4.3.2 Checkpoints while baling

No Checkpoint prior to baling

1

Continuously observe all moving parts and functions.

2

Check the tracking of both chamber belts (leveling will affect the tracking).

3

Check the greasing pump function.

4

Check the chain lubrication system (Dry chains?).

5

Check the condition and cleaning of chamber rollers. Too much material on the rollers will affect the track-

ing of the chamber belts.

6

Avoid overfilling of the space between the elevator and sub conveyor. (Easily avoided by controlling the

material amount fed into the elevator).

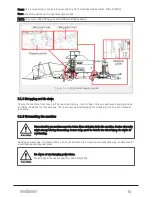

4.4 BREAK-IN PERIOD

The first 50 hours of operation are considered to be the break-in period.

NOTE: Before the compactor is shipped from the factory, Orkel has performed a thorough quality control and

made a test run. The test run is done without any material. The need of some adjustments during first start

up is to be expected, depending on the material being baled.

4.4.1 Precautions during the break-in period

When the compactor is brand new, there are a couple of things that need special attention from the oper-

ator. The tensioning of the elevator chain must be checked and, if necessary, readjusted during the first

three hours of operation.

4.4.2 After the first 50 hours of operation

Change the oil, and all oil filters.

4 OPERATION

43

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...