Oil type

Motor oil SAE 10W - 30, 15W - 40

Oil consumption

6ml each bale on the table. 0.3 l/h (@ 50 bales/h)

Volume container

4,2 l

12.4 HYDRAULIC SYSTEM

Chamber drive:

280/340 bar (SW/relief valve)

Sub-conveyer, feed hopper and film system:

180 bar

Elevator and chamber door:

170 bar

Wrapper

150 bar

F25 additional pump (flip and feed hopper):

190 bar

12.5 WHEELS AND TYRES

Tyre dimension:

385/65 R 22,5

Rim dimension:

11,75 x 22,5, 10-bolt

Inflation pressure: 8,0 bar / 800 kPa / 116 psi (lb/in²) Wheel nuts torque:

8,0 bar / 800 kPa / 116 psi (lb/in²)

Wheel nuts torque:

450 Nm

12.6 DIMENSIONS AND WEIGHT

12.6.1 Measurements

Net weight (F10, telescopic drawbar):

9660 kg

Allowed total weight:

12500 kg

Allowed vertical load on drawbar:

2500 kg

Height (F10, telescopic drawbar), transport mode:

4100 mm

Height (F10, telescopic drawbar), operating mode:

3900 mm

Length (F10, telescopic drawbar), transport mode:

8740 mm

Length (F10, telescopic drawbar), operating mode:

10770 mm

Width (F10, telescopic drawbar), transport mode:

2550 mm

Width (F10, telescopic drawbar), operating mode:

3710 mm

Chamber size:

Width 1200 mm x Diameter 1150 mm

Bale volume

1,25 m³

Feed hopper volume:

25 m³ (F25) / 10 m³ (F10)

12.6.2 Power requirements

120hp / 90 kW (diesel engine)

90hp / 75 kW (electric motor)

12 SPECIFICATIONS

131

Summary of Contents for MP2000-X

Page 14: ...1 6 DECLARATION OF CONFORMITY 1 GENERAL 14...

Page 98: ...8 6 4 Gearbox and gears for hydraulic motors Gear oil Renolin unisyn CLP 220N 8 LUBRICATION 98...

Page 99: ...8 7 MANUAL LUBRICATION CHARTS 8 7 1 The compactor 8 LUBRICATION 99...

Page 100: ...8 7 2 Feed hopper F10 8 LUBRICATION 100...

Page 101: ...8 7 3 Telescopic drawbar 8 LUBRICATION 101...

Page 105: ...10 1 MAIN POWER SUPPLY E STOP SWITCHES AND ELECTRICAL CABINET 10 ELECTRICS 105...

Page 106: ...10 2 ELECTRICAL CABINET POWER SUPPLY RAIL 10 ELECTRICS 106...

Page 107: ...10 3 SENSORS AND MANUAL CONTROLS 10 ELECTRICS 107...

Page 108: ...10 4 VALVES FAN MOTORS AND PUMPS 10 ELECTRICS 108...

Page 120: ...10 9 SENSOR OVERVIEW 10 ELECTRICS 120...

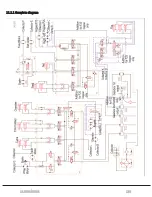

Page 124: ...11 1 1 Complete diagram 11 HYDRAULICS 124...

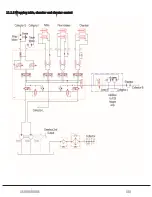

Page 125: ...11 1 2 Wrapping table chamber and elevator control 11 HYDRAULICS 125...

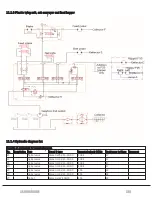

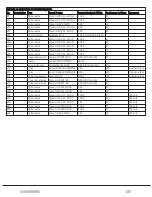

Page 128: ...11 2 VALVE OVERVIEW 11 2 1 Valve chart for MP2000 X 11 HYDRAULICS 128...

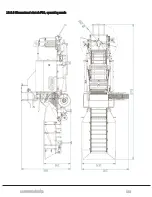

Page 132: ...12 6 3 Dimensional sketch F10 operating mode 12 SPECIFICATIONS 132...

Page 133: ...12 6 4 Dimensional sketch F10 transport mode 12 SPECIFICATIONS 133...

Page 137: ...M Maintenance 13 65 67 INDEX 137...