have

some problems to start rotating. If such problem occurs, the clearance must be reduced. A = 0 - 1mm.

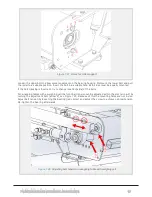

7.8.5 Replacing chamber belt

Clean the chamber. Use a high pressure washer.

Remember to secure the chamber door lifting cylinders before entering the chamber

Remove the damaged belt using a knife and cut the belt crosswise. Be observant of the rotation direction.

Hook the new belt to the old one and use the chamber motor to pull the belt into place. Use caution when

using the chamber motor. De-tension the belt before replacing belts. Fit the new belt and insert the lock-

ing rod as shown. Secure the locking rod by mounting the two washers, one on each side

(

).

7 MAINTENANCE AND MECHANICAL ADJUSTMENTS

83

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...