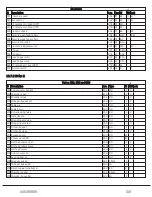

10.10 SENSOR LIST AND FUNCTION

Inputs on controllers for standard system

No.

Description

Type

Brand & type

Range

Comment

S1

Bale on table ultrasound

Digital ultrasound

Microsonic mic+130/D/TC

100...2000 mm

Default 70 cm

S3

Table in middle position

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S5

Wrapping arm in home pos-

ition

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S7

E-stop redundancy input

Switch NC

S8

Wrapping arm collision stop

Switch NC

S9

Table in low position

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S10 Table in high position

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S11 Wrapper film roller 1

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S12 Wrapper film roller 2

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S14 Oil temperature

Analogue PT1000

Fuehler Systeme

EF5/E-20/5 PT1000

1573...803Ω,

-50..150 °C

S16 Chamber dampening

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S17 Chamber open position

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S18 Chamber closed position

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S19 Feed rollers open position

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

2 sensors in

series

S20 Feed rollers closed position

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S22 net knife in closed position

Inductive PNP

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S27 Hydraulic oil level

Photoelectric level

PNP

Carlo Gavazzi VP04EP

S28 Grease level

Switch NC (at full

level)

S29 Hopper ultrasound

Analogue ultra-

sound

Pepperl&Fuchs UC2000-30GM70-

IE2R2-V15

4 - 20mA, 100...2000

mm

S30 Chamber pressure

Analogue pressure

4 - 20mA,

0...600 bar

S31 Chamber speed

Inductive PNP

(pulse)

3...8 mm

S32 Net/film failure detection

Inductive PNP

(pulse)

3...8 mm

Optional

S33

RF Remote control - stop

machine

Switch NO

Optional

S34

RF Remote control - bale

drop

Switch NO

S35 Elevator speed

Inductive PNP

(pulse)

Pepperl&Fuchs NBB8-18GM50-E2-V1 3...8 mm

S37

Remote control - feed rollers

open

Switch NO

S38

Remote control - feed rollers

close

Switch NO

S39

Remote control - start

film/net

Switch NO

S41 Elevator pressure sensor

Analogue

IFM PT5401

4 - 20 mA, 0...250 bar

10 ELECTRICS

125

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

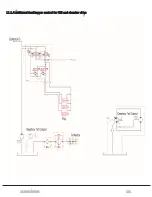

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

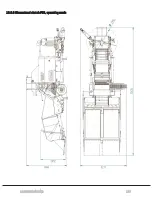

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...