8.2.1 Refilling the oil reservoir

The grease lubrication system is sensitive to the influence of external contamination, such as dust and

dirt. Keep the cap on and refill through the male sleeve nipple (no. 11,

section 8.1.3 "Beka max grease lub-

) when refilling grease.

NOTE: Always keep the reservoir, male sleeve nipple and pump clean.

NOTE: We recommend that you purchase grease in larger containers. Pails of 20 litres/16kg’s in combination

with air or electrical operated tools for refilling. Standard grease gun with 0,5 litres cartridges might also be

used.

A grease gun for cartridges, with special nipple might be ordered as an option. Part number: 58086

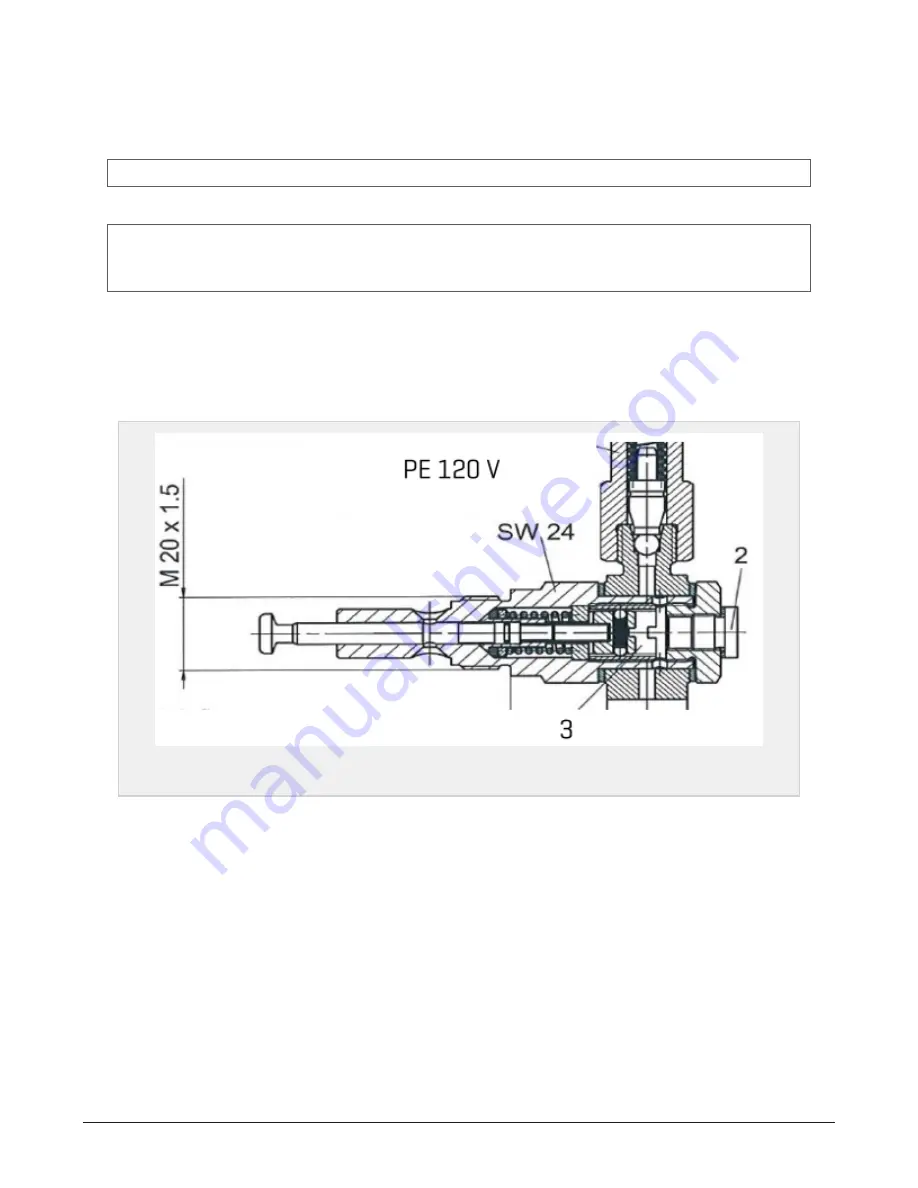

8.2.2 Adjusting the amount of grease

The grease lubrication system is set to a maximum delivery of 0,29cm³/rev. However one of the pumps is

adjustable (PE120V).

Figure 8.4 :

Grease pump adjustment

Remove plug (item 2,

) to get access to adjusting screw (3). By turning the screw clockwise, the

amount is reduced. 1/2 turn on the adjusting screw reduces the grease added by 0,013cm³. Please contact

Orkel Compaction if you have any questions.

It is also possible to regulate the grease amount for the control unit. Adjustable from 100% down to 40%.

8.2.3 Bleeding the grease system

If the level in the reservoir is too low, it can be necessary to bleed the system after refilling.

1. Disconnect the plastic tube, mounted under the pressure relief valve on the pump.

2. Activate the function greaser in the control box, until there is a smooth and constant flow from the

outlet.

3. Reconnect the plastic tube to its original position.

8 LUBRICATION

99

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...