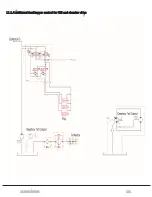

Left

Middle-left

Middle

Middle-

right

Right

Left

E-stop 4 [Bl]

-

To X2.16 (E-stop)

E-stop relay, A1

E-stop 2 [Y]

E-stop 3 [R]

E-stop 3 [Y]

E-stop 4 [Y]

E-stop 2 [R]

E-stop 1 [Y]

E-stop 1 [R]

To X10.3

-

S1 override switch [Y]

To X5.19

Check valve [1]

Hopper switch [Y]

Charge lamp [Y]

Alternator [R]

LED lamp switch

[Y]

LED lamp [R]

LED lamp [R]

LED lamp [R]

LED lamp switch

[R]

Hopper switch [R]

Jumper

Charge lamp [R]

To X10.2

F.storage switch

1 [R]

F.storage switch 2 [R]

S1 override switch [R]

F.storage switch

1 [Y]

F.storage switch 2 [Y]

F.storage valve [1]

Prog. cable [Y]

-

Jumper

-

Resistor 120 Ohm

Display unit [Wh] -

Chamber CU 4.2

Wrapper CU 4.2

Display unit [Bk] -

Jumper

Chamber CU 4.6

Wrapper CU 4.6

Prog. cable [R]

-

-

Resistor 120 Ohm

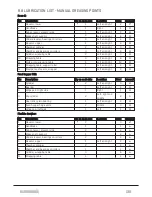

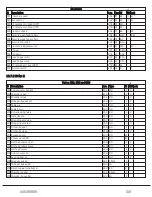

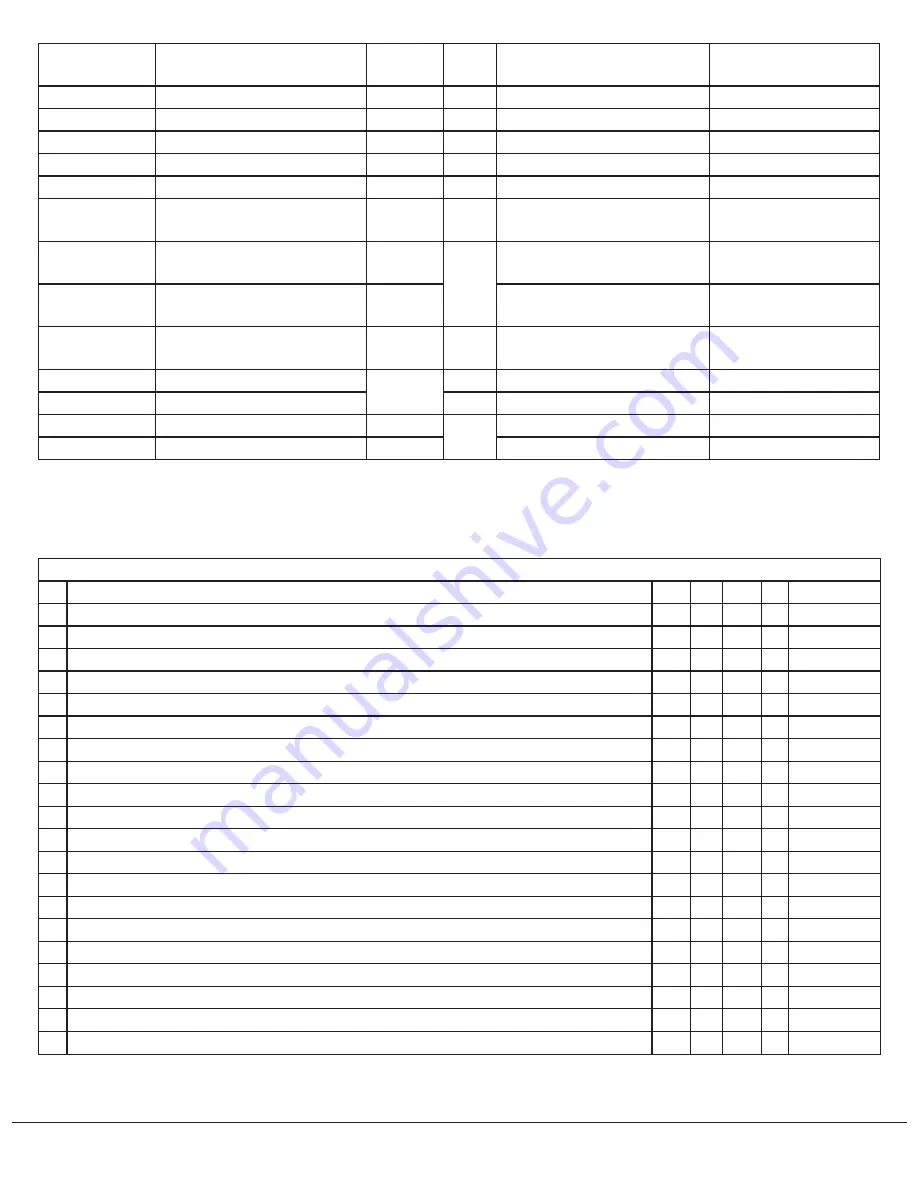

10.7 INPUTS AND OUTPUTS SORTED BY NUMBER

10.7.1 IO list 1

All sensors

ID

Description

Loc. Type Hi

Mid Low

S01 Bale on wrapping table

X5.19 DI

A.Wh

S03 Table middle position

X5.20 DI

Bk

Bl Br

S05 Wrapping arm home position

X6.19 DI

A.Bk A.Y A.R

S07 E-Stop redundancy input

X2.16 DI

X13.3

S08 Wrapping arm stop

X6.20 DI

A.Br

S09 Table lower position

X6.22 DI

Bk

Bl Br

S10 Table upper position

X6.23 DI

Bk

Bl Br

S11 Film sensor 1

X7.19 PI

A.Bl

S12 Film sensor 2

X7.20 PI

A.Gn

S14 Oil temperature

X5.12 AI

Bk

S16 Chamber dampening

X3.13 DI

Bk

Bl Br

S17 Chamber opened

X1.19 DI

Bk

Bl Br

S18 Chamber closed

X1.20 DI

Bk

Bl Br

S19 Feed rollers opened

X2.19 DI

Bk

Bl Br

S20 Feed rollers closed

X2.20 DI

Bk

Bl Br

S22 Net knife closed

X3.14 DI

Bk

Bl Br

S27 Oil level

X6.16 DI

Bk

Bl Br

S28 Grease level

X6.17 DI

Bk

Bl Br

S29 Feed hopper US-sensor

X3.6 AI

Gy

Bl Br

S30 Chamber pressure

X3.5 AI

Wh

Br

10 ELECTRICS

118

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...