Oils can be hot.

Some pressure can remain in the hydraulic system/hoses/pipes, even though the machine is

shut down.

IMPORTANT: Always change filters when changing the hydraulic oil!

7.14.1 Changing oil and filter

Hydraulic oil

1. Heat the oil up to about 30°C.

2. Slightly tilt the compactor towards the drain plug. The plug is placed on the underside of the tank.

3. Shut down the machine and disconnect the PTO.

4. Place an empty container beneath the drain hole.

5. Remove the drain plug.

6. Drain until empty. Approximately 130 L of oil.

7. Clean up the oil spill.

8. Reinsert the drain plug (replace sealing if necessary).

9. Change the oil filter according to the “Filter”-procedure below.

10. Drain the oil and remove the oil filter on the collector according to the “Collector and cooler”-pro-

cedure.

11. Refill. A sticker on the oil tank indicates the applied oil type.

12. Check the oil level.

13. Run the compactor for a while, top up if necessary.

14. Dispose with the old oil according to environmental regulations.

Collector and cooler

1. Place an empty container beneath the drain hole.

2. Remove the drain plug.

3. Drain until empty. Approximately 10 L of oil.

4. Clean up the oil spill.

5. Reinsert the drain plug (replace sealing if necessary).

6. Change the oil filter according to the “Filter”-procedure.

Changing filter

1. Locate the desired filter to be replaced.

2. Place an empty container beneath the filter insert.

3. Remove the filter.

7 MAINTENANCE AND MECHANICAL ADJUSTMENTS

93

Summary of Contents for Dens-X Compactor

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 103: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 103...

Page 104: ...8 7 2 Feed hopper F25 8 LUBRICATION 104...

Page 105: ...8 7 3 Flexible drawbar 8 LUBRICATION 105...

Page 109: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 109...

Page 110: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 110...

Page 111: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 111...

Page 112: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 112...

Page 124: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 124...

Page 128: ...11 1 1 Complete diagram 11 HYDRAULICS 128...

Page 129: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 129...

Page 130: ...11 1 3 Plastic tying unit sub conveyor and feed hopper 11 HYDRAULICS 130...

Page 131: ...11 1 4 Additional feed hopper control for F25 and chamber drive 11 HYDRAULICS 131...

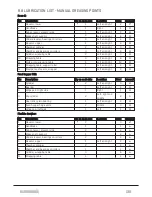

Page 133: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for Dens X 11 HYDRAULICS 133...

Page 137: ...12 6 3 Dimensional sketch F25 operating mode 12 SPECIFICATIONS 137...

Page 138: ...12 6 4 Dimensional sketch F25 transport mode 12 SPECIFICATIONS 138...

Page 142: ...M Maintenance 13 69 71 INDEX 142...